A hand wheel processing device

A technology of processing device and handwheel, which is applied to the device and coating of the surface coating liquid, can solve the problems such as the reduction of the diameter of the handwheel, the influence of the valve assembly operation, and the inability of the handwheel to be inserted into the threaded rod, etc., to achieve Guaranteed normal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

