Balanced aerodynamic force type breather valve and working method

A pneumatic and breathing valve technology, applied in the direction of balance valve, multi-way valve, safety valve, etc., can solve the problems of left and right vibration of the valve disc, frequent take-off, large opening and closing pressure difference, etc., to reduce the closing pressure and speed of response Fast and reduce the effect of closing pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

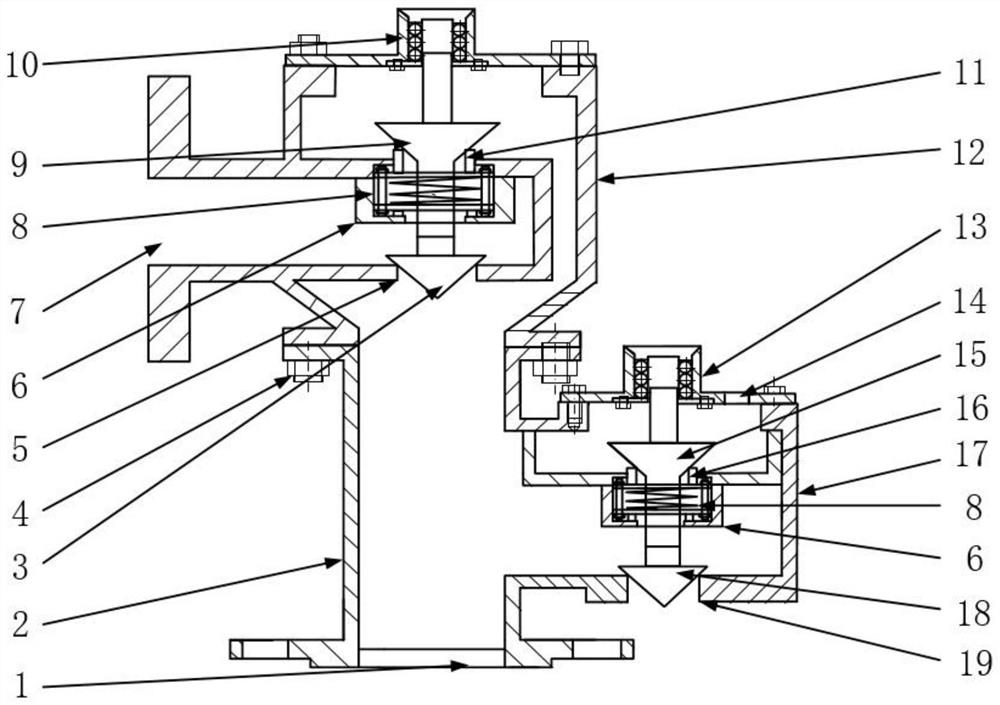

[0049] According to the specific form and working principle of the mechanical structure of the balanced pneumatic breathing valve safety device, the implementation points of its assembly method are as follows:

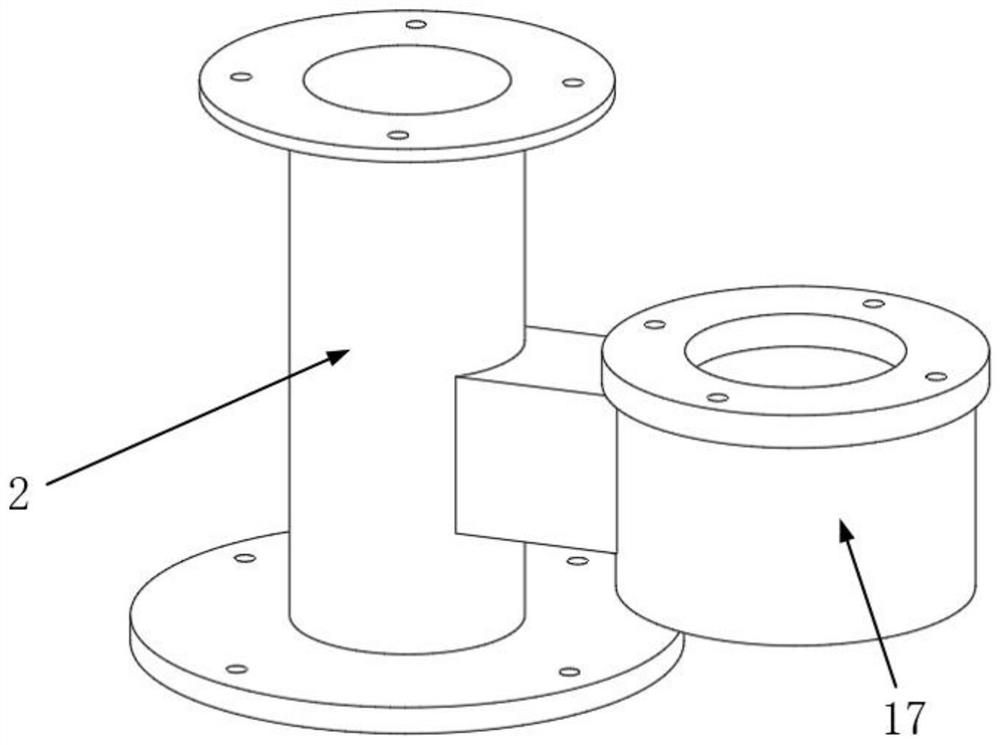

[0050] a) The valve body 2 communicates with the external air source through the air inlet hole 1;

[0051] Above, the lower end 3 of the call valve cone valve disc is threadedly connected with the upper end 9 of the call valve cone valve disc through the external thread 20 at the upper end of the call valve cone valve disc and the inner thread 21 at the lower end of the call valve cone valve disc;

[0052] b) The upper end 9 of the call valve cone valve disc is placed above the discharge port 11 at the upper end of the call valve, and the outer surface of the upper stem of the call valve cone valve disc upper end 9 is closely attached to the raised interior of the call valve bearing bonnet 10 The inner surface of the exhalation valve bearing 24; exhalation valve shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com