Manufacturing process method of plastic water level strip, plastic water level strip and injection mold

A manufacturing process and injection molding technology, which is applied in the field of smart household daily necessities production, can solve the problems of deformation of plastic sleeves, failure to obtain sealing effect, low yield of plastic water level strips, etc., and achieve the effect of solving sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

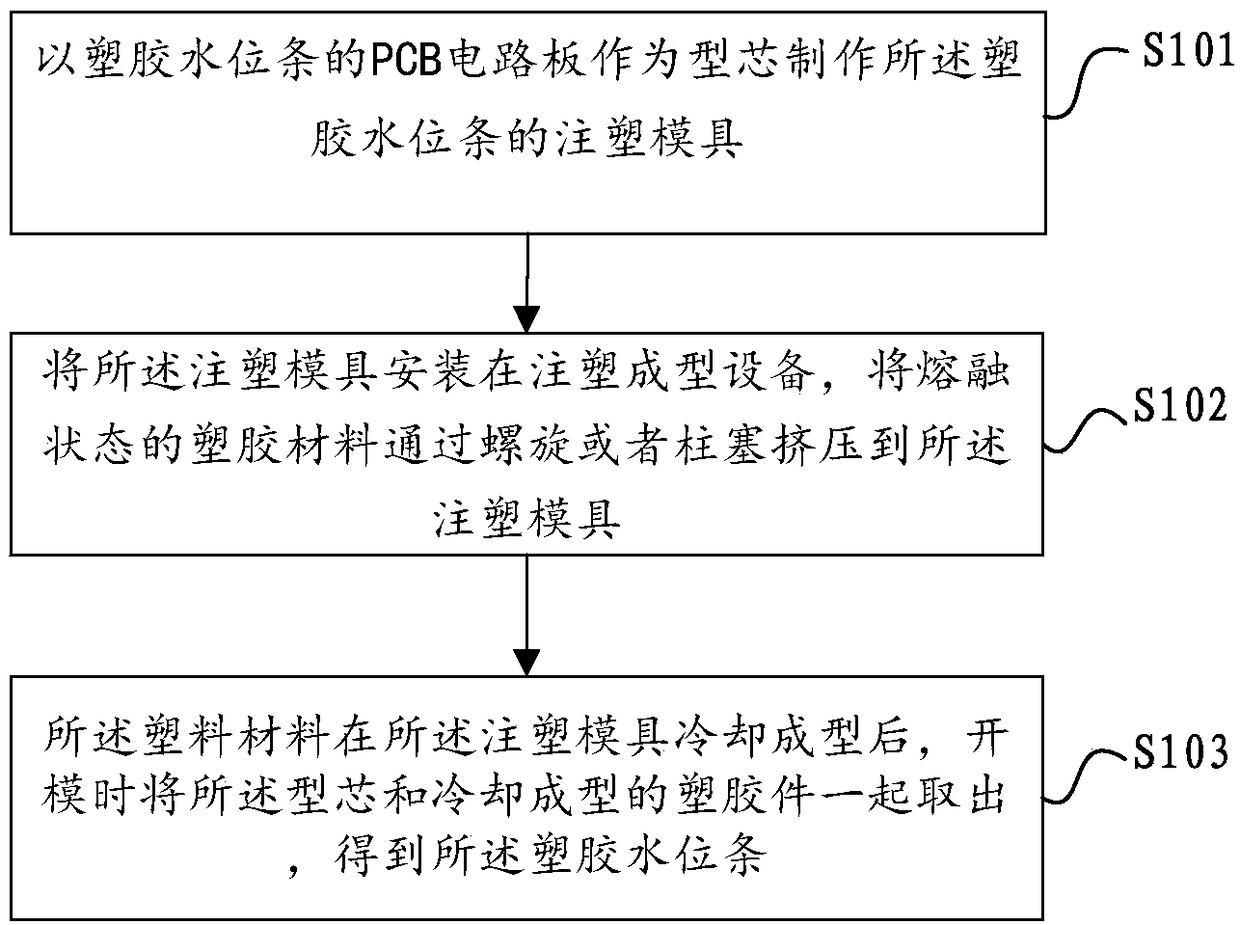

[0043] Such as figure 1 As shown, the present invention provides a method for manufacturing a plastic water level bar, the method comprising the following steps:

[0044] S101, using the PCB circuit board of the plastic water level strip as the core to make an injection mold for the plastic water level strip;

[0045]S102. Install the injection mold on the injection molding equipment, and extrude the molten plastic material into the injection mold through a screw or a plunger;

[0046] Optionally, the plastic material is any one of food grade PP, PETG, PCTG, PCTA and PPSU.

[0047] Wherein, the installation of the injection mold on the injection molding equipment, and extruding the plastic material in the molten state to the injection mold through a screw or a plunger includes:

[0048] Select the type of injection molding equipment according to the plastic material, and set injection molding parameters including barrel temperature, nozzle temperature, melt temperature, mold...

