Support for positioning reinforcement cage segments

A steel cage and segment technology, which is used in the erection/assembly of bridges, bridge parts, sheet pile walls, etc., can solve the problems of difficult connection and alignment of steel cage segments, disturbance and deformation of steel bars, etc. Integrity and stiffness, the effect of convenient hand-held operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

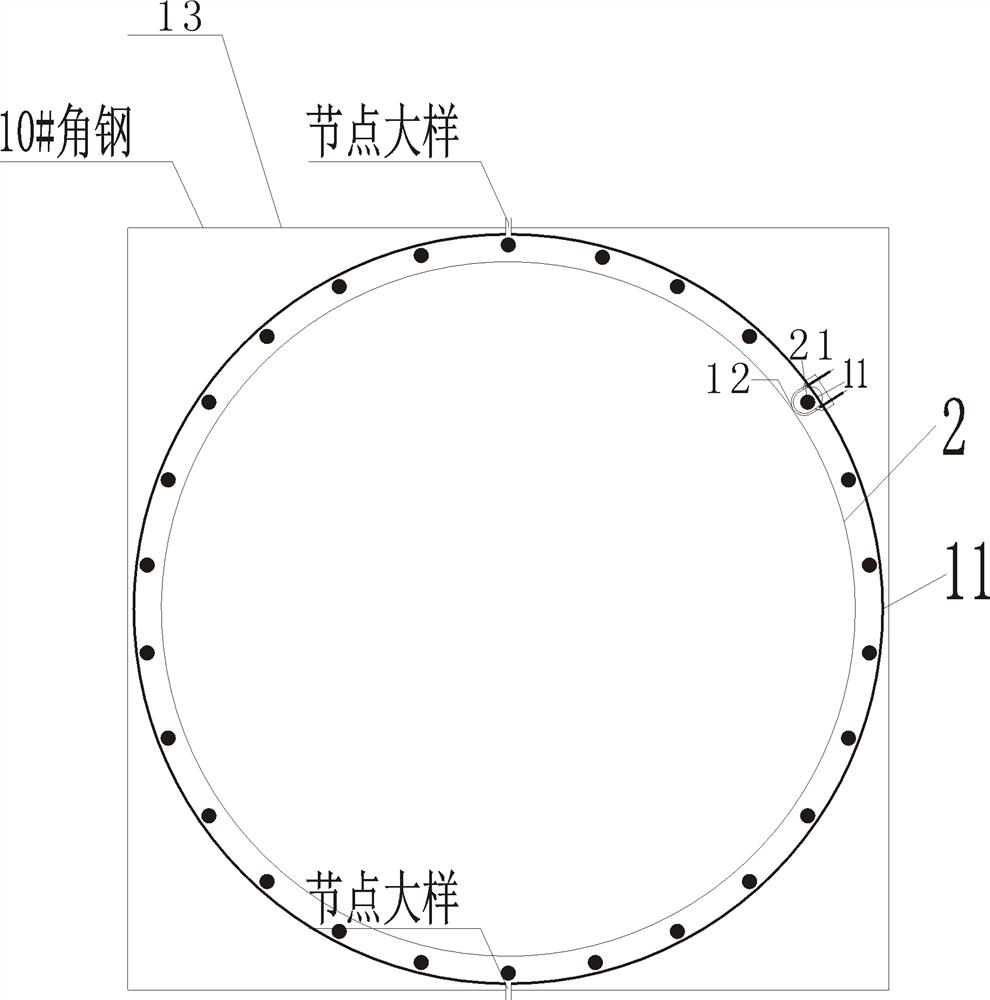

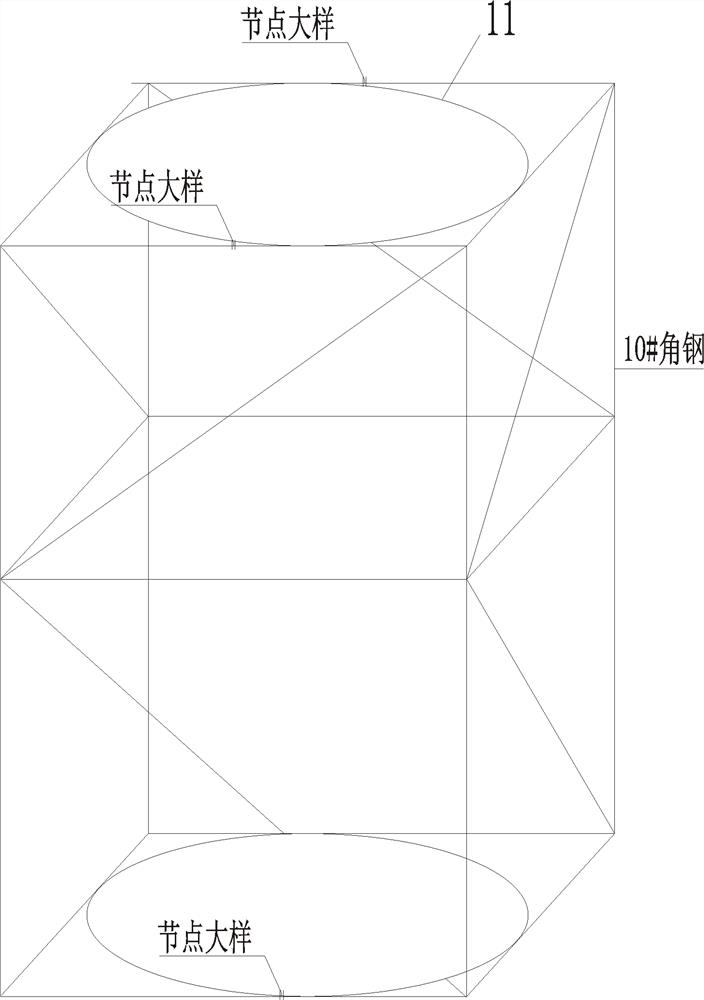

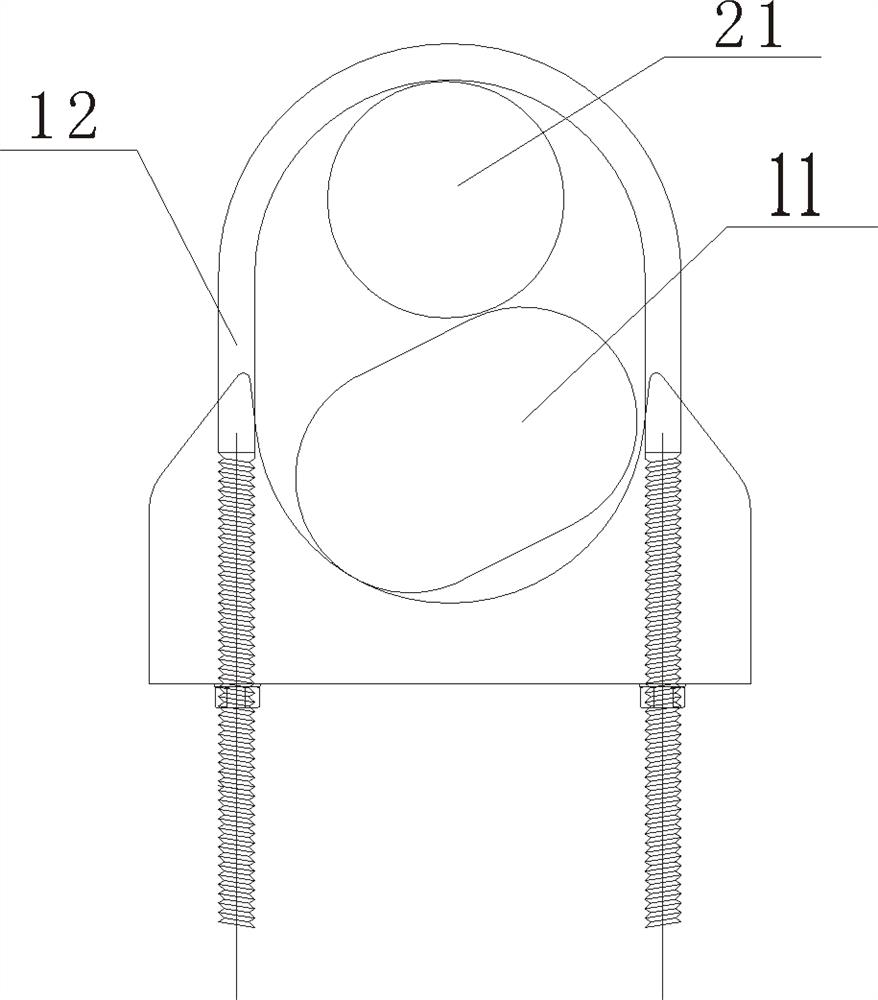

[0032] Embodiment 1: A bracket for positioning steel cage segments, as shown in the figure, includes a ring piece 11, the ring piece 11 is a split structure, and the ring piece 11 includes at least two sections of arc-shaped units, which are convenient for installation and disassembly; The member 11 is provided with positioning members 12 at intervals in the circumferential direction, and the positioning members 12 are used for detachably connecting each longitudinal steel bar 21 in the reinforcement cage.

[0033] The support for segmental positioning of the reinforcement cage provided in this embodiment is the size of the ring member determined according to the circumference of the reinforcement cage to be positioned, and the positioning member on the ring member is set according to the number of longitudinal reinforcement bars on the reinforcement cage and the preset spacing. Quantity and position, so that the ring parts can be set on the inside or outside of the steel cage,...

Embodiment 2

[0046] Embodiment 2: Based on the above embodiment, the above-mentioned ring member can be arranged as an integrally formed structure, which can be arranged inside or outside the reinforcement cage. During the production of the reinforcement cage, the end of the longitudinal reinforcement is directly bound through the ring piece and the positioning piece at the corresponding position, and the reinforcement cage is formed; When there is no disturbing deformation in the process or the disturbing deformation is small enough, the ring piece is pulled out from the connecting end of the steel cage, and it is docked with the steel cage segment that also ensures that the longitudinal steel bar is in place, so as to solve the problem of longitudinal steel bar misalignment and deformation. Alternatively, the ring is placed inside the reinforcement cage and poured together with the reinforcement cage.

[0047] Reinforcement cage installation process (such as Figure 7-Figure 8 ): (1) Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com