Probe head protective sleeve of probe and use method of probe head protective sleeve

A technology for protective sleeves and needles, which is applied to the parts of electrical measuring instruments, measuring devices, instruments, etc., can solve the problems of easy damage of needles, and achieve the effect of improving protection rate and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

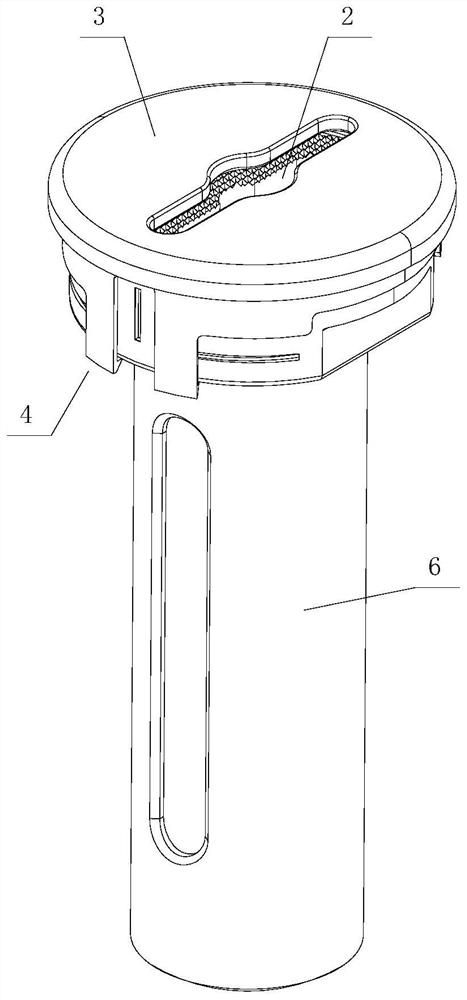

[0058] refer to Figure 5 As shown, a method for using the needle protection cover of a probe, for using the above-mentioned needle protection cover of the probe, comprises the following steps:

[0059] S11: Complete the assembly of the current needle head 2 and the current needle bar 1;

[0060] S12: covering the current needle 2 with the protective surface 3 to form protection for the current needle 2;

[0061] S13: Pass the voltage pin through the installation hole 5 on the protection surface 3.

[0062] After the current needle 2 and the current needle bar 1 are assembled, the current needle 2 is covered by the protective surface 3 to form protection for the current needle 2. At the same time, the installation of the subsequent voltage needle can be completed through the installation hole 5, so that the current needle 2 After the production and assembly are completed, it can be protected immediately, and the protection rate is improved.

Embodiment 2

[0064] refer to Image 6 As shown, a method for using the needle protection cover of a probe, for using the above-mentioned needle protection cover of the probe, comprises the following steps:

[0065] S21: Complete the assembly of the current needle head 2 and the current needle bar 1;

[0066] S22: Cover the current needle 2 with the protective surface 3 to form protection for the current needle 2;

[0067] S23: Pass the voltage pin through the installation hole 5 on the protection surface 3.

