Heavy transport vehicle chassis with high trafficability

A transport vehicle and chassis technology, which is applied in the field of vehicle engineering, can solve the problems of large frame disturbance and stress, increased load capacity, and difficult operation, etc., to achieve lightweight, optimized force conditions, and small steering angle errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

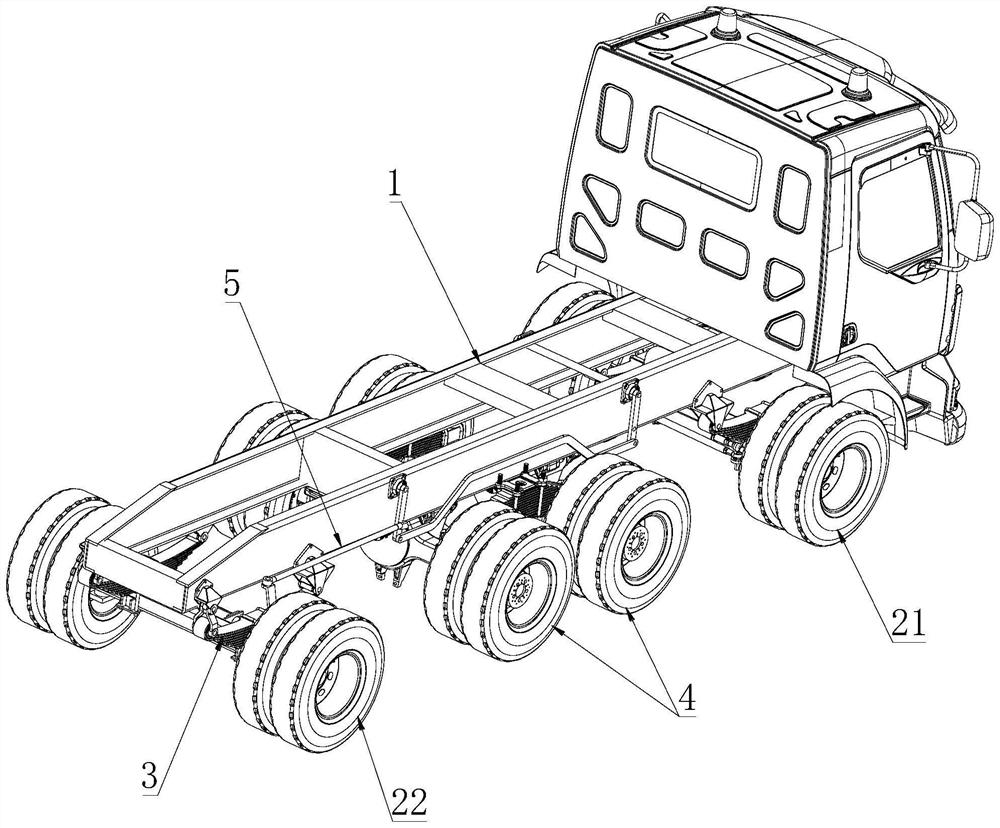

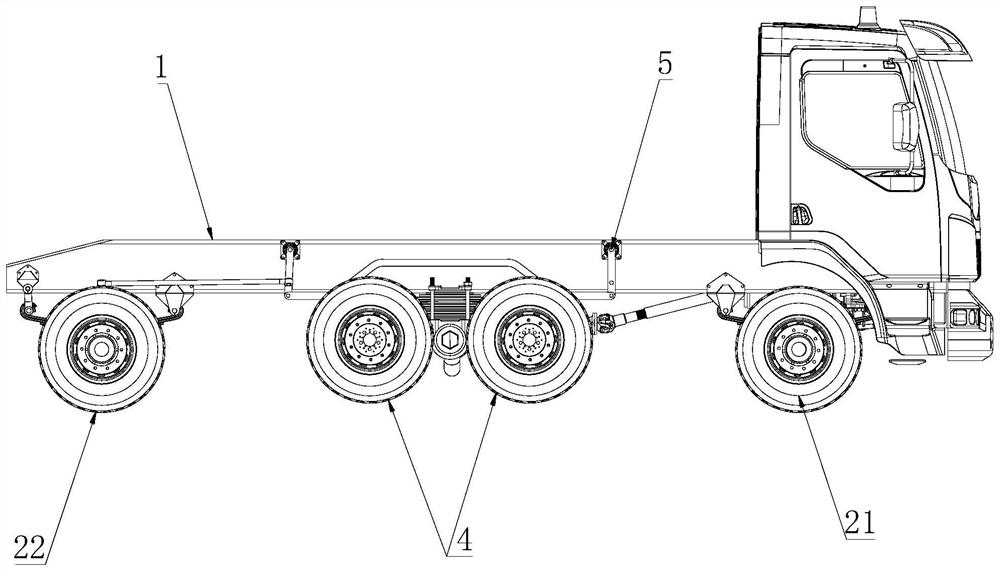

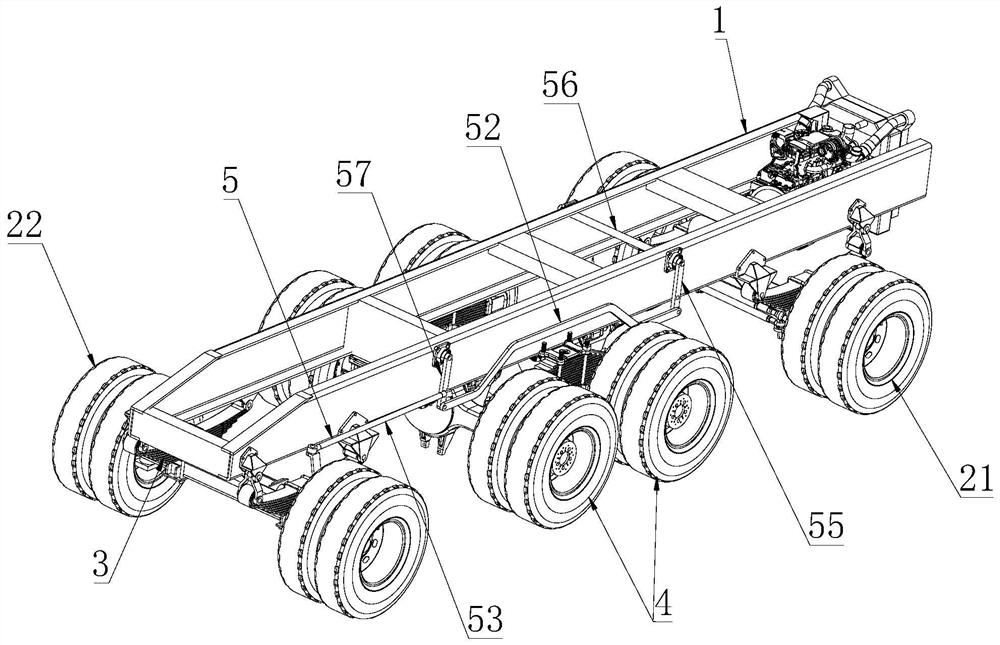

Image

Examples

Embodiment Construction

[0051] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0052]The inventors of the present application have found that the existing heavy-duty transportation vehicle chassis is usually a riveted structure or a welded structure, resulting in a large transmission impact during the transmission of the current heavy-duty transportation vehicle chassis. Due to the long overall length, it is also difficult to turn around. During the steering operation, the two-wheel steering structure of the heavy-duty transport vehicle leads to a large turning radius. When driving in the mountains and construction sites, it encounters a narrow road surface, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com