Automatic integrated weighing device for finished magnesia and material control method thereof

A technology of weighing device and magnesia, which is applied in measuring device, weighing device for materials with special properties/forms, and weighing, etc., can solve the problems of cumbersome operation, affecting the progress of production process, and low proportioning accuracy. , to achieve the effect of improving metering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

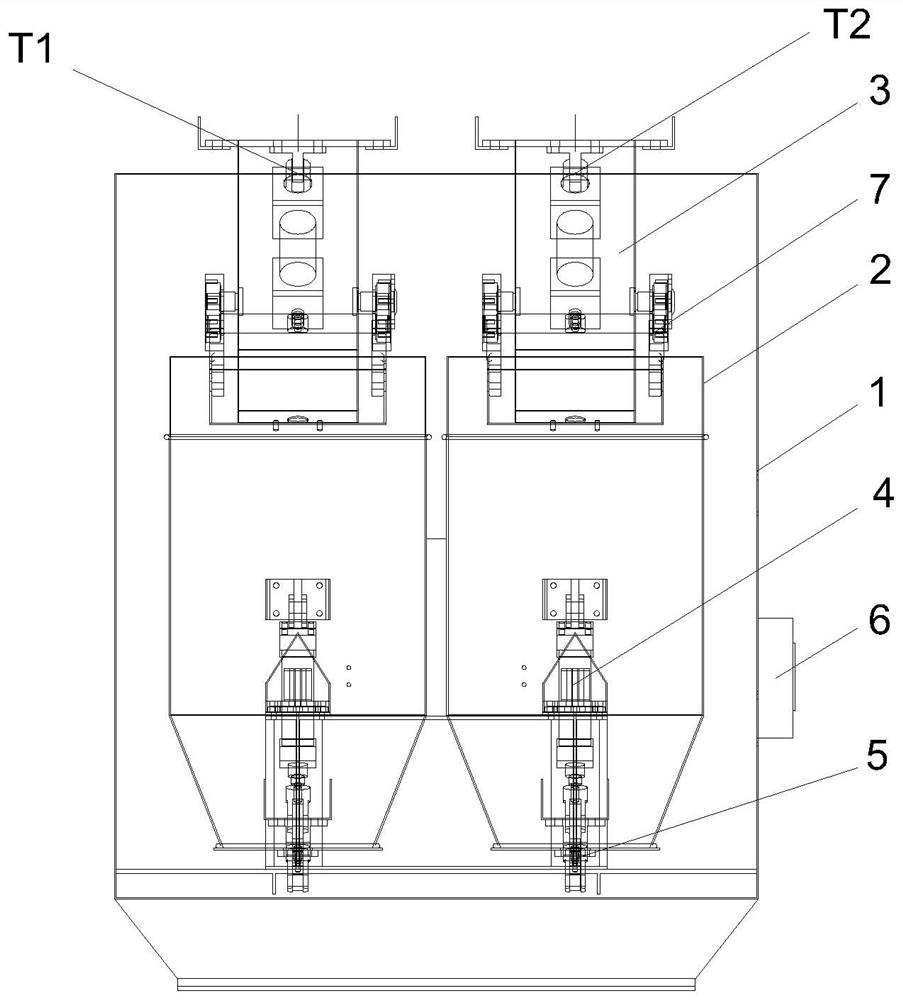

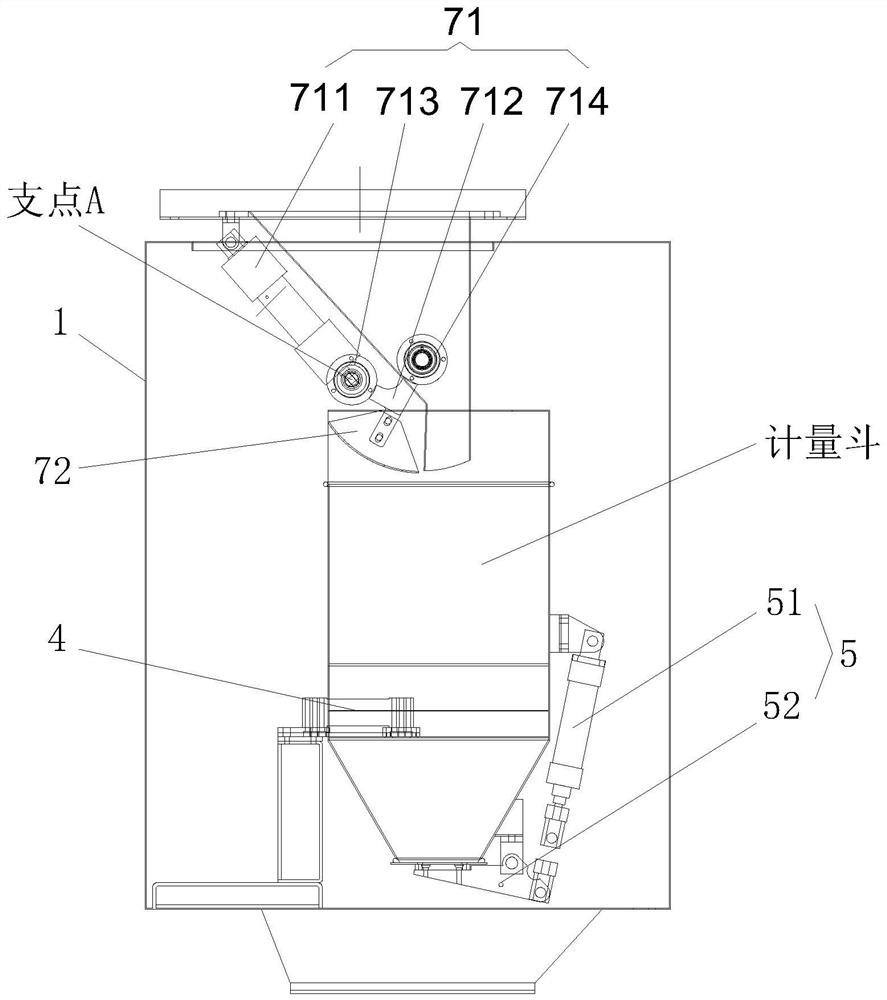

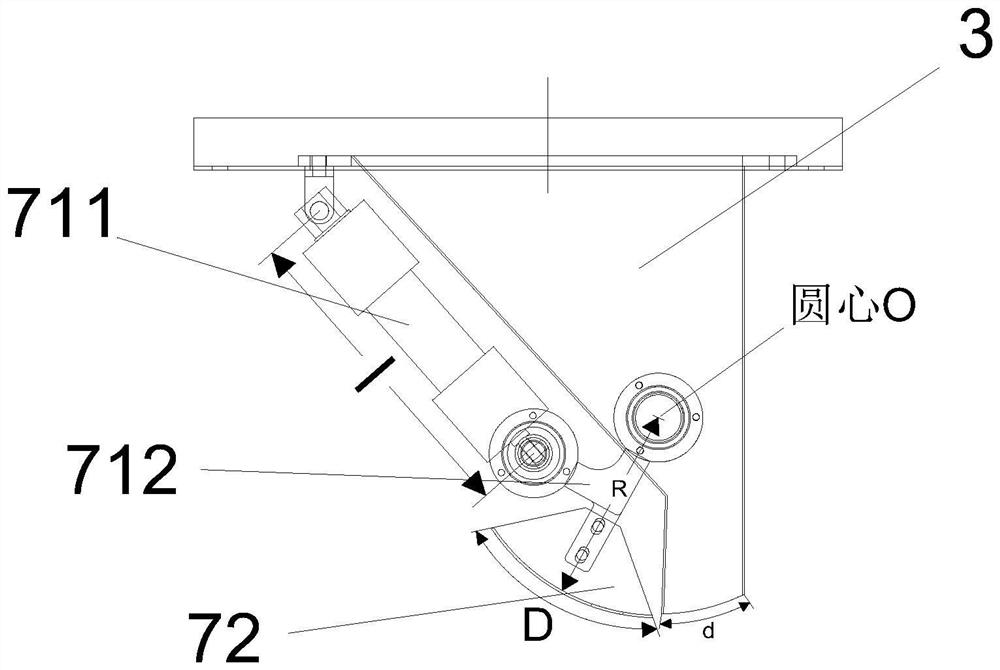

[0059] Such as Figure 1-8 As shown, an automatic integrated weighing device for finished magnesia includes a housing 1. There are multiple groups of weighing devices 2 arranged in the housing 1, and each group of weighing devices 2 is provided with feeding materials from top to bottom. The bucket 3, the weighing and measuring assembly 4 and the unloading mechanism 5 are respectively connected with the main control terminal 6 through electrical signals.

[0060] The weighing and metering assembly 4 in the present application comprises a load cell and a metering hopper, the load cell is arranged on the outside of the metering hopper, and a discharge mechanism 5 metering hopper is installed at the discharge port at the bottom of the metering hopper for collecting from the feed hopper 3 The magnesia material flowing down weighs the material in the weighing hopper through the weighing sensor. The above-mentioned weighing and measuring component 4 is a conventional weighing and measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com