Method and device for diagnosing pre-charging circuit and power battery system

A technology of pre-charging circuit and diagnostic method, which is applied in the direction of electrical connection testing, etc., can solve the problem that it is difficult to accurately locate the fault location of pre-charging circuit components, and achieve the effect of convenient and timely replacement and maintenance of faulty components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

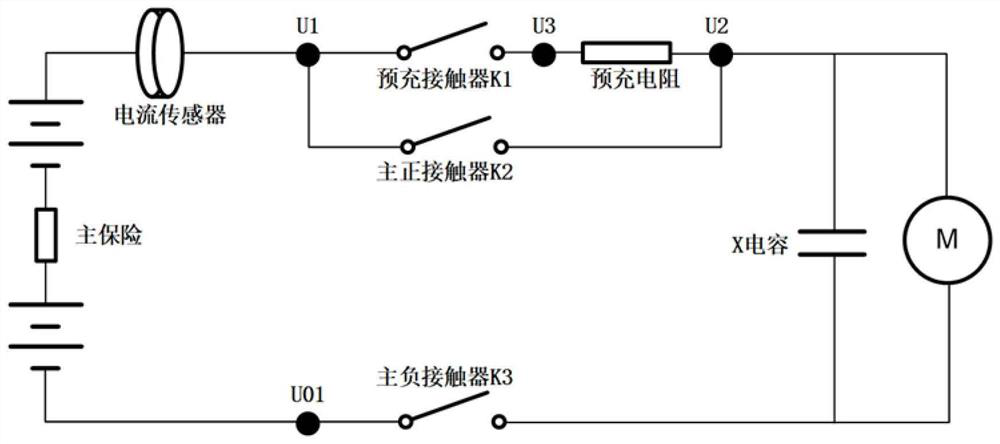

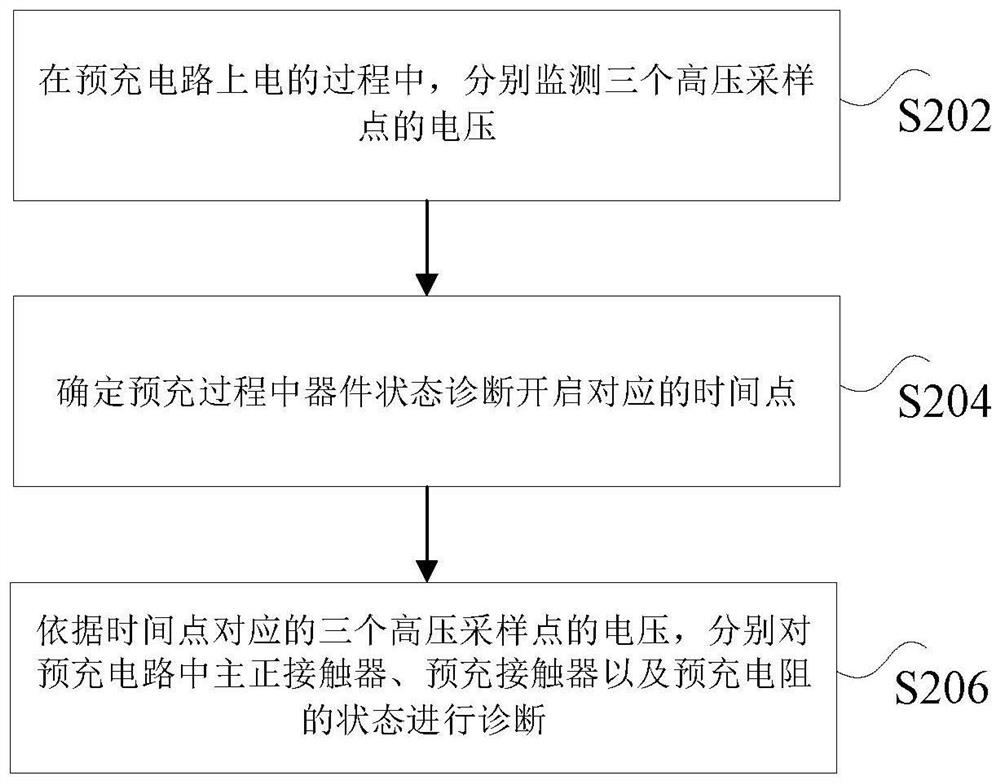

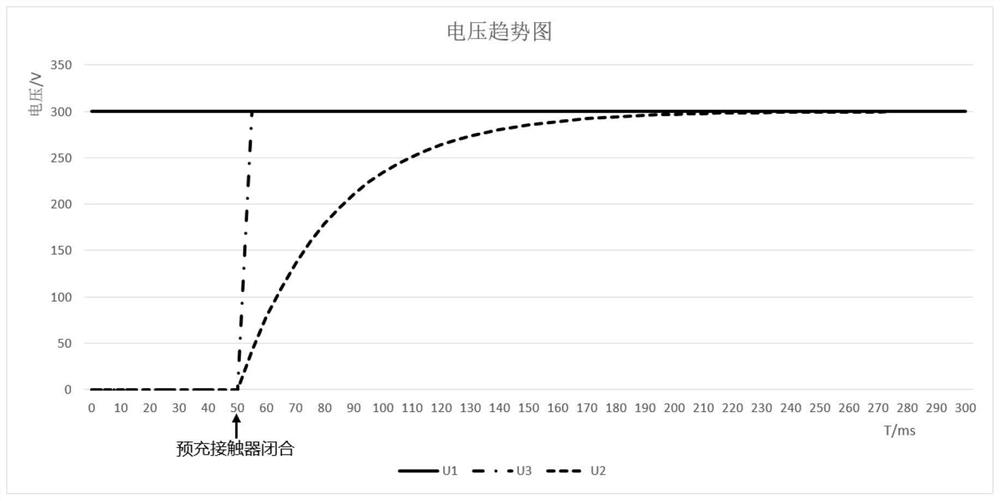

[0026] figure 1 is a schematic diagram of a precharge circuit according to an embodiment of the present invention, such as figure 1As shown, the pre-charging circuit includes battery, current sensor, main positive contactor, main negative contactor, pre-charging contactor, pre-charging resistor, X capacitor, vehicle load and main fuse. The pre-charging circuit has three high-voltage sampling Among them, the first high-voltage sampling point is located on the line between the pre-charging contactor and the positive pole of the battery, the second high-voltage sampling point is located on the line between the pre-charging resistor and the vehicle load, and the third high-voltage sampling point is located on the line between the pre-charging On the line between the charging contactor and the pre-charging resistor.

[0027] It should be noted that, in order to realize the separate diagnosis of the pre-charging contactor and the pre-charging resistor, it is necessary to set the pr...

Embodiment 2

[0061] According to another aspect of the embodiment of the present invention, a diagnostic device for a pre-charging circuit is also provided, the pre-charging circuit includes a battery, a current sensor, a main positive contactor, a main negative contactor, a pre-charging contactor, a pre-charging resistor, X capacitor, vehicle load and main insurance, the pre-charging circuit has three high-voltage sampling points, among which, the first high-voltage sampling point is located on the line between the pre-charging contactor and the positive pole of the battery, and the second high-voltage sampling point is located on the line between the pre-charging contactor and the positive pole of the battery. On the line between the resistor and the vehicle load, the third high-voltage sampling point is located on the line between the pre-charging contactor and the pre-charging resistor. Figure 5 is a schematic diagram of a diagnostic device for a precharge circuit according to an embod...

Embodiment 3

[0073] According to another aspect of the embodiments of the present invention, there is also provided a power battery system, including a memory and a processor, a computer program is stored in the memory, and the processor is configured to execute any one of the above-mentioned precharging circuits through the computer program diagnostic method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com