Optical module aging device

An aging device and optical module technology, applied in the field of optical communication, can solve the problems of large heat generation, easy over-temperature, poor temperature uniformity, etc., and achieve the effect of uniform temperature, ensuring temperature uniformity, and ensuring accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

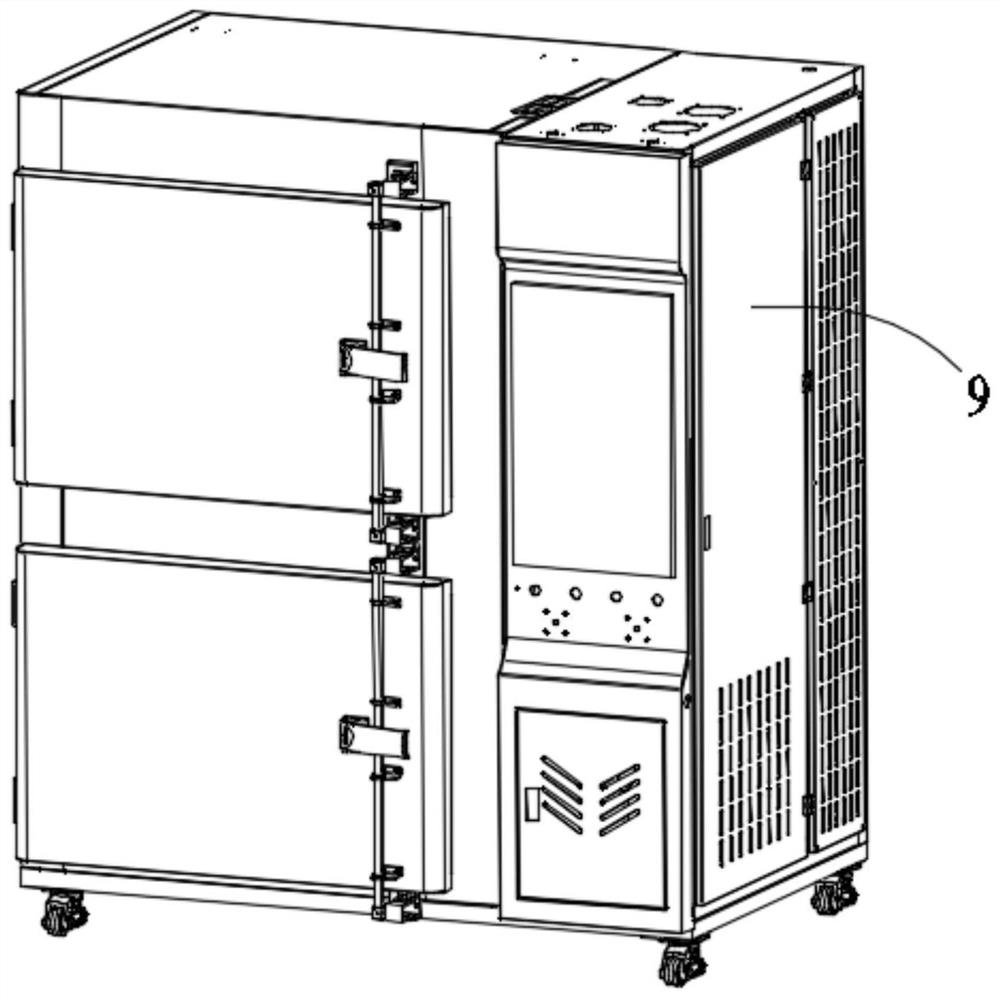

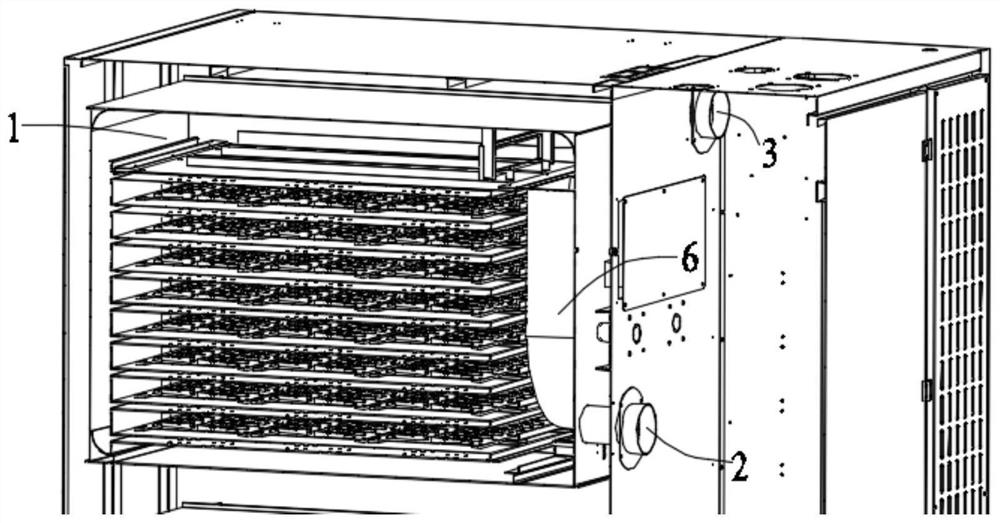

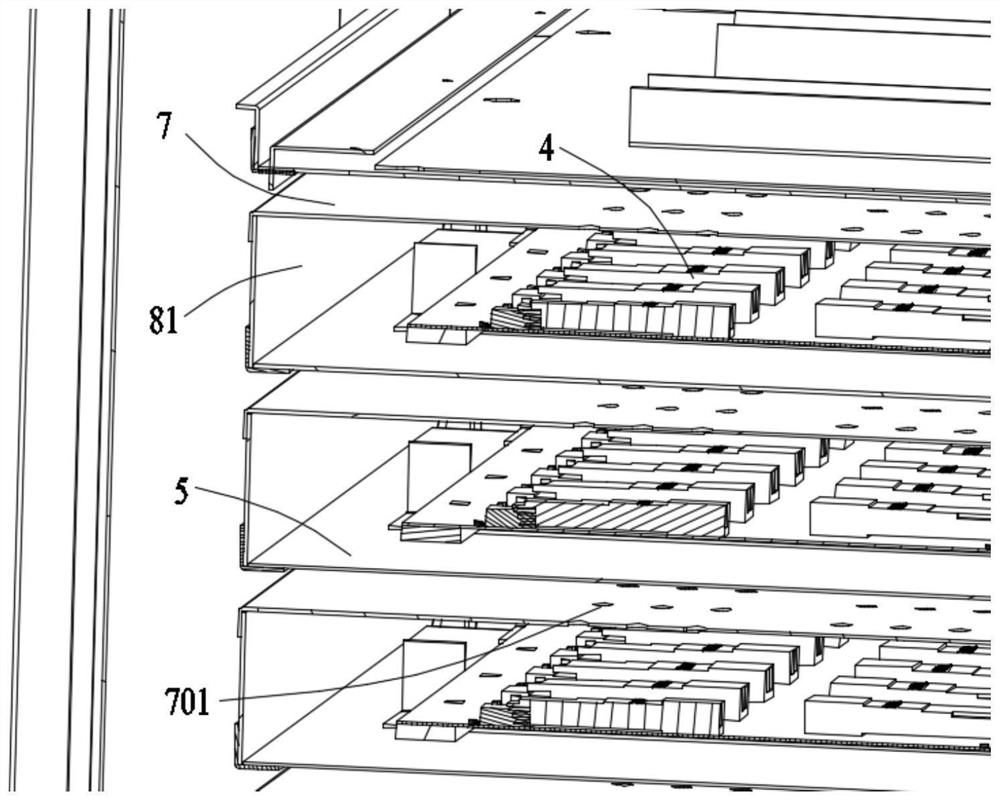

[0024] Embodiment 1: An optical module aging device, including at least one heating chamber 1, at least one air inlet 2 and at least one pressure relief port 3 are opened on the heating chamber 1, and several heating chambers are installed in the heating chamber 1 On the carrier plate 5 where the optical module 4 is placed, several carrier plates 5 are vertically spaced in the heating chamber 1, and a first cavity area is formed between the uppermost carrier plate 5 and the heating chamber 1 A centrifugal fan 6 is installed in the heating chamber 1 and located on one side of several carrier boards 5, and the other side of the several carrier boards 5 and the heating chamber 1 are surrounded by a space that communicates with the first cavity area. The second cavity area;

[0025] An air shower plate 7 is arranged between two adjacent carrier plates 5, and one end of the air shower plate 7 close to the second cavity area is connected with the carrier plate 5 below it through a f...

Embodiment 2

[0031] Embodiment 2: An optical module aging device, including at least one heating chamber 1, at least one air inlet 2 and at least one pressure relief port 3 are opened on the heating chamber 1, and several heating chambers are installed in the heating chamber 1 On the carrier plate 5 where the optical module 4 is placed, several carrier plates 5 are vertically spaced in the heating chamber 1, and a first cavity area is formed between the uppermost carrier plate 5 and the heating chamber 1 A centrifugal fan 6 is installed in the heating chamber 1 and located on one side of several carrier boards 5, and the other side of the several carrier boards 5 and the heating chamber 1 are surrounded by a space that communicates with the first cavity area. The second cavity area;

[0032] An air shower plate 7 is arranged between two adjacent carrier plates 5, and one end of the air shower plate 7 close to the second cavity area is connected with the carrier plate 5 below it through a f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap