Maintenance device and method for bridge mass concrete foundation

A technology of mass concrete and concrete foundation, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as large temperature difference, and achieve the effect of reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

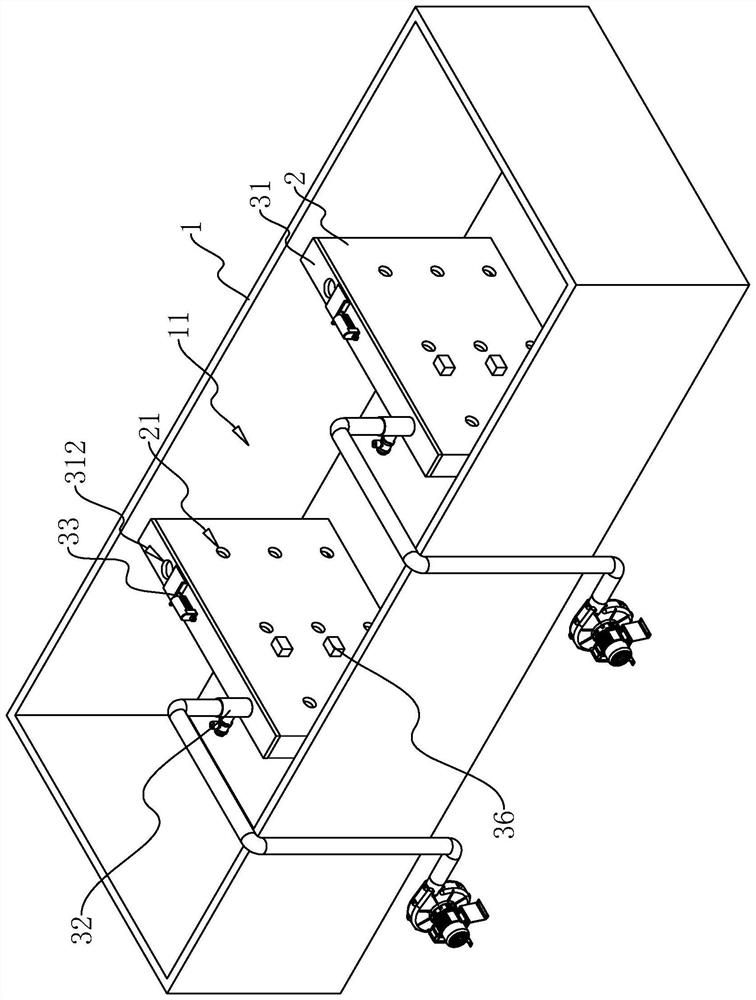

[0048] The embodiment of the application discloses a maintenance device for a large-volume concrete foundation of a bridge. refer to figure 1 The maintenance device for the mass concrete foundation of the bridge includes a main body forming formwork 1 and a plurality of inner ring formwork units 2 located in the main body forming formwork 1 . Both the main body forming formwork 1 and the inner ring formwork unit 2 are in the shape of a square frame. In other embodiments, the main body forming formwork 1 can also be in the shape of a cylinder according to the shape requirements of the concrete foundation. The four side walls of the main body forming formwork 1 can be made of multiple Made of steel plates.

