Optical lens shell maintenance device

An optical lens and housing technology, which is applied in the field of optical lens housing maintenance devices, to achieve the effect of preventing dust from entering the interior of the outer frame, avoiding influence, and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

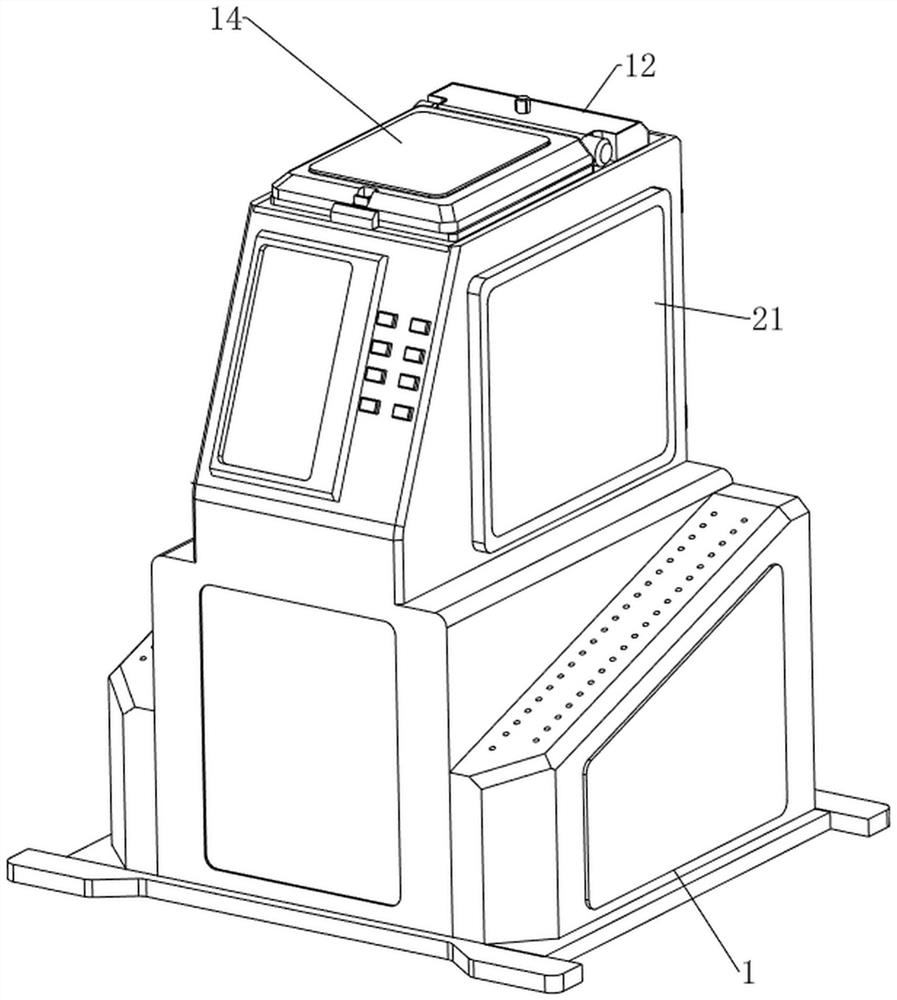

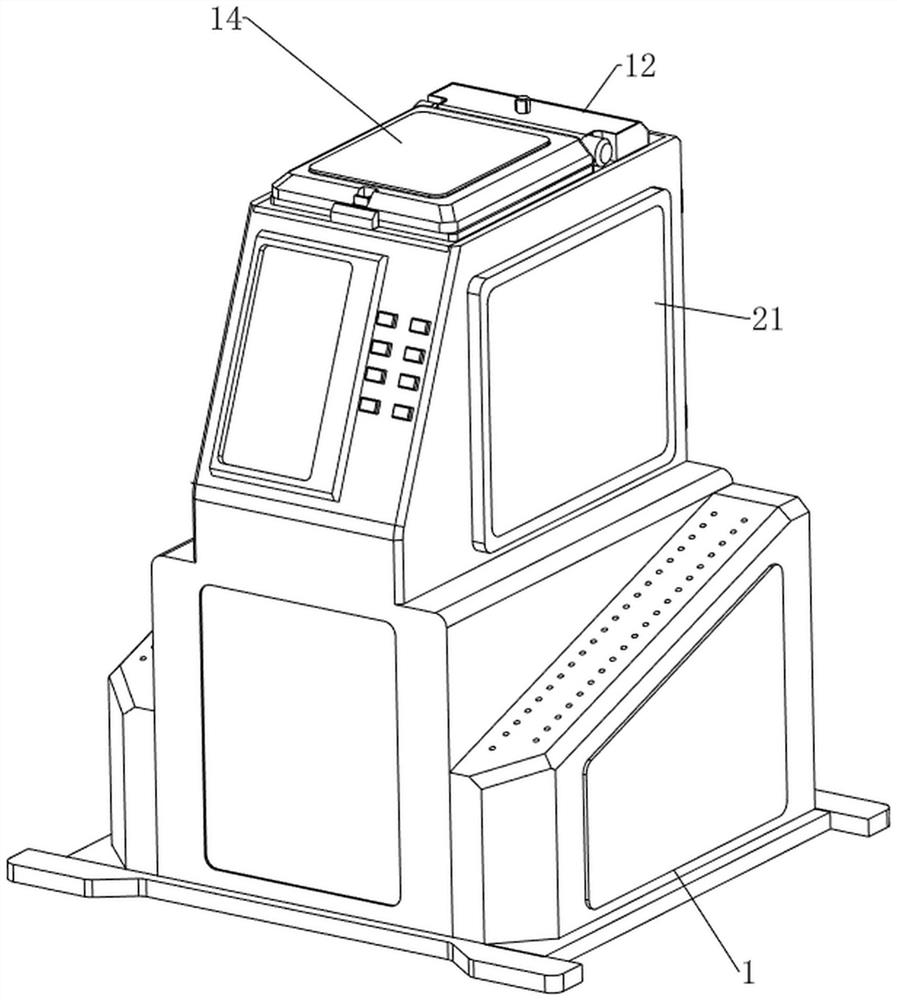

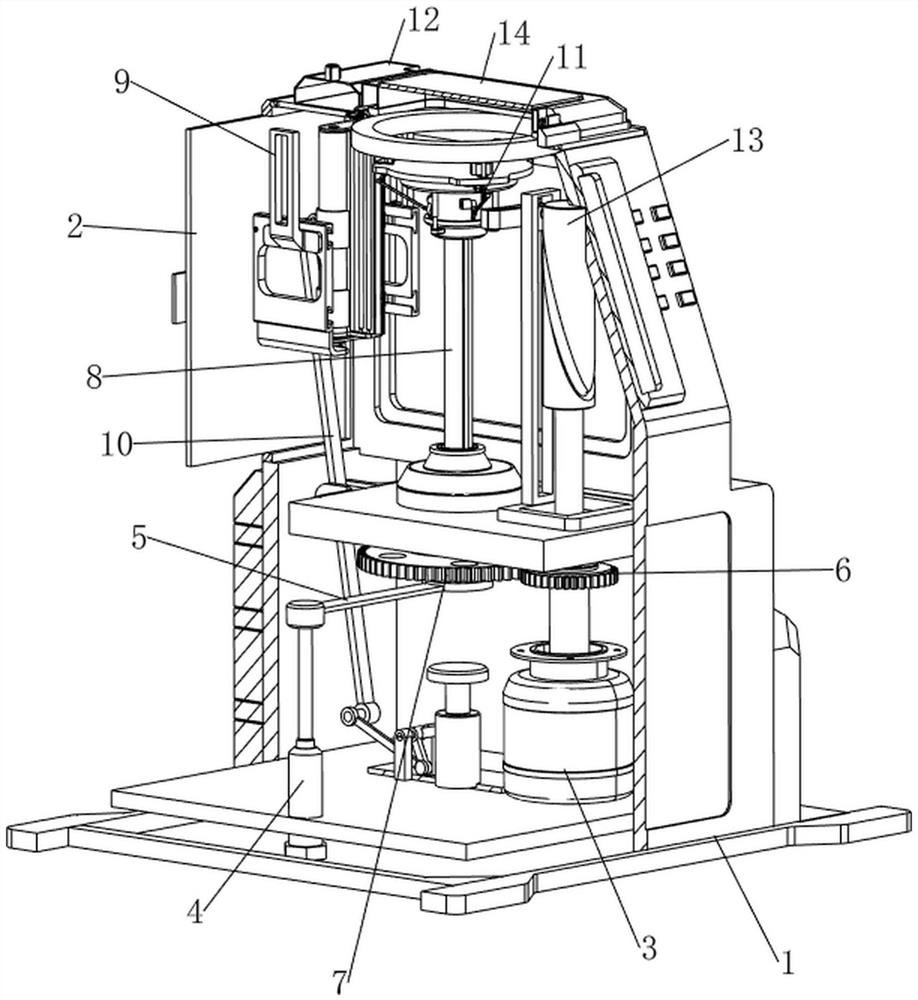

[0094] see figure 1 , figure 2 , image 3 and Figure 4 , a maintenance device for an optical lens housing, comprising an outer frame 1, a revolving door 2, a first transparent glass 21, a motor 3, a cylinder 4, a pressing plate 5, a first full gear 6, a second full gear 7, and a support frame 8 , a cleaning mechanism 9, a pushing mechanism 10 and a limit mechanism 11, the front side of the top of the outer frame 1 has a discharge port, the rear upper side of the outer frame 1 is hinged with a revolving door 2, and the left and right sides of the upper part of the outer frame 1 are symmetrically embedded. The first transparent glass 21, the first transparent glass 21 is convenient for people to observe the progress of the work, the front side of the inner bottom of the outer frame 1 is fixedly connected with a motor 3 by bolts, the output shaft of the motor 3 is connected with the first full gear 6 by a key, and the outer frame 1 The rear side of the middle part is connect...

Embodiment 2

[0100] On the basis of Example 1, please refer to figure 1 , Figure 13 , Figure 14 and Figure 15 , also includes a storage mechanism 12, the storage mechanism 12 is used to store the maintenance fluid, the storage mechanism 12 includes a storage box 121, a box cover 122, a hose 123, a pressing rod 124 and a third telescopic spring 125, and the rear side of the top of the outer frame 1 A storage box 121 is provided. The storage box 121 is used to store maintenance fluid. A detachable box cover 122 is installed in the middle of the top of the storage box 121. The box cover 122 is used to close the storage box 121. A hose 123 is provided in the middle of the front lower side of the storage box 121. , the hose 123 passes through the discharge port and is connected to the rear upper side of the discharge pipe 911, and the middle part of the front lower side of the storage box 121 is slidably connected with a pressing rod 124. The tube 123 is clamped, and two third telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com