Material receiving adjusting part for dividing green bodies for automatic production system

A technology of production system and adjustment department, which is applied in the direction of conveyor objects, transportation and packaging, and can solve problems such as reliability and complex operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the objects and advantages of the present invention, the present invention will be specifically described below with reference to the embodiments. It should be understood that the following text is only used to describe one or more of the specific embodiments of the present invention, and the scope of the specifically requested protection of the present invention is not strictly limited. The existing structures not described in detail in the present invention are implemented in accordance with the prior art.

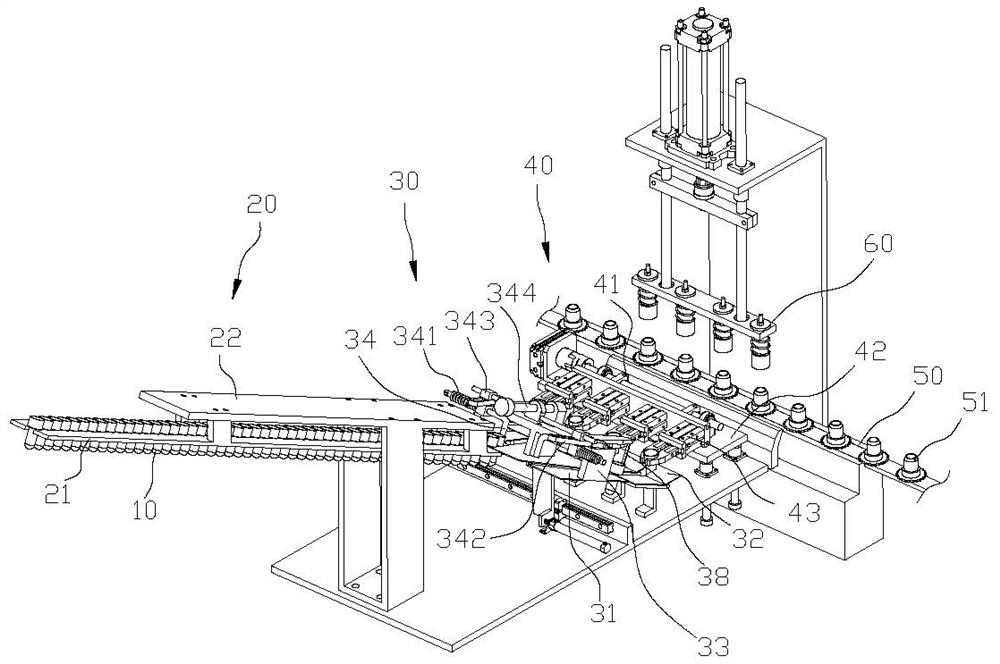

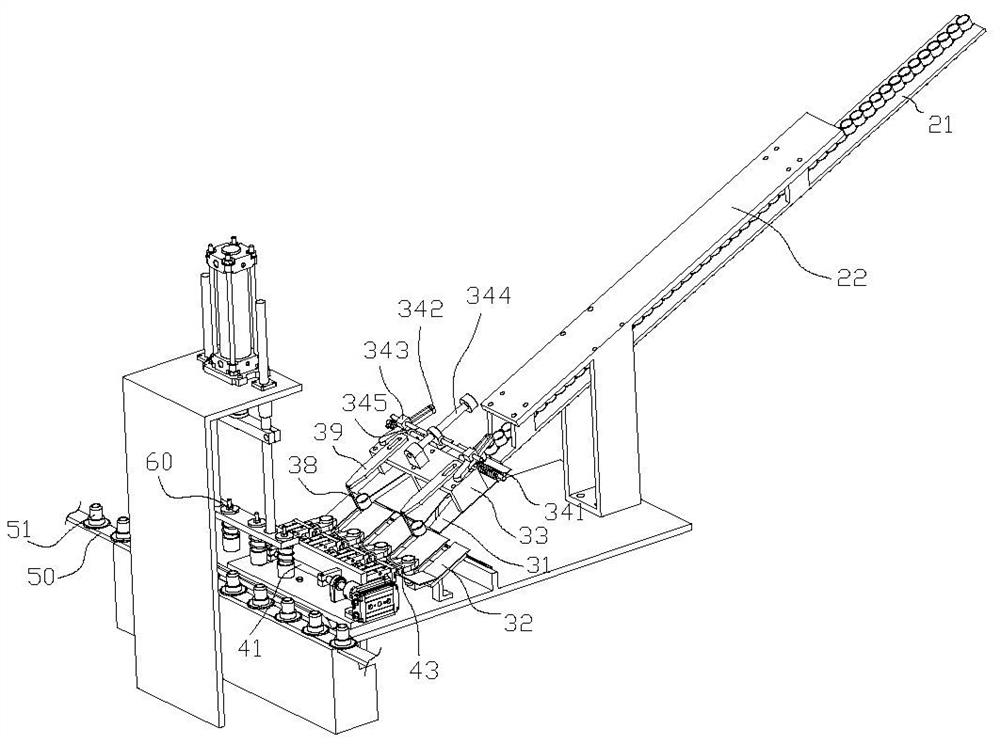

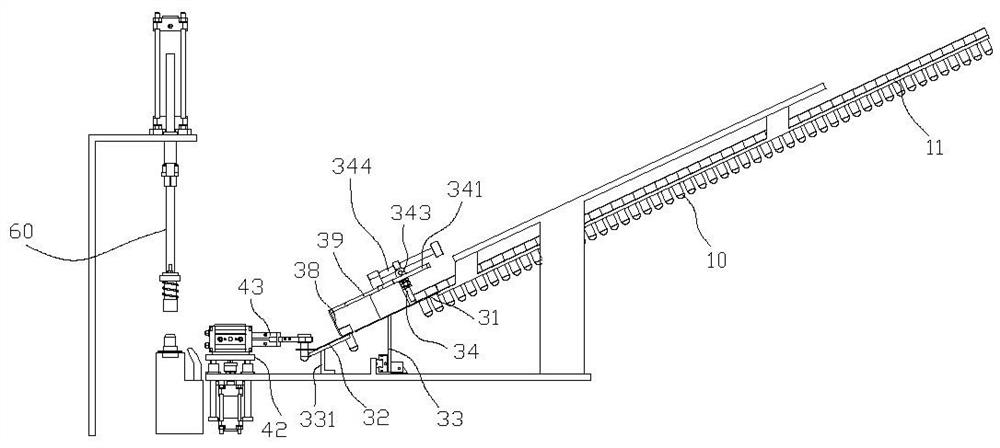

[0022] Such as Figure 1 ~ 4 As shown, a shifting device for blank 10 shifting means comprising a discharge unit 20 for disculating the blank 10 for distributing the blank 10 output by the discharge unit 20. A ranging unit 30, as well as each column of the blank 10 for the rotation unit 40 for the subsequent processed. Further scheme is: The substrate unit 30 is used to divide the blank 10 discharged from the discharge unit 20 into n first part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com