Embodiment 2

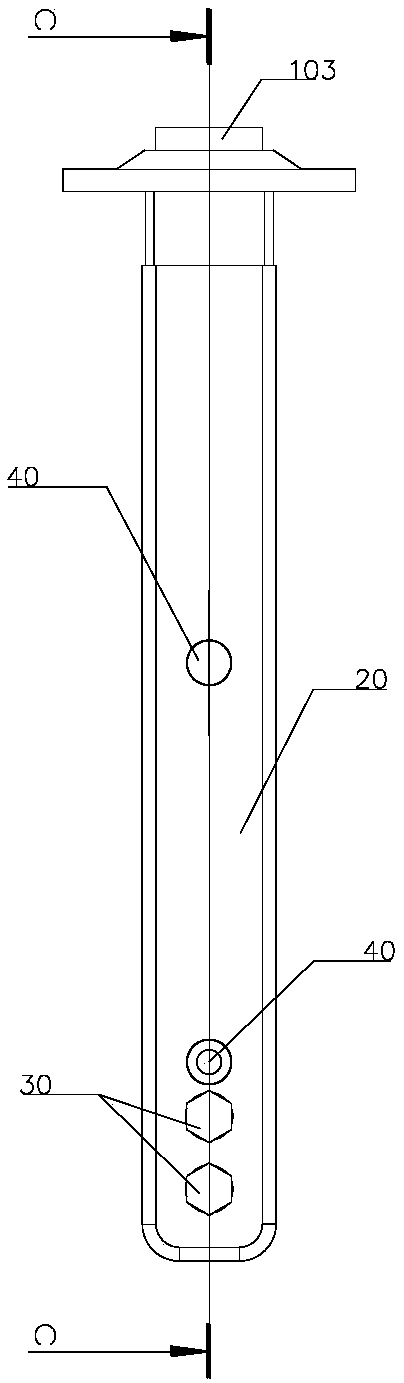

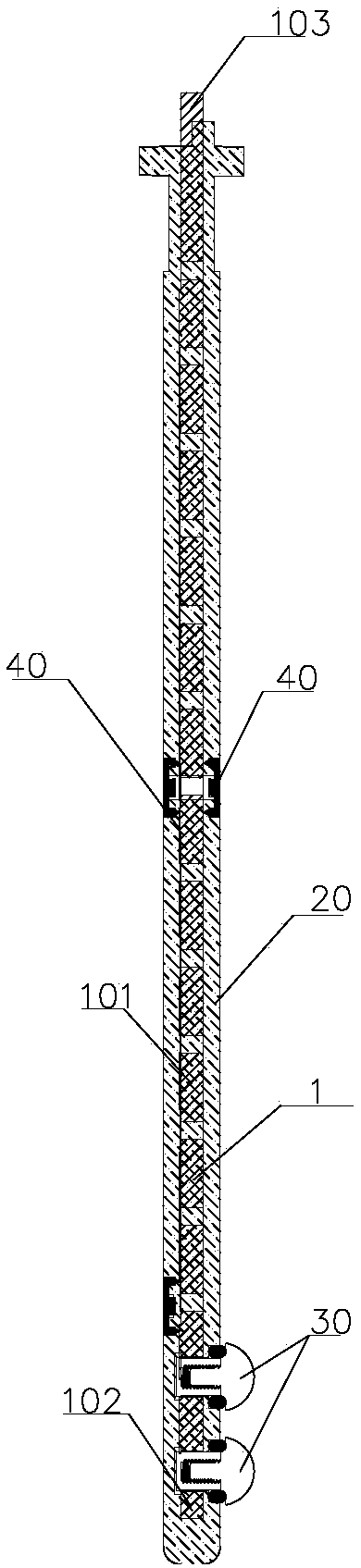

[0099] Based on the same inventive concept, another aspect of the present invention provides a plastic water level bar, which is realized by using the above-mentioned manufacturing process of the plastic water level bar, such as figure 2 , 3, 4, the plastic water level bar includes: a PCB circuit board 1 and a plastic part 20 integrally formed on the PCB circuit board 1, and one side of the PCB circuit board 1 is evenly spaced and provided with a plurality of The sensing electrode 101 for water level detection, the lower end of the PCB circuit board 1 is provided with a group of TDS measuring electrodes 30 for TDS water quality detection; the TDS measuring electrodes 30 pass through the plastic part 20; the PCB circuit board 1 The upper end is provided with a circuit interface 103 ; the circuit interface 103 passes through the plastic part 20 .

[0100] Wherein, the plastic part 20 forms a waterproof protective layer with a thickness of 1-1.5 mm on the PCB circuit board 1 . ...

Embodiment 3

[0108] Based on the same inventive concept, another aspect of the present invention provides an injection mold, utilizing the above-mentioned plastic water level bar manufacturing process method, such as Figure 7 As shown, the injection mold includes: a sizing plate 4, a fixed mold base plate 5, a movable mold base plate 9, a PCB circuit board 1 and a group of Huff blocks 3, with the PCB circuit board 1 as a core, the The circuit interface of the PCB circuit board 1 is installed on the movable mold seat plate 9 through a core fixing plate 10, and is positioned by a plurality of core fixing screws 8 passing through the Huff block 3, and the PCB circuit board 1 and A group of said half blocks 3 form the mold cavity of plastic parts, said half blocks 3 are installed in said fixed mold base plate 5 through dovetail guide bars 6, and said fixed mold base plate 5 is provided with a setting plate at the center of the upper end 4. The sizing plate 4 is provided with a gate 41 and a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com