Burr cleaning equipment for aluminum casting

A technology for cleaning equipment and aluminum castings, which is applied in the field of burr cleaning equipment for aluminum castings, can solve problems such as cleaning difficult burrs, and achieve the effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-7 The application is described in further detail.

[0037] The embodiment of the present application discloses a burr cleaning device for aluminum castings.

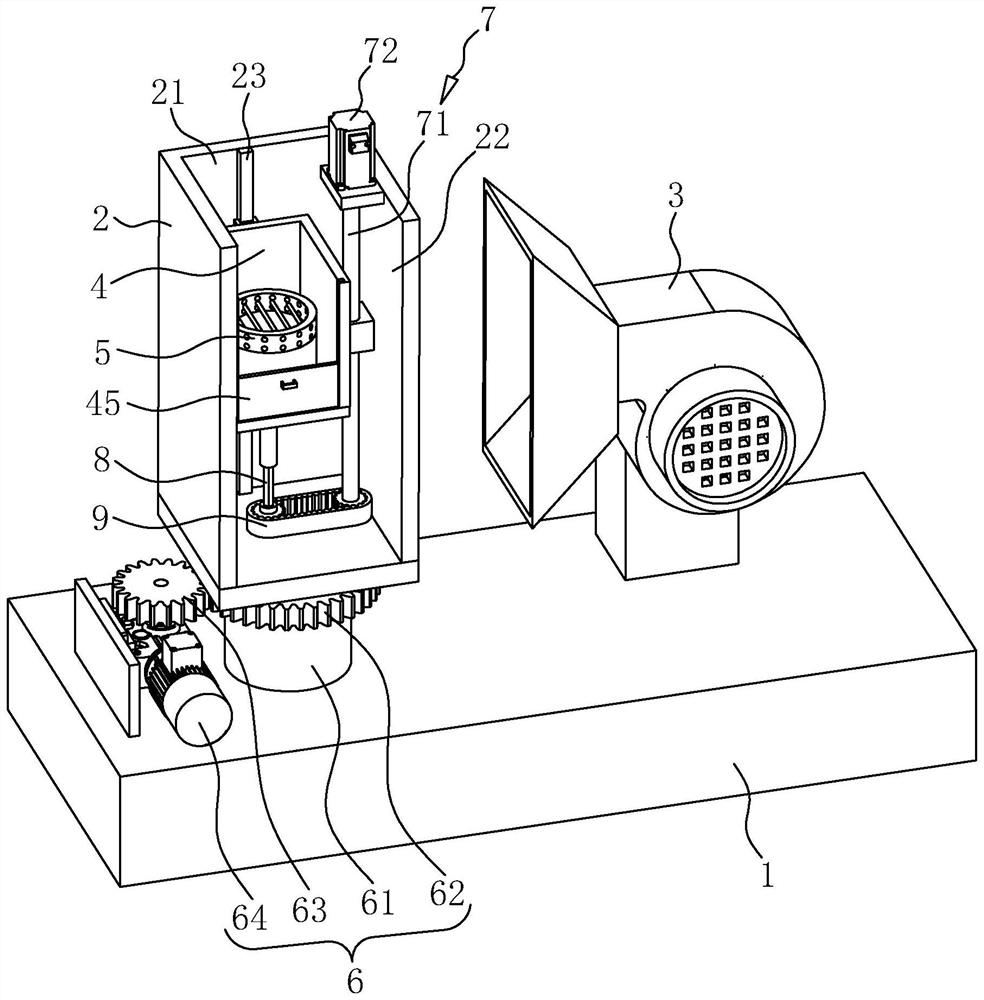

[0038] refer to figure 1 The burr cleaning equipment for aluminum castings includes a base 1, a rotating box 2 is arranged on the top of the base 1, and a docking port 21 is opened on the top of the rotating box 2, and the docking port 21 is docked with the discharge end of the production line of aluminum castings. One side of case 2 has air inlet 22. A blower 3 is fixedly connected to the base 1, and the blower 3 is located at one side of the rotary box 2, and the air outlet of the blower 3 is arranged toward the rotary box 2.

