Coconut shell sculpture forming process

A molding process, coconut shell technology, applied in the field of coconut shell sculpture molding technology, can solve the problems of not being three-dimensional enough, and achieve the effect of wide practicability, modern and simple shape, and full of changes in size and form of works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention is a kind of coconut shell sculpture molding process, comprises the following steps:

[0024] Step 1: Select a number of natural coconut shell blanks, rough process the coconut shell blanks, and remove the coconut palm on the surface. The larger the size and the thicker the thickness, the larger the shape can be made;

[0025] Step 2: Draw several polygons on the surface of the coconut shell according to the size of the coconut shell, and then cut the coconut shell into several three-dimensional geometric shapes with neat edges according to the drawn polygons;

[0026] Step 3: Splicing the coconut shells cut in step 2 to form a variety of different three-dimensional coconut shell shapes;

[0027] Step 4: Use an adhesive to stick the spliced coconut shells together to fill the gaps between the coconut shells and make the coconut shells more three-dimensional;

[0028] Step 5: Cut out other polygons according to the size of the coconut shell edge ...

Embodiment 2

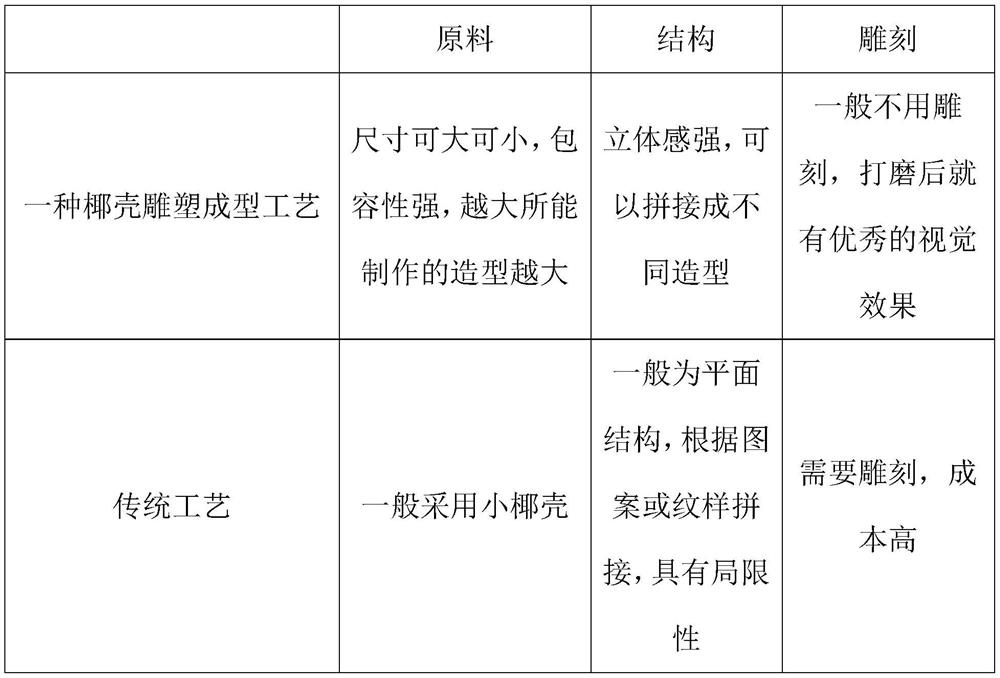

[0038] The present invention is a coconut shell sculpture molding process, which has the following improvements compared with the traditional coconut shell process, see the following table for details:

[0039]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap