Large-span arch rib temporary buttress reverse pre-pressing detection method

A temporary buttress and detection method technology, which is applied in the direction of measuring devices, strength characteristics, and the use of stable tension/pressure test material strength, etc., can solve the problems of lack of detection methods such as bracket pre-compression detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

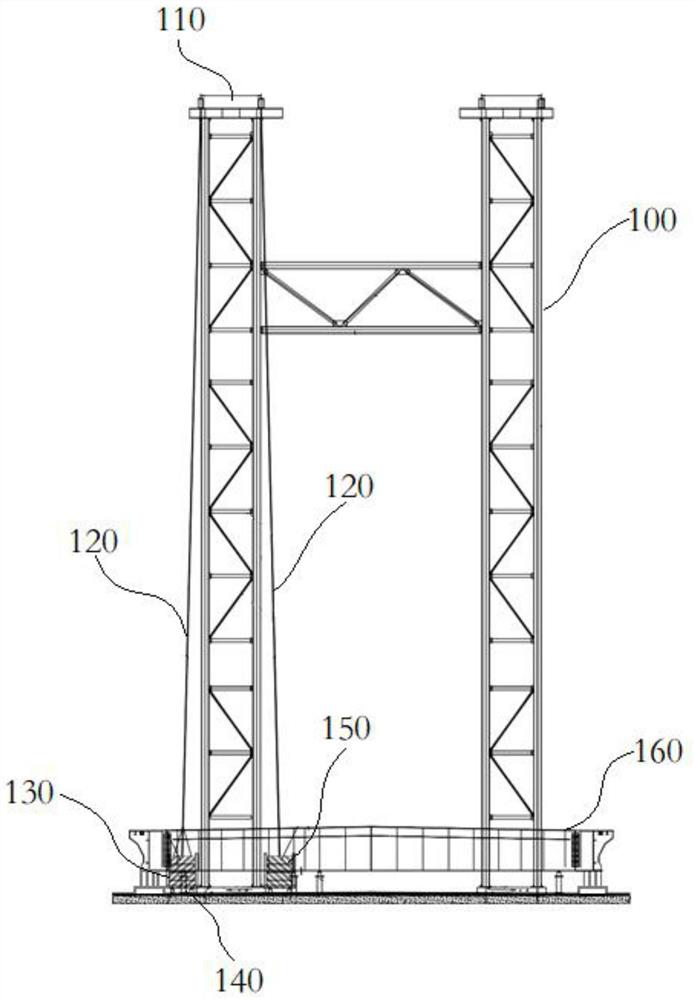

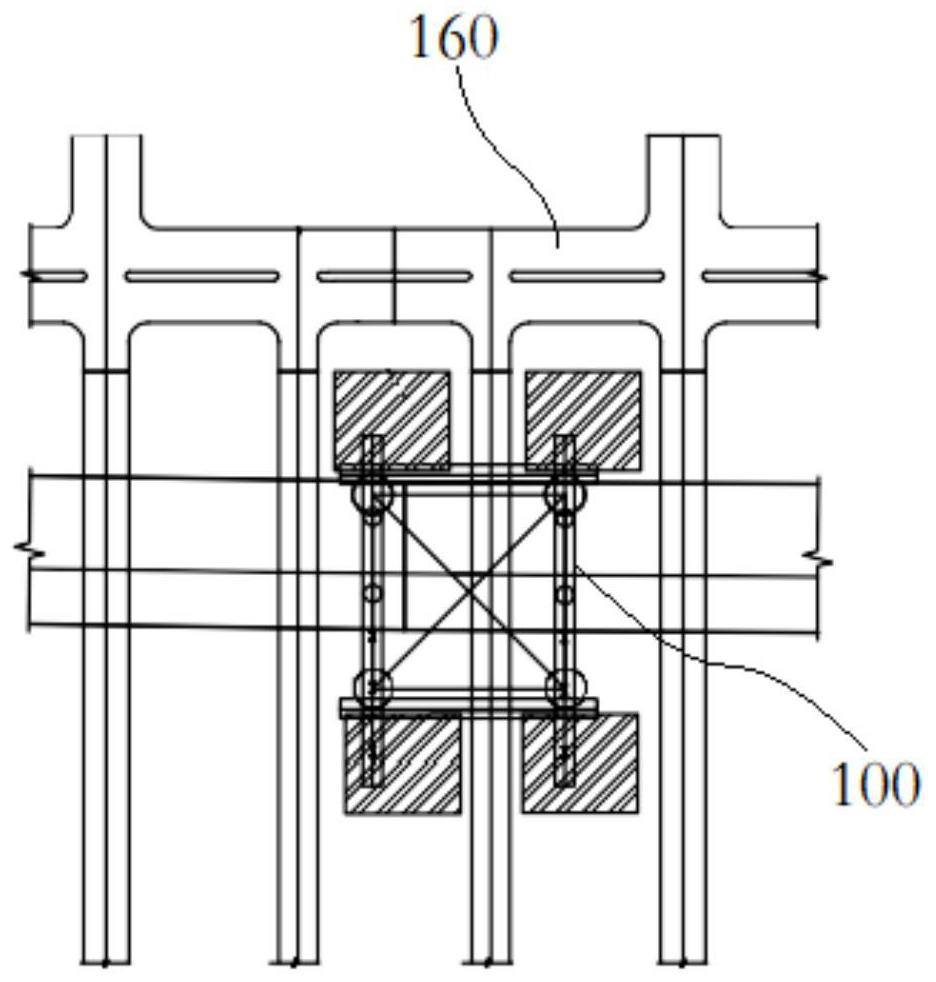

[0030] Such as Figure 1~2 As shown, this embodiment provides a method for detecting reverse preloading of temporary buttresses with large-span arch ribs, which includes the following steps:

[0031] S1, bracket 100 selection

[0032] Select a set of supports 100 with the highest temporary supports at the mid-span of the large-span arch rib;

[0033] In the actual construction process, according to the shape of the large-span arch rib, multiple sets of brackets 100 with different heights will be temporarily built to support different arch rib sections; the detection method in this embodiment adopts the method of sampling detection, through Sampling tests are carried out on the temporary supports to evaluate the bearing capacity of the temporary supports. In this embodiment, the highest set of supports 100 are selected for preload testing;

