Cold patch for drainage asphalt pavement and preparation method thereof

A technology of drainage asphalt and cold patching material, which is applied in the field of emergency maintenance and daily maintenance of asphalt pavement, and can solve the problems of drainage, anti-skid, noise reduction and other problems that cannot meet the requirements of drainage asphalt pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 A kind of cold patching material for drainage asphalt pavement

[0038] This embodiment provides a kind of cold patch material for drainage asphalt pavement, which consists of the following components by weight: 90 parts of aggregate, 9 parts of emulsified asphalt, and 5 parts of water-based polyurethane emulsion; wherein,

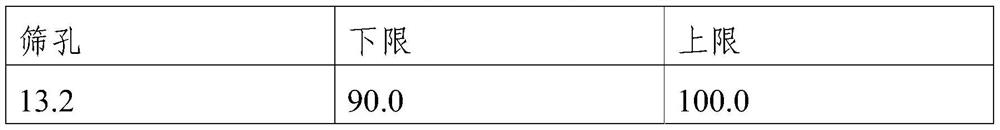

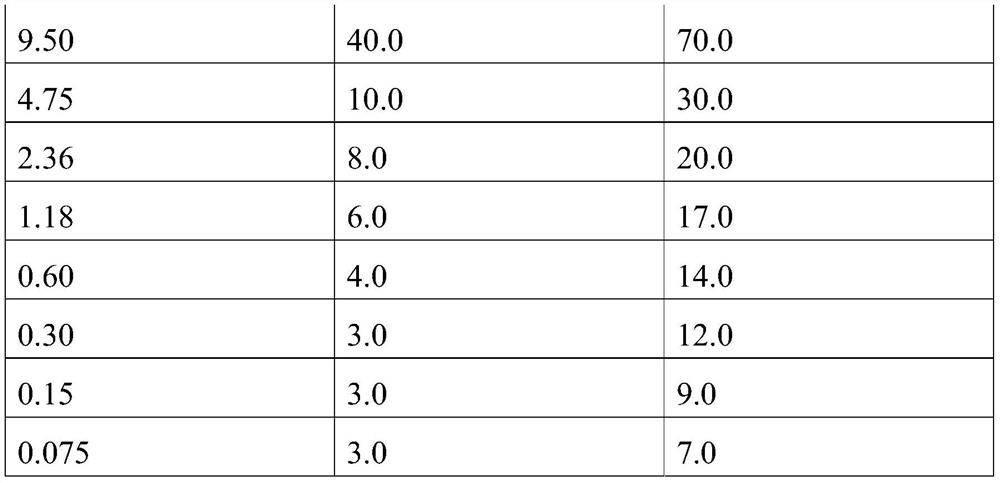

[0039] The aggregate is basalt and meets the requirements of Table 1 above.

[0040] Described emulsified asphalt adopts following method to make:

[0041] (1) Mix water and anionic emulsifier at a ratio of 40:1.8, stir at 55-65°C, and mix to obtain a uniform emulsion;

[0042] (2) Heating the asphalt to 120-160°C;

[0043] (3) Pour the heated asphalt into the obtained homogeneous emulsion for emulsification, and the emulsification time is 2 to 5 minutes to obtain final product;

[0044] Wherein, the weight ratio of the asphalt:water:emulsifier is 50:40:1.8.

[0045] The water-based polyurethane emulsion is an emulsion of water-base...

Embodiment 2

[0055] Embodiment 2 A kind of cold patching material for drainage asphalt pavement

[0056] This embodiment provides a cold patch for drainage asphalt pavement, which consists of the following components in parts by weight: 100 parts of aggregate, 15 parts of emulsified asphalt, and 5 parts of water-based epoxy resin emulsion. Proceed as follows:

[0057] (1) The aggregate is dried for subsequent use;

[0058] (2) Mix the water-based emulsion and emulsified asphalt, stir at a temperature of 20-40°C, the number of revolutions is 2500 / min, and the time is 3 minutes to obtain modified emulsified asphalt, which is ready for use;

[0059] (3) Add the modified emulsified asphalt to the aggregate, and mix it under the temperature condition of 20-40°C for 100-200s.

[0060] Wherein, the mixing described in step (3) can be by machine mixing or manual mixing.

Embodiment 3

[0061] Embodiment 3 A kind of preparation method of cold patching material for drainage asphalt pavement

[0062] The present embodiment provides a kind of preparation method of cold patching material for drainage asphalt pavement, comprising the following steps:

[0063] (1) The aggregate is dried for subsequent use;

[0064] (2) Mix the water-based emulsion and emulsified asphalt, and mix them at a temperature of 20-40°C for 3-15 minutes to obtain modified emulsified asphalt, which is ready for use;

[0065] (3) Add modified emulsified asphalt to the aggregate, and mix under the temperature condition of 20-40°C for 45-120s.

[0066] Wherein, the mixing described in step (3) can be by machine mixing or manual mixing.

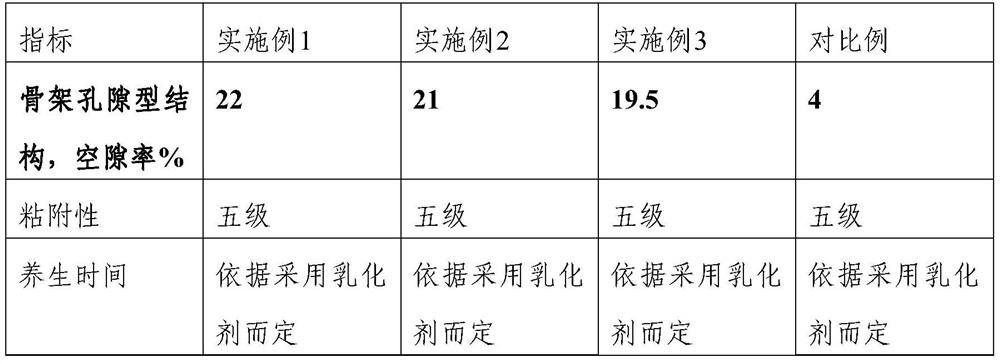

[0067] Effect verification

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com