Cleaning and sorting device for coal mine

A sorting device and coal mine technology, applied in the field of coal mine equipment, can solve problems such as uneven ash content, unclean coal mine cleaning, and large ash content in water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

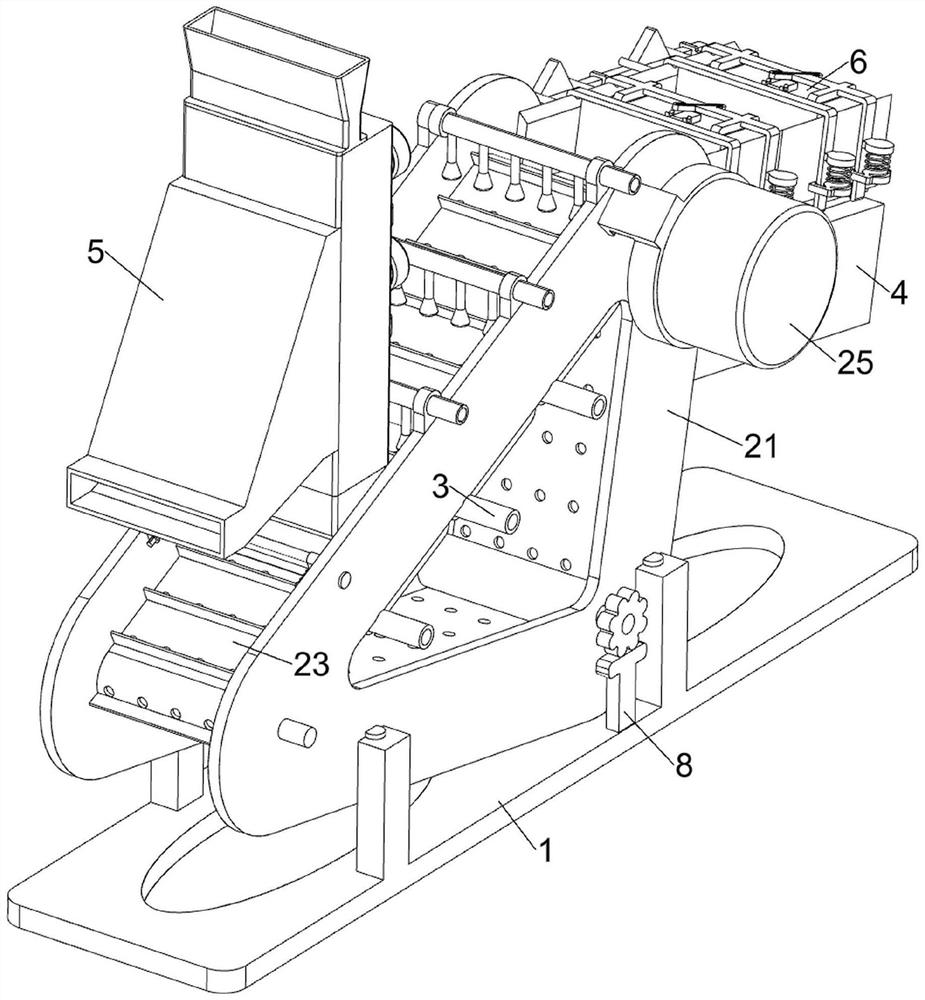

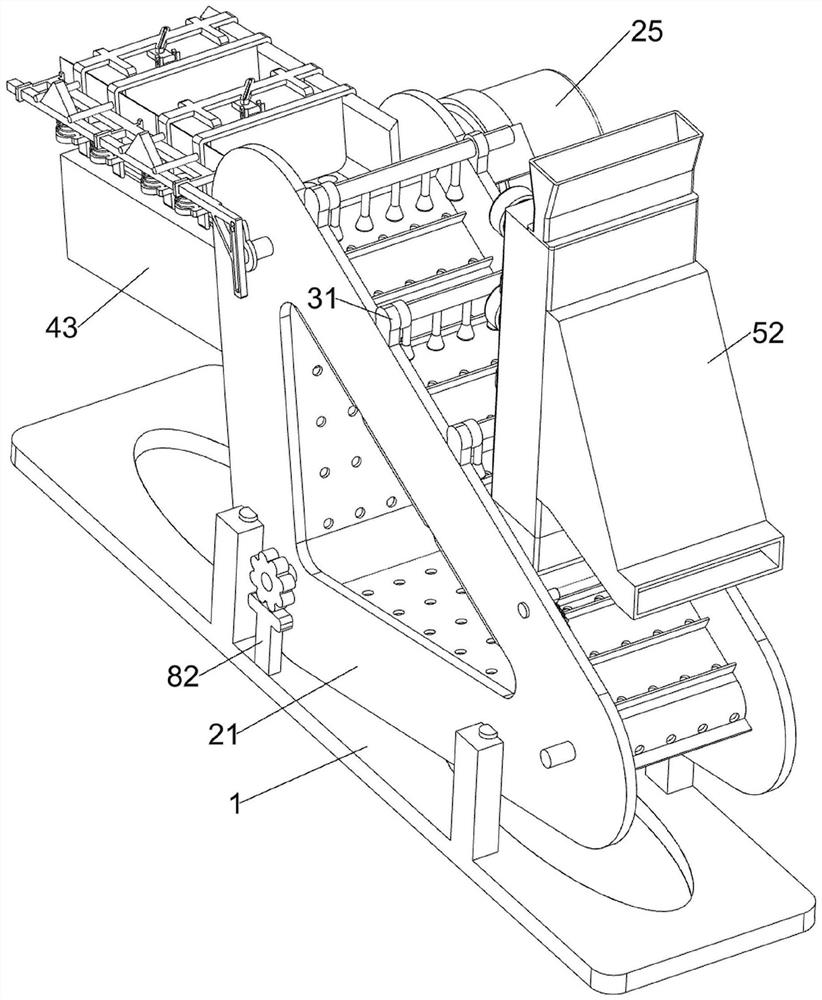

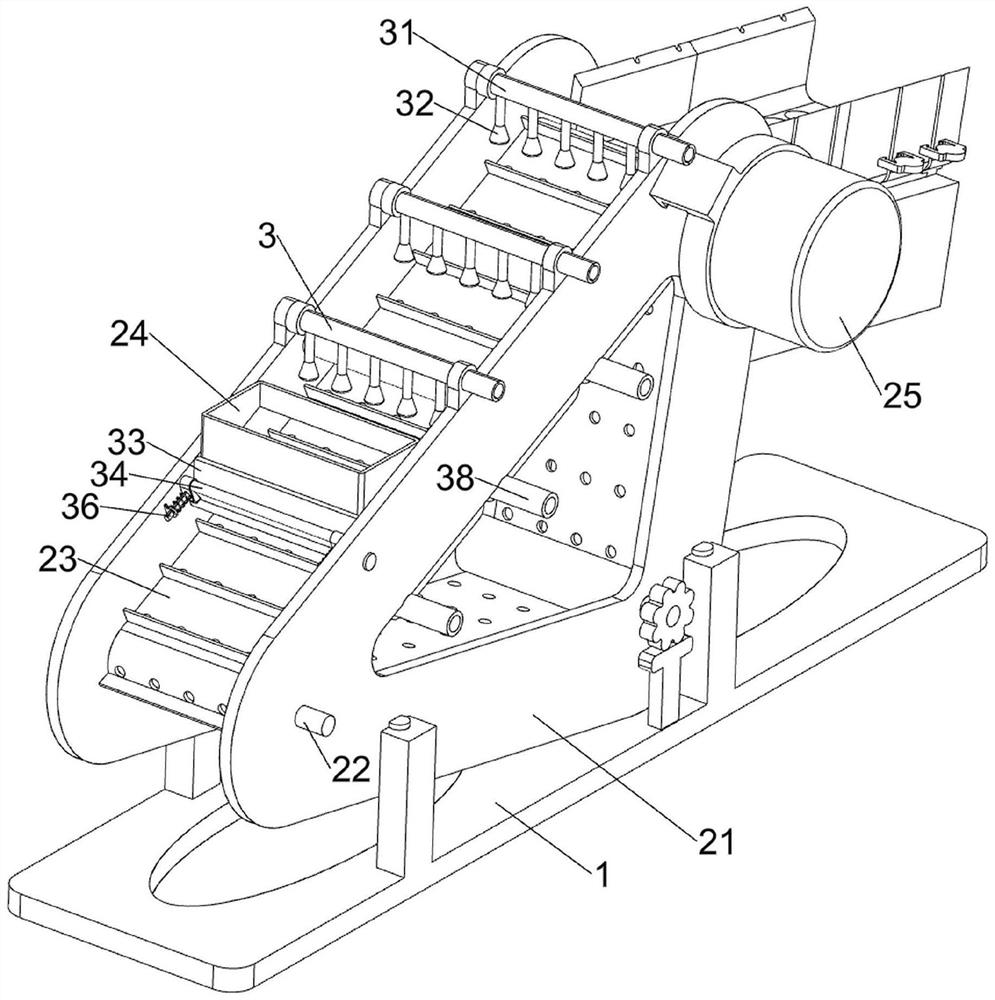

[0044] A coal mine cleaning and sorting device, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 11 , Figure 12 , Figure 15 As shown, it includes a limited bottom frame 1, a sliding support frame 21, a drive roller 22, a perforated conveyor belt 23, a rectangular pouring frame 24, a stepping motor 25, a coal block layer cleaning assembly 3 and a coal block separation assembly 4 , a sliding support frame 21 is slidably connected to the limit bottom frame 1, and a transmission roller 22 is rotatably connected to the sliding support frame 21 in a triangular distribution, and a perforated conveyor belt 23 is connected to the three transmission rollers 22 in a common transmission type. The perforated conveyor