[0034] S2, distribution beam 110 installation

[0035] Install the distribution beam 110 at the highest point of the bracket 100 select...

Embodiment 2

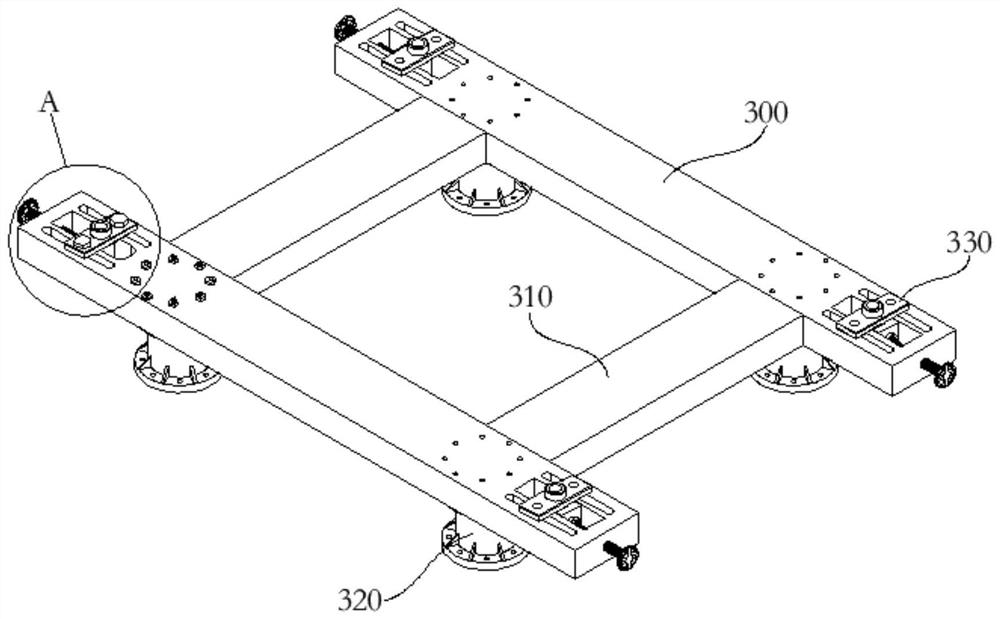

[0054] This embodiment provides a distribution beam, which is used to realize the installation of the distribution beam at the highest position of the support in Embodiment 1.

[0055] Such as image 3 As shown, in this embodiment, the distribution beam includes support plates 300 arranged in parallel, and the support plates 300 are connected by connecting plates 310. The lower plate surface of the support plate 310 is provided with a support column 320 connected to the uppermost end of the bracket 100, Both ends of the supporting column 320 are provided with a connecting flange 410, and the connecting flange 410 is connected to the corresponding supporting plate 310 and the support 100 by bolts; Anchors 330 .

[0056] In this embodiment, the connection plate 310 is connected to the support plate 300 by welding, so that the support plate 300 and the connection plate 310 form a structure that is compatible with the uppermost end of the bracket 120, wherein one end of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com