Jumper wire adaptive positioning device capable of realizing rapid disassembly and assembly

A positioning device, jumper wire technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problem of inability to perform accurate and fast welding due to infinite characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The principles and features of the present invention will be described below with reference to the accompanying drawings, and the exemplary examples are intended to be construed as not intended to limit the scope of the invention.

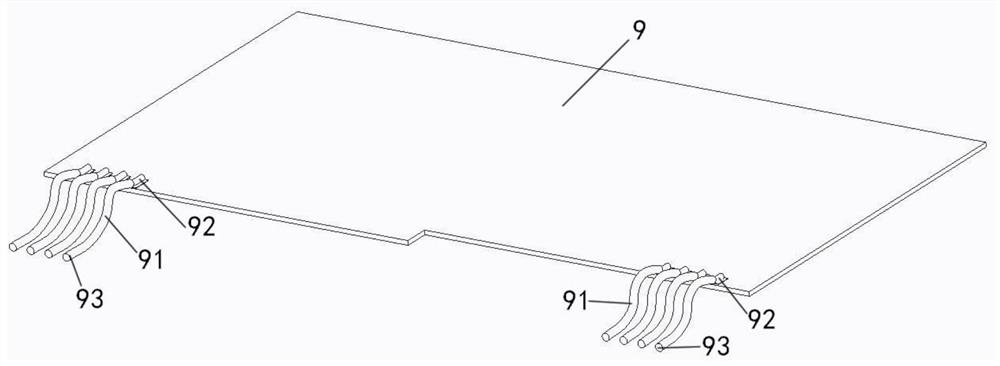

[0051] Such as Figure 8 As shown, the printed plate is mounted in the printed plate assembly frame 24 as the center of the jumper 91 as the center of the bridge, and the front end of the placement position of the bridge 91, the printed plate assembly hollow 21 side as a bridge wire 91 The rear end of the placed, both the cross wire 91 are arranged around the printed plate, so that the cross-wiring 91 is placed across the wire 91 in the printed plate assembled, so that the front end 92 of the cross-wiring 91 is close to the printing. The panel assembles the direction of the hollow 21 extends, so that the wire rear end 93 of the cross wire 91 is arranged in a direction away from the printed plate to assemble the hollow 21.

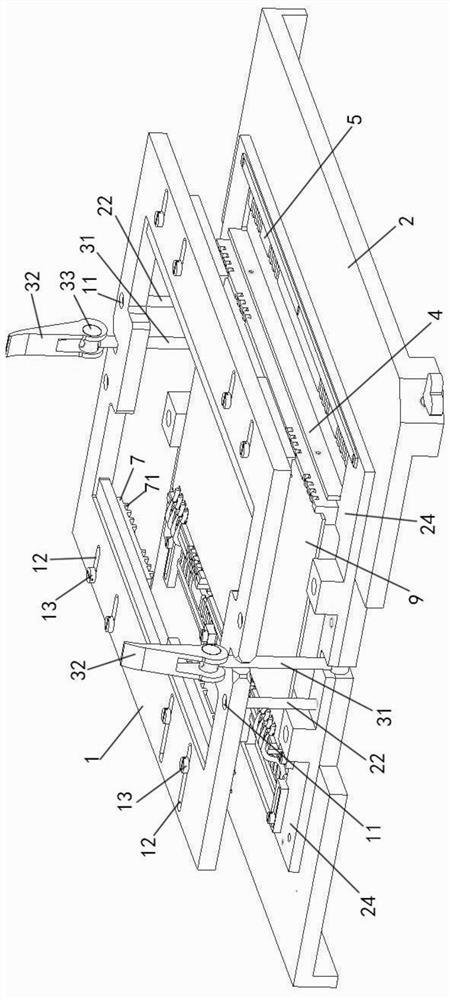

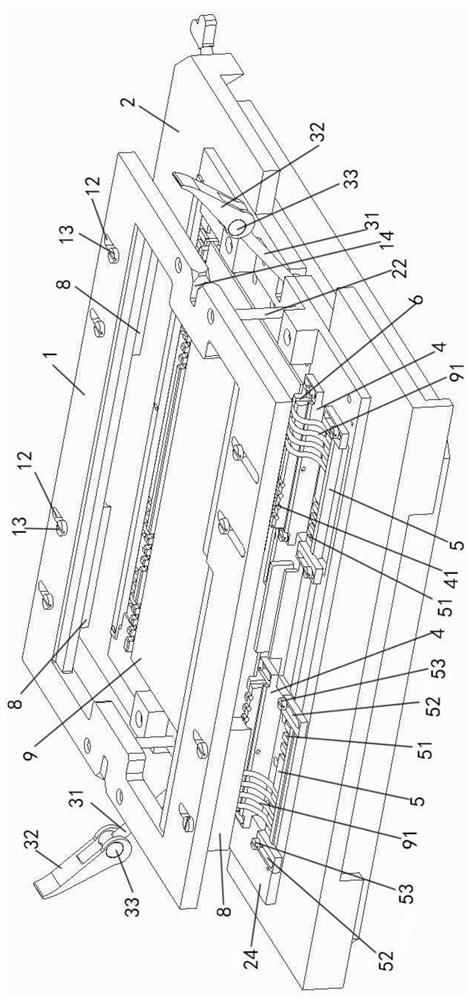

[0052] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com