belt 23 is used to transport the coal mine upwards. A rectangular pouring frame 24 is fixedly installed on the sliding support frame 21. A stepping motor 25 is fixedly installed on the front side of the sli...

Embodiment 2

[0051] On the basis of Example 1, such as Figure 8 , Figure 9 , Figure 10 As shown, it also includes a dry coal ash separation assembly 5, the top of the rectangular pouring frame 24 is fixedly installed with a dry coal ash separation assembly 5, the dry coal ash separation assembly 5 is used to separate and export the dry coal ash, and the dry coal ash separation The assembly 5 includes a rectangular opening frame 51, an outlet opening frame 52, an air flow pouring frame 53, a T-shaped support frame 54, an air pump 55, a limit pouring frame 56 and a collision plate 57, and the rectangular pouring frame 24 is fixedly installed on the top There is a rectangular opening frame 51, the left side of the rectangular opening frame 51 is fixedly connected with an export opening frame 52, and the export opening frame 52 is used to export coal ash, and the right side of the rectangular opening frame 51 is fixedly connected with two airflows to pour into Frame 53, the middle part of...

Embodiment 3

[0054] On the basis of Example 1, such as Figure 11 , Figure 12 , Figure 13 , Figure 14 As shown, it also includes a push separation assembly 6, the small hole screen frame 41 and the large hole screen frame 42 are all slidably connected with a push separation assembly 6, and the push separation assembly 6 is used to push the coal mine to quickly sort it, push The separation assembly 6 includes a slide rail frame 61, a first return spring 611, a sliding baffle frame 62, a second return spring 621, a fixed opening limit frame 63, a grooved frame with protrusions 64, a transmission frame 65, Slotted push frame 66 and sliding partition frame 67, slide rail frame 61 is slidably connected on the small hole screen frame 41, and slide rail frame 61 is slidably connected on the large hole screen frame 42, and slide rail frame 61 is connected with aperture A pair of first return springs 611 is connected between the screen frames 41, a pair of first return springs 611 is also con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap