Biaxial stretching device for film production

A biaxial stretching and film technology, applied in the field of biaxial stretching devices for film production, can solve the problems of unfavorable production, cumbersome operation steps, time-consuming and labor-intensive, etc., and achieve the effect of winding and tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

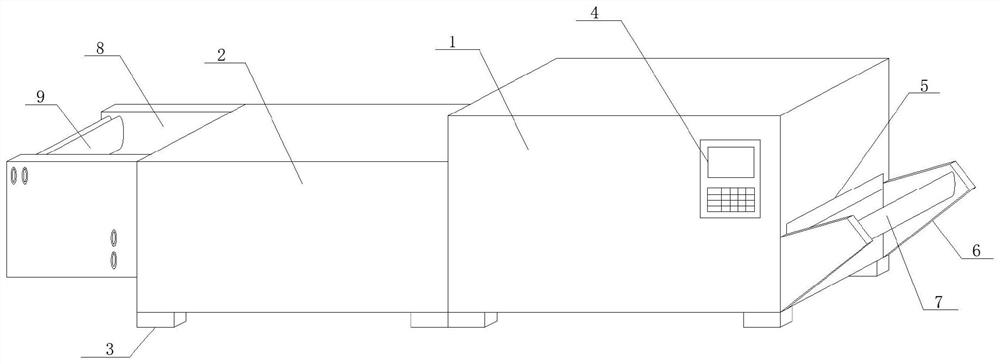

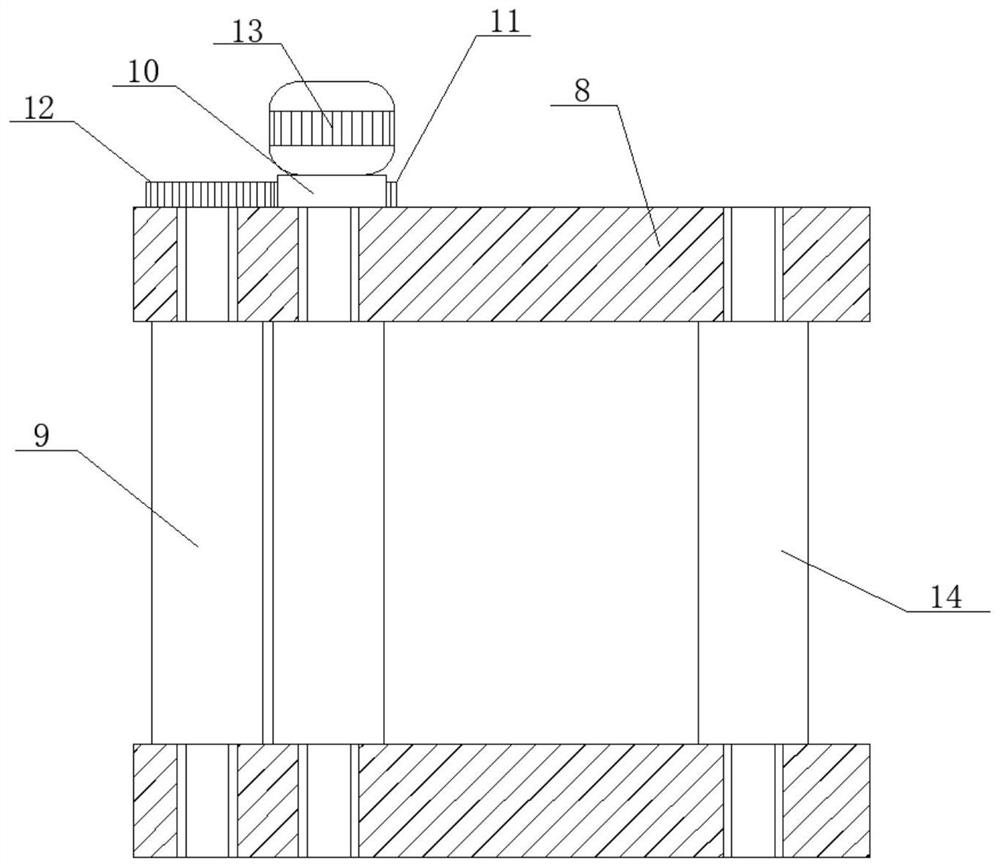

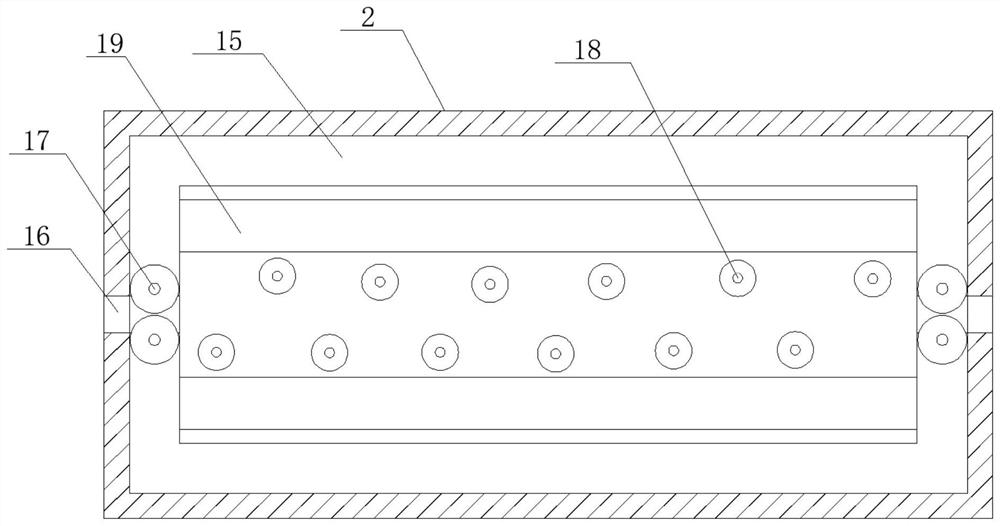

[0028] see Figure 1-2, in an embodiment of the present invention, a biaxial stretching device for film production includes a processing main box 1, an extension box body 2 is connected to one side of the processing main box 1 by bolts, and the bottom surface of the processing main box 1 and the extension box body 2 A support bottom block 3 is welded, a control panel 4 is inlaid on one side of the processing main box 1, and a connection groove 5 is opened horizontally and symmetrically on both sides of the processing main box 1, and the bottom surface of the extension box body 2 is connected to the bottom surface of the processing main box 1. The bottom surface is kept at the same horizontal plane position, the number of supporting bottom blocks 3 is multi-block, and the multi-block supporting bottom blocks 3 are all fixedly arranged on the bottom surface of the processing main box 1 and the extension box body 2 near the edge position, and the connecting groove 5 is opened The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com