Waterproof glass fiber tile mounting device

A technology of waterproof fiberglass tiles and installation devices, which is applied to tools used in roofing engineering, roofing, construction, etc., can solve problems such as low efficiency, large manpower consumption, roof leakage, etc., and achieve the effect of easy laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

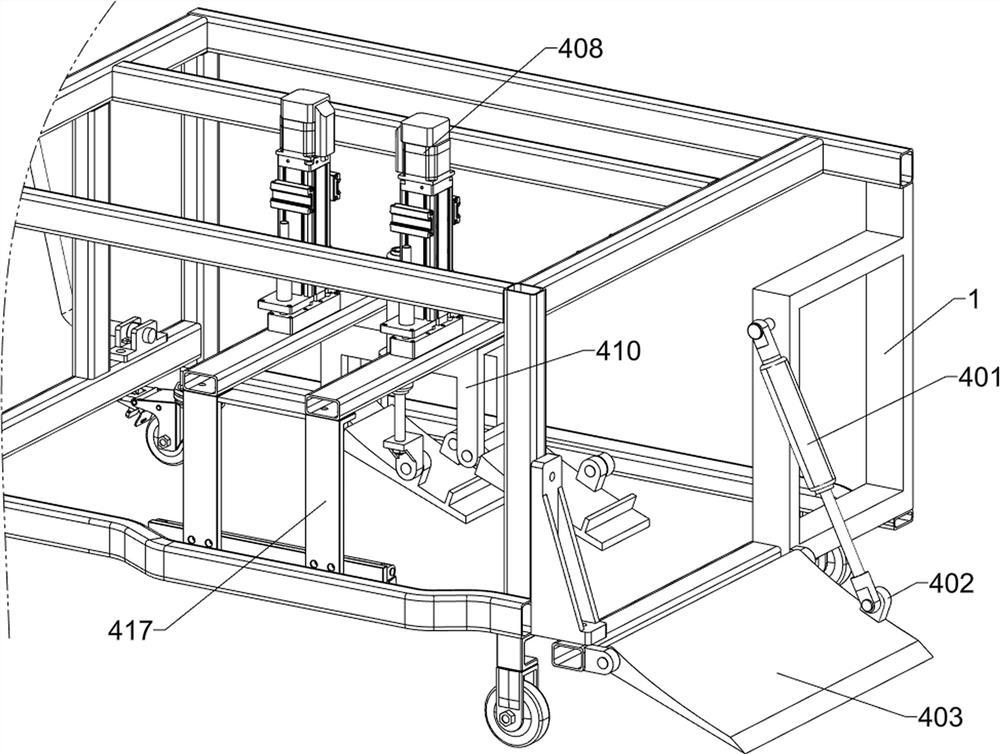

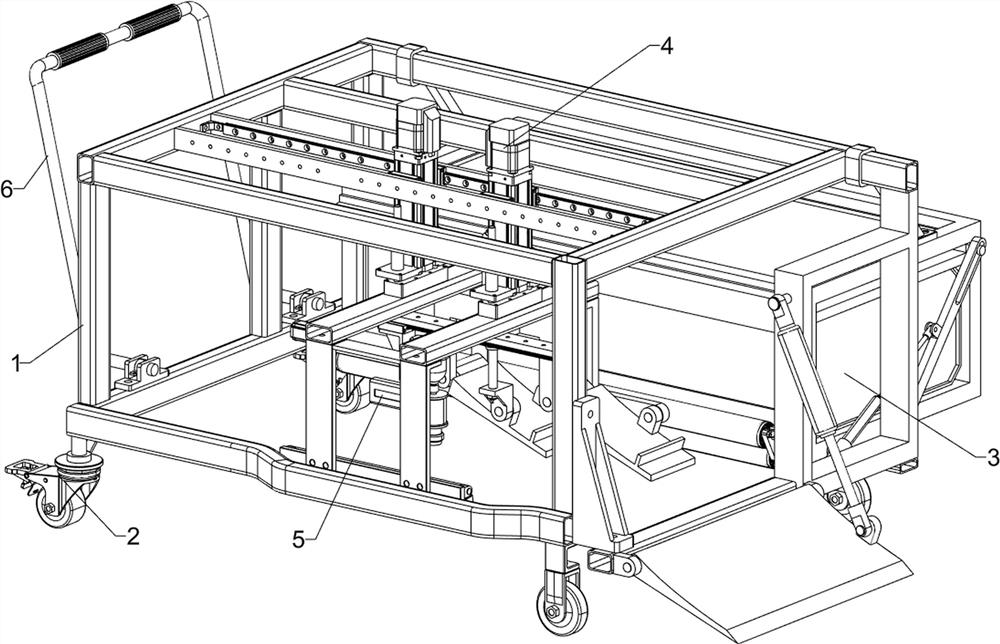

[0039] A waterproof glass fiber tile installation device, such as Figure 1-3 As shown, it includes a frame 1, wheels 2, a feeding system 3 and a laying system 4; each of the four corners of the lower surface of the frame 1 is connected with a wheel 2; the rear of the frame 1 is connected with a feeding system 3; the frame 1 A laying system 4 is connected inside; a handrail 6 is connected to the left part of the frame 1 .

[0040] Working principle: When using the waterproof fiberglass tile installation device, first place the waterproof fiberglass tile installation device on the roof where waterproof fiberglass tiles need to be laid, and then the operator puts the waterproof fiberglass tile into the feeding system 3, and then connects Turn on the built-in power supply, and then the operator pushes the waterproof glass fiber tile installation device to the corner of the roof, lays the waterproof glass fiber tile from the corner to the middle, and then controls the feeding syst...

Embodiment 2

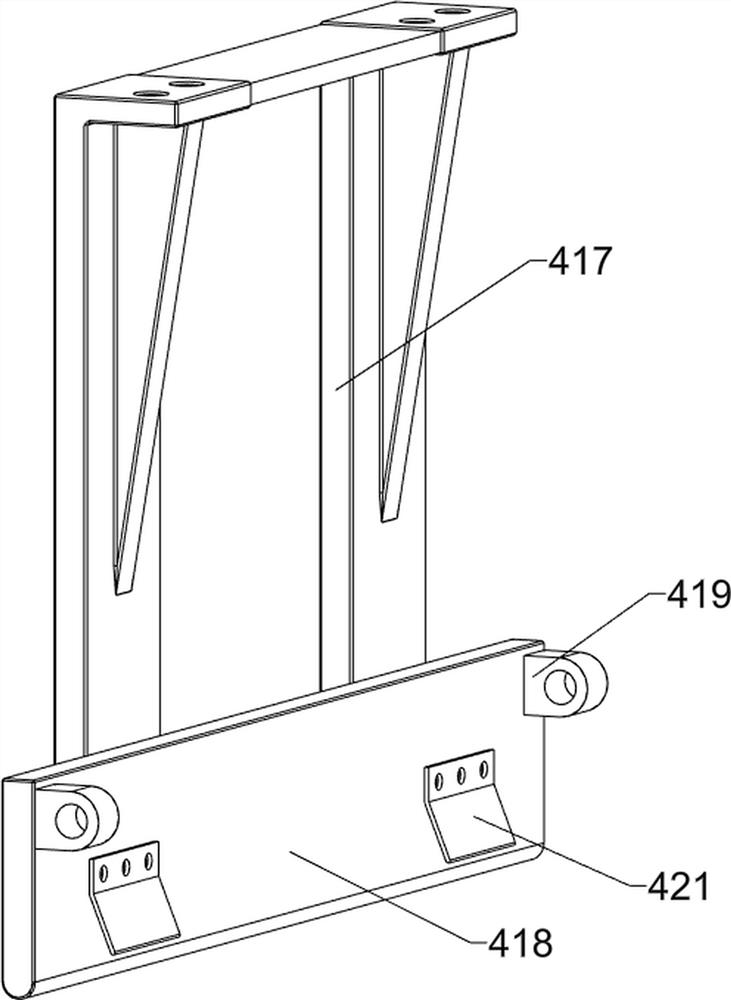

[0042] On the basis of Example 1, such as figure 1 and Figure 4-16 As shown, the feeding system 3 includes a placement bin 301, a bracket 302, a connecting sleeve 303, a first electric push rod 304, a transmission rod 305, a first connecting seat 306, a toggle plate 307, a first guide plate 308, a second Guide plate 309, second connecting seat 310, first rotating roller 311, second rotating roller 312, first spur gear 313, second spur gear 314, first connecting plate 315, motor 316, cabin door 317, handle 318, First elastic part 319 and stage 320; Frame 1 rear portion is fixedly connected with placement bin 301; Place bin 301 upper surface right and upper surface left each bolt is connected with a bracket 302; Two brackets 302 and frame 1 phase connection; the outer right side and the outer left side of the storage compartment 301 are respectively connected with a connecting sleeve 303 through a rotating shaft; each of the two connecting sleeves 303 is fixedly connected with...

Embodiment 3

[0056] On the basis of Example 2, such as figure 1 and Figure 17 As shown, it also includes a fixing system 5; the lower surface of the two third connecting plates 409 is connected with the fixing system 5; the fixing system 5 includes a sixth connecting plate 501, a second electric slide rail 502, a second electric slider 503, The third connecting frame 504 and the pneumatic nail gun 505; the middle part of the lower surface of the two third connecting plates 409 is fixedly connected with the sixth connecting plate 501; the lower surface of the sixth connecting plate 501 is fixedly connected with the second electric slide rail 502; The outer surface of the slide rail 502 is slidably connected with a second electric slider 503; the lower surface of the second electric slider 503 is fixedly connected with a third connecting frame 504; the right part of the third connecting frame 504 is fixedly connected with a pneumatic nail gun 505.

[0057] Working principle: When two water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com