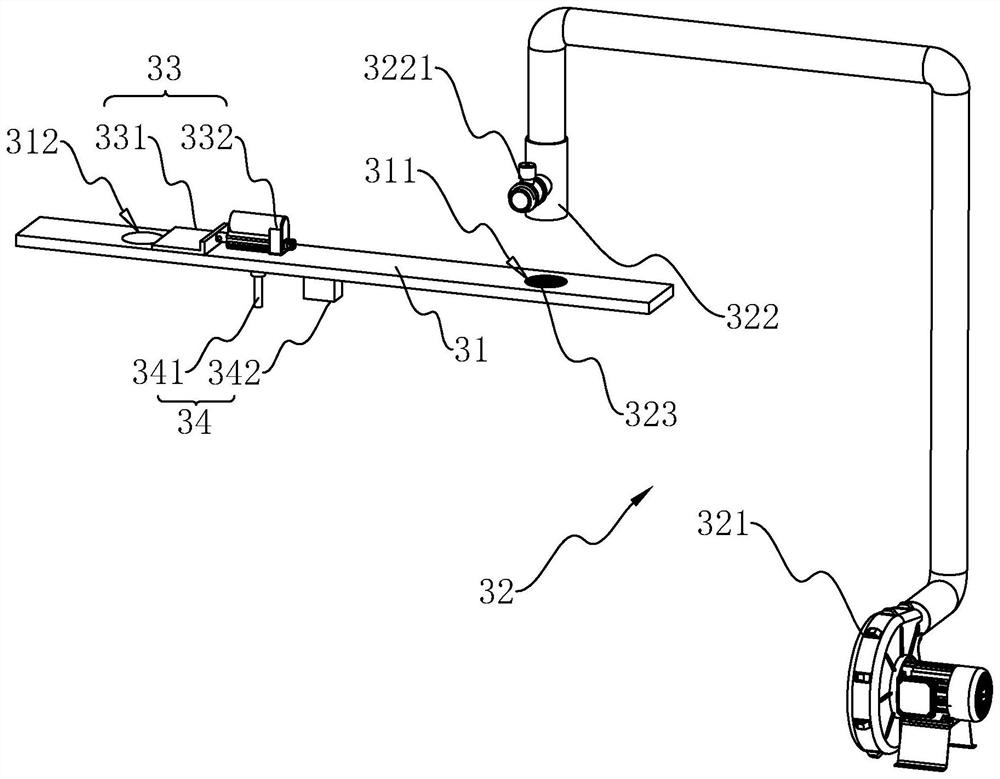

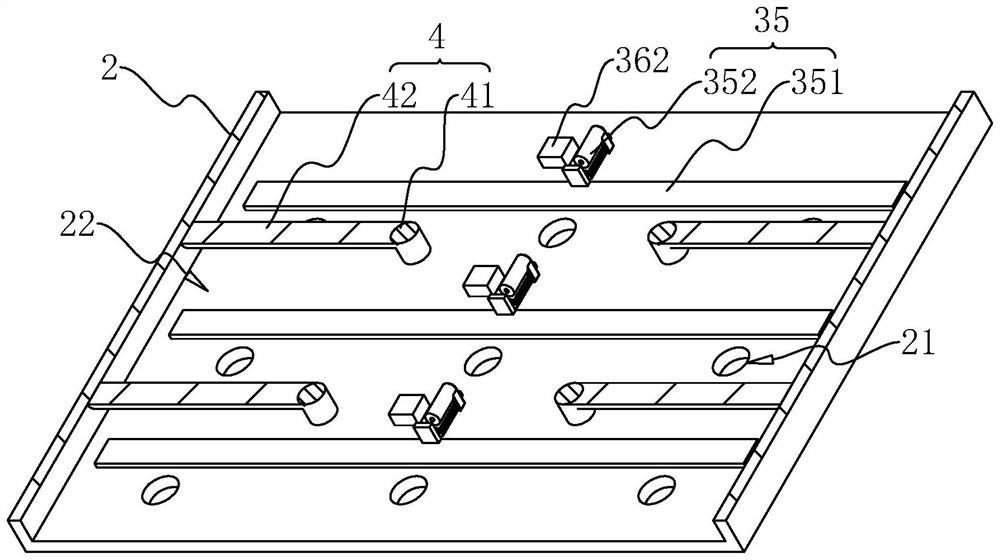

[0049] refer to figure 2 and image 3 , two inner ring template units 2 are provided, and the two inner ring template units 2 are arranged at intervals along the length direction of the main body forming template 1 . The inner wall of the main body forming formwork 1 an...

Embodiment 2

[0071] refer to Figure 6 and Figure 7 The difference between the second embodiment of the present application and the first embodiment is that the moisture in the concrete foundation will be lost during the opening process of the curing hole 21 , and the inner ring formwork unit 2 is provided with a humidity adjustment mechanism 5 .

[0072] refer to Figure 7 and Figure 8 The humidity adjustment mechanism 5 includes a water delivery pipe 51 connected to the inner wall of the inner ring formwork unit 2, a plurality of compressed air pipes 52 bound on the water delivery pipe 51, a plurality of nozzles 53 connected to the water delivery pipe 51 and used to control each The spray head 53 is a water spray control assembly 54 for spraying water, and the pinch plate 31 is provided with a through hole through which the water delivery pipe 51 passes. The nozzles 53 correspond to the maintenance holes 21 one by one, and the water outlets of the nozzles 53 face the maintenance hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com