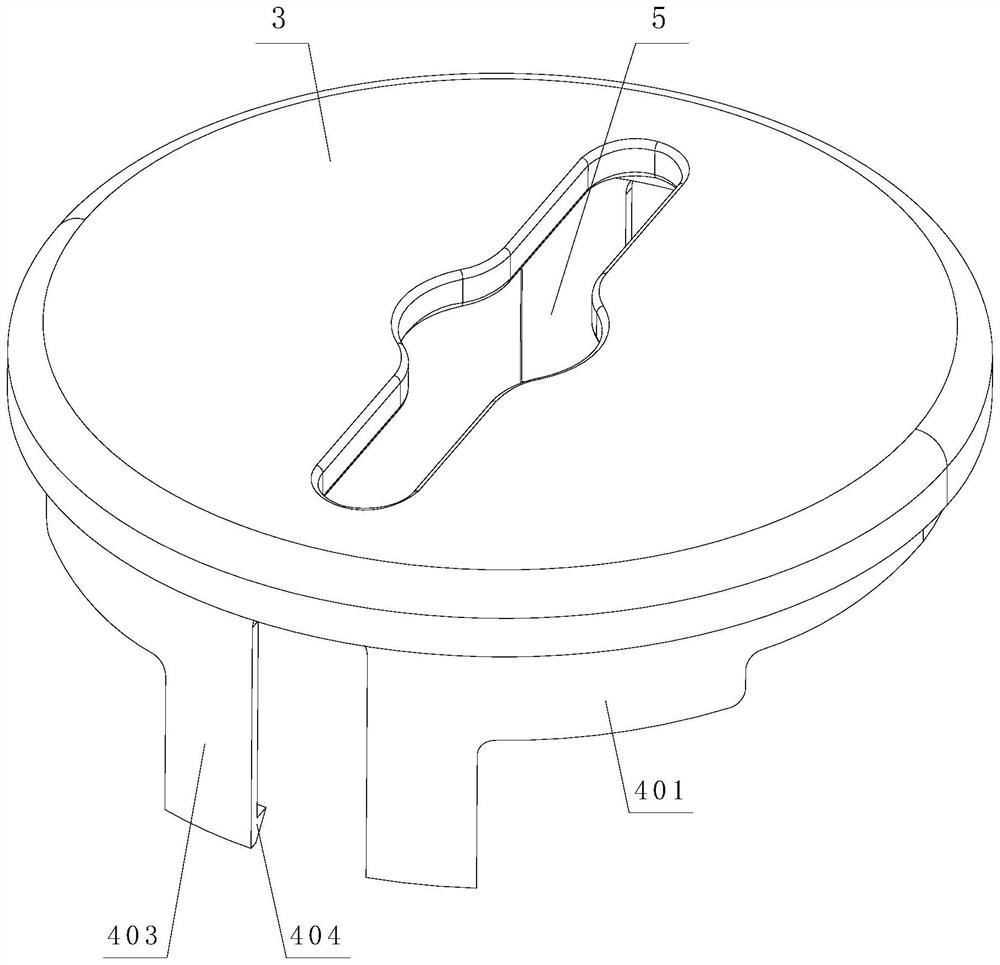

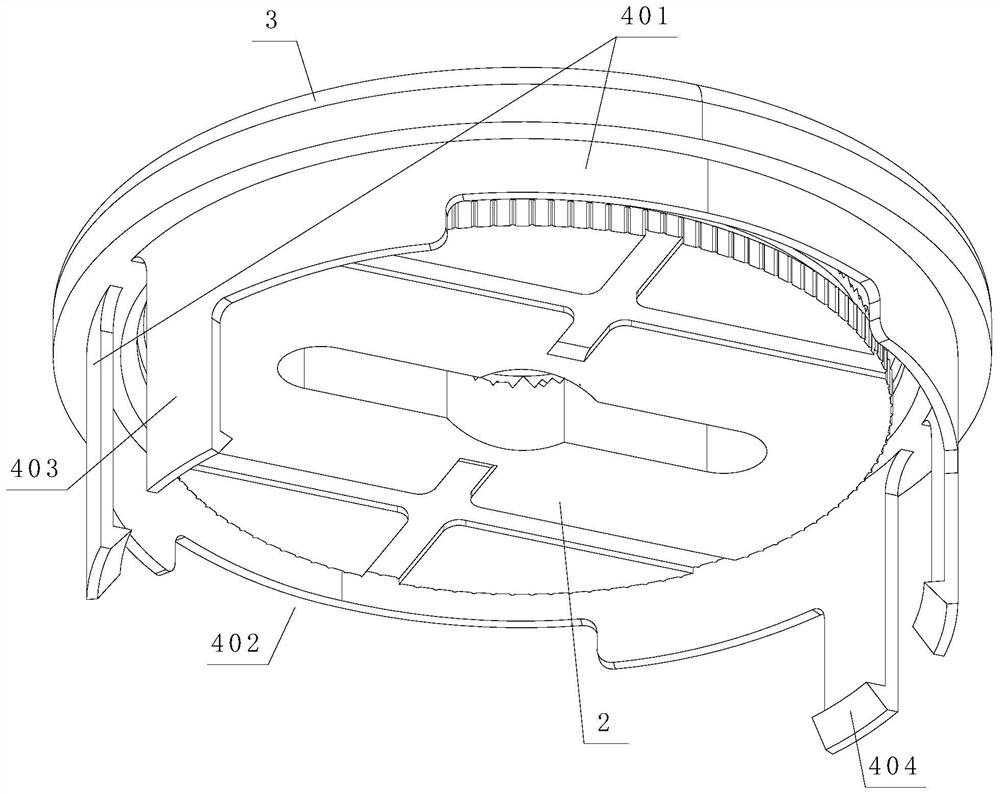

[0068] Among them, refer to figure 1 As shown, S22 includes:

[0069] S221: Cover the current needle 2 with the protection surface 3 to form protection for the current needle 2;

[0070] S222: Rotate the protective surface 3, so that the concave portion 402 of the first limiting member 4 is rotated to the platform surface.

[0071] Compared with Embodiment 1, in Embodiment 2, after the protection surface 3 is covered with the current needle 2, the protection surface 3 is rotated,...

Embodiment 3

[0073] refer to Figure 7 As shown, a method for using the needle protection cover of a probe, for using the above-mentioned needle protection cover of the probe, comprises the following steps:

[0074] S31: Complete the assembly of the current needle head 2 and the current needle bar 1;

[0075] S32: covering the current needle 2 with the protective surface 3 to form protection for the current needle 2;

[0076] S33: Pass the voltage pin through the installation hole 5 on the protection surface 3.

[0077] Among them, refer to figure 1 As shown, the S32 includes:

[0078] S321: covering the current needle 2 with the protective surface 3 to form protection for the current needle 2;

[0079] S322: Wrap the first extension part 403 around the receiving part of the current needle bar 1, and clamp the second extension part 404 on the bottom of the receiving part.

[0080] Compared with Embodiment 1, in Embodiment 3, after the protective surface 3 is covered with the current n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com