FPC flexible wire harness connecting plate structure for fuel cell stack inspection

A fuel cell stack and fuel cell technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., to achieve the effects of reducing the number of wiring harnesses, enhancing anti-seismic performance, mass power density and volume power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

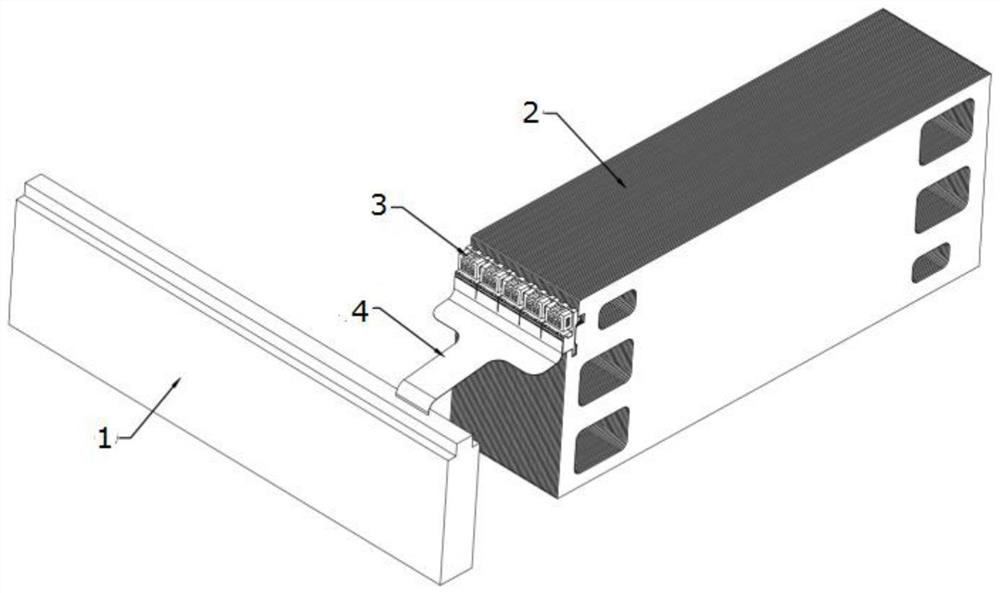

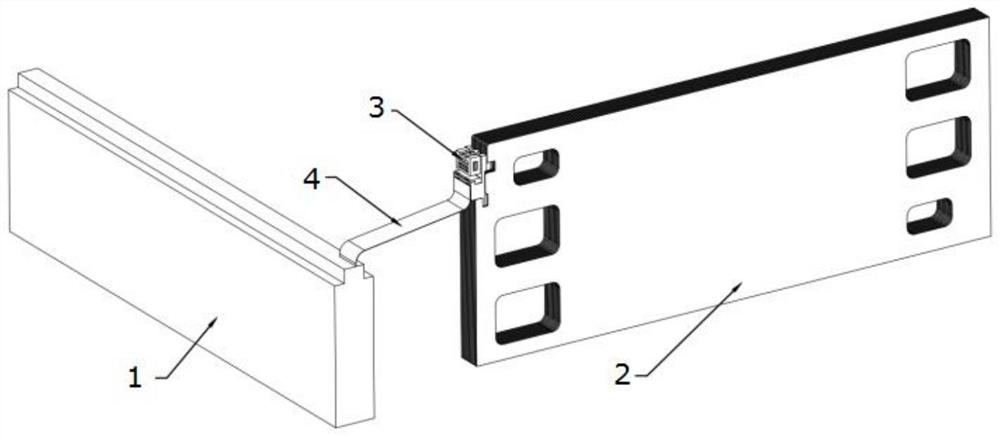

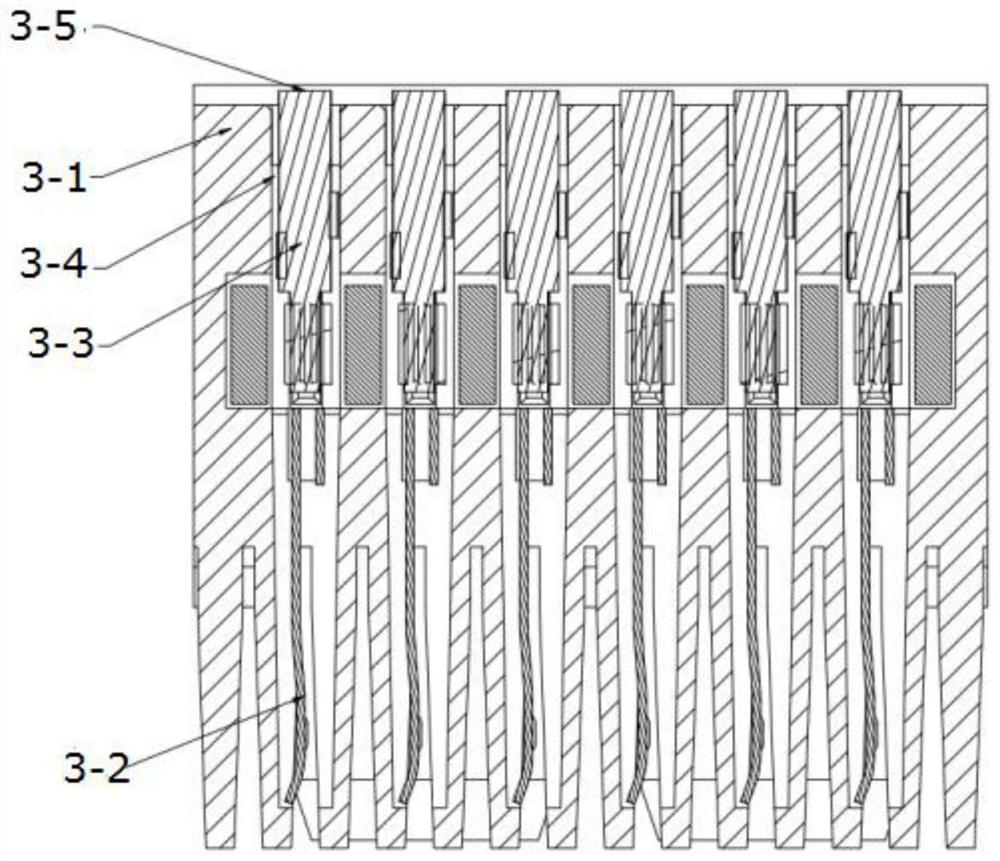

[0032] In preferred embodiment 1, such as figure 1 , figure 2 and image 3 As shown, a FPC flexible wiring harness connection plate structure for fuel cell stack inspection, including stack battery pack 2, fuel cell voltage inspection module 1, bipolar board connector 3 and FPC flexible circuit board 4, bipolar board The connector 3 is connected to the stack battery pack 2, the bipolar plate connector 3 includes a main structure 3-1 and a terminal 3-2, the terminal 3-2 is assembled on the main structure 3-1, and the terminal 3-2 is connected to the welded copper Column 3-3, the welding copper column 3-3 is fixed on the main structure 3-1 through the rubber plug 3-4, the welding end surface 3-5 is set on the welding copper column 3-3, and the welding end surface 3-5 is connected with the FPC flexible circuit board 4 phases are connected, and the other end of the FPC flexible circuit board 4 is connected with the fuel cell voltage inspection module 1 .

[0033] In Embodiment...

Embodiment 2

[0037] In preferred embodiment 2, a fuel cell stack inspection FPC flexible wiring harness connection plate structure, such as image 3 As shown, the FPC flexible circuit board 4 adopts a higher integrated design, the FPC flexible circuit board 4 can be connected to multiple bipolar board connectors 3 by welding, etc., and a single bipolar board connector 3 is adapted to a single stack battery pack 2. The FPC flexible circuit board 4 is connected to multiple bipolar board connectors 3 to realize the connection of fuel cell stacks with multiple numbers of nodes. Embodiment 2 ensures high adaptability to fuel cell stacks with multiple numbers of nodes. sex.

Embodiment 3

[0039]A fuel cell, according to the technical content in Embodiment 1 or Embodiment 2, the fuel cell is assembled by using the technical content in Embodiment 1 or Embodiment 2 in the fuel cell, and the fuel cell stack has relatively high vibration resistance , mass power density and volume power density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com