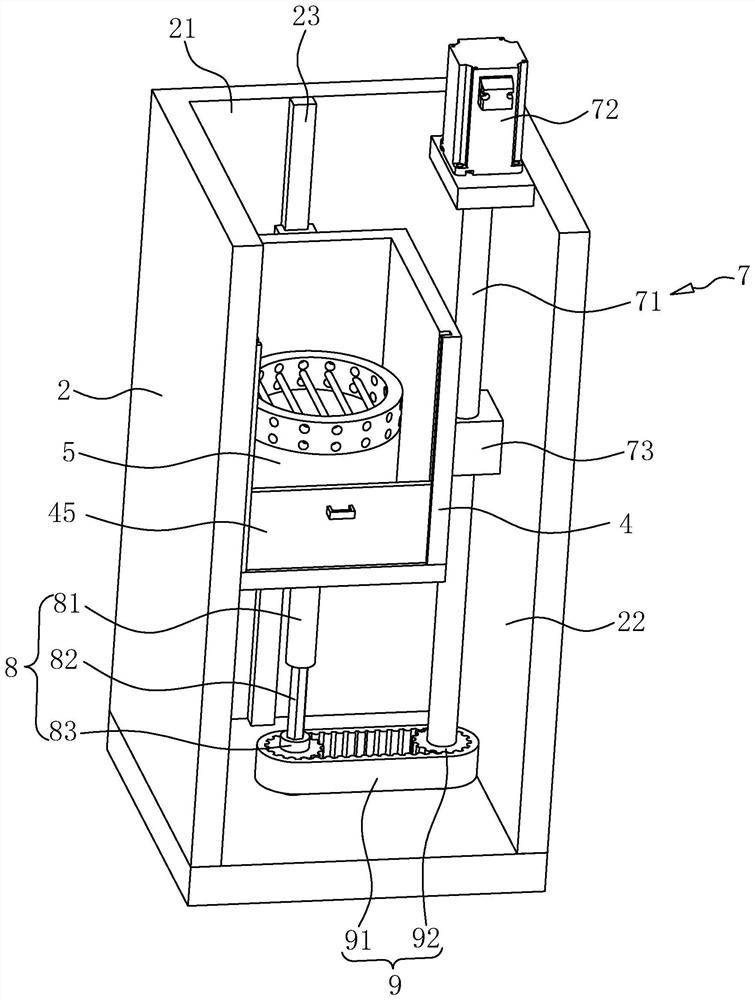

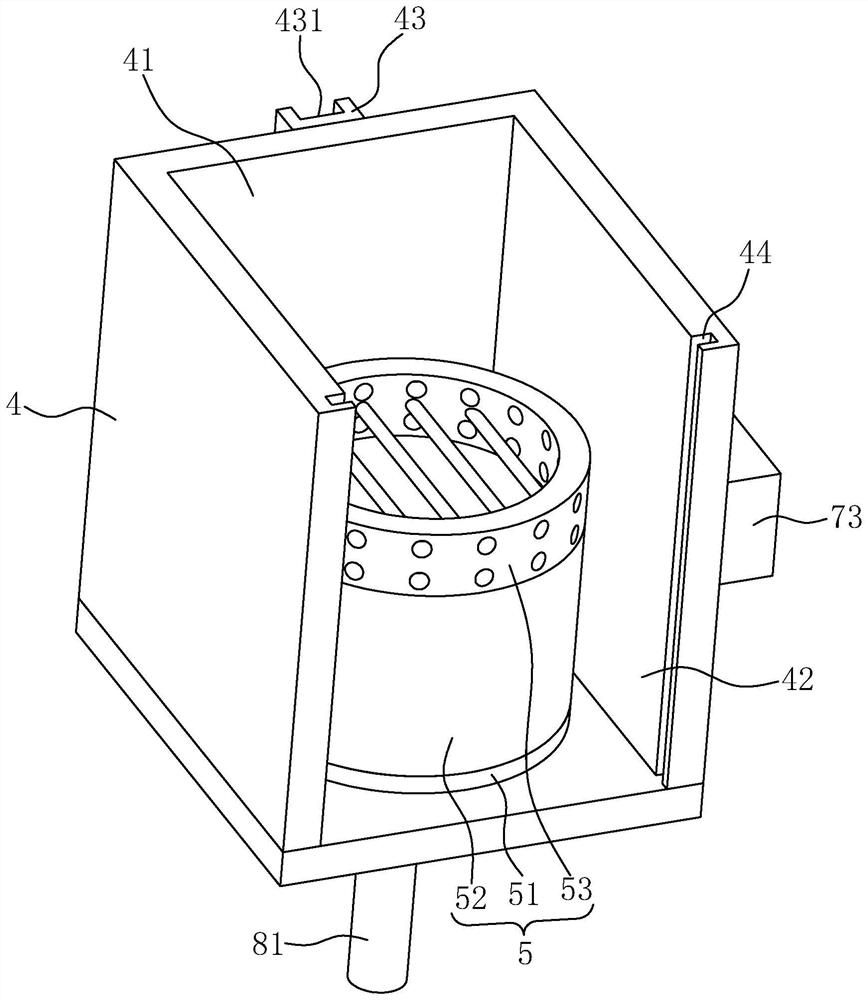

[0039] refer to figure 2 and image 3 The rotating box 2 is vertically slidably connected with a lifting box 4, the top of the lifting box 4 has a discharge port 41, and the side of the lifting box 4 facing the air inlet 22 has an air inlet 42, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap