Horizontal depolymerization reaction kettle for polylactic acid production

A polylactic acid and reaction kettle technology, which is applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problems of chemical reagent contact and affecting the production of polylactic acid. , to increase the speed and avoid the effect of material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

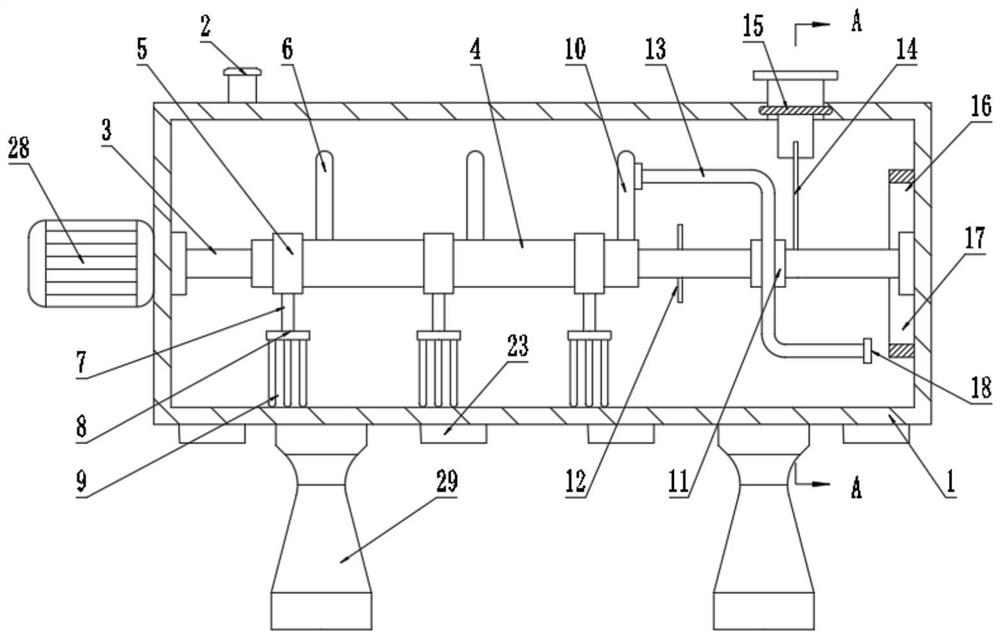

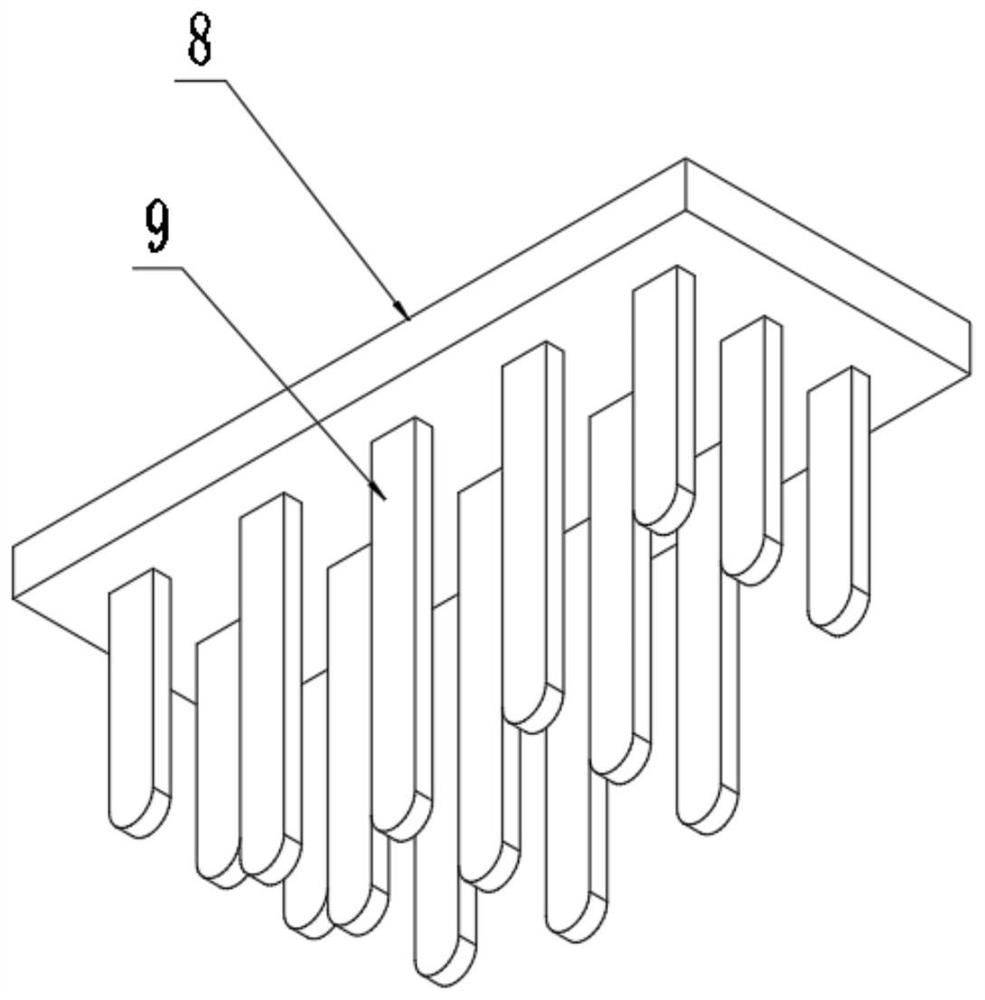

[0023] see figure 1 , in the embodiment of the present invention, a horizontal depolymerization reactor for polylactic acid production comprises a depolymerization reactor 1, a feeding pipe 2 and a heater 23, and the heater 23 is arranged at the bottom of the depolymerization reactor 1, The feeding pipe 2 is arranged on the top of the depolymerization reaction tank 1, and the feeding pipe 2 is connected and fixed with the depolymerization reaction tank 1. The feeding pipe 2 is used to add materials to the depolymerization reaction tank 1, and the depolymerization reaction tank 1 is provided with There is a flattening structure, and the flattening structure is connected with a ventilation structure. Since the material is added from the feeding pipe 2, the material will be accumulated under the feeding pipe 2. The flattening structure is used to evenly accumulate the materials accumulated under the feeding pipe 2. The material is evenly distributed in the depolymerization reacti...

Embodiment 2

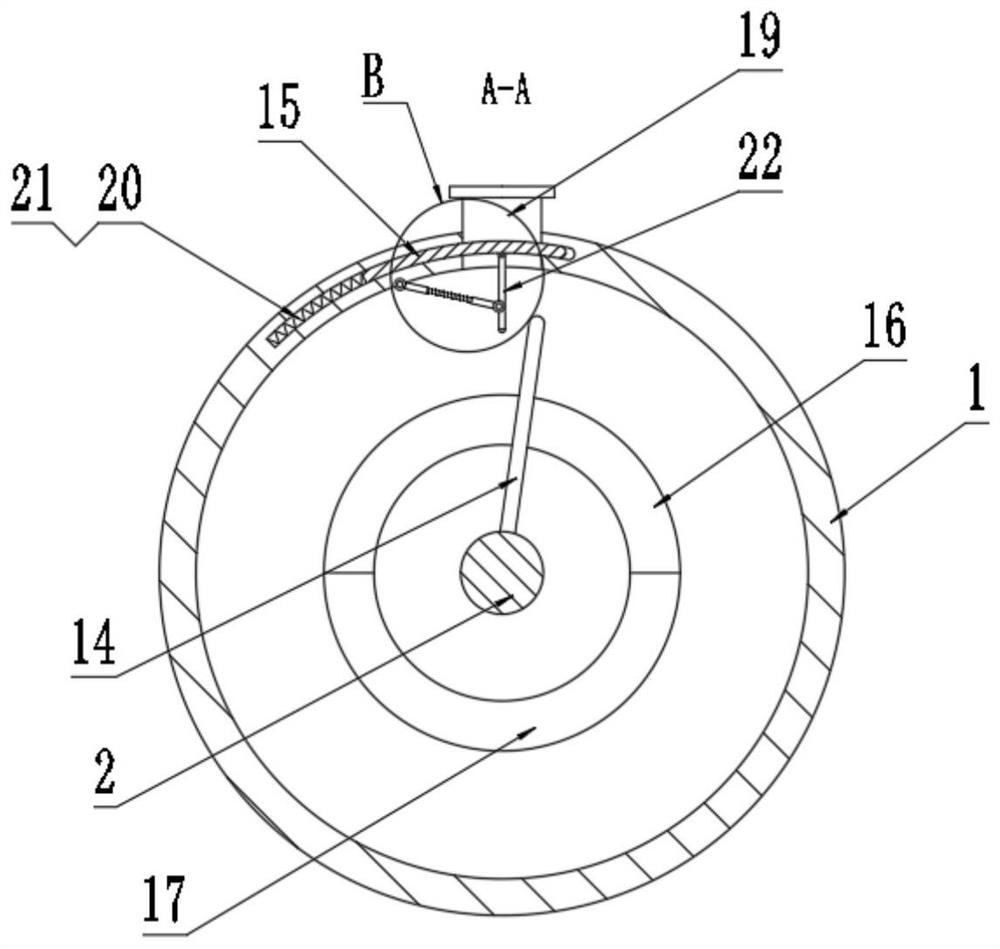

[0029] see figure 1 and Figure 3-4 , in an embodiment of the present invention, a horizontal depolymerization reaction tank for polylactic acid production, the ventilation structure includes an arc-shaped sealing plate 15, a vent hole 19 and an opening plate 22, and the vent hole 19 is opened in the depolymerization reaction tank The top of 1 is away from the side of the feeding pipe 2, and the two sides of the air hole 19 are provided with arc-shaped grooves 21, and the arc-shaped sealing plate 15 is slidingly connected in the arc-shaped groove 21, and the opening plate 22 and arc-shaped Shaped sealing plate 15 is hinged, and is positioned at the below of arc-shaped sealing plate 15, and opening plate 22 controls arc-shaped sealing plate 15 to move to one side, and arc-shaped sealing plate 15 can open air hole 19 to ventilate, and depolymerization reaction tank 1 The gas generated inside is exhausted, and when the arc-shaped sealing plate 15 closes the air hole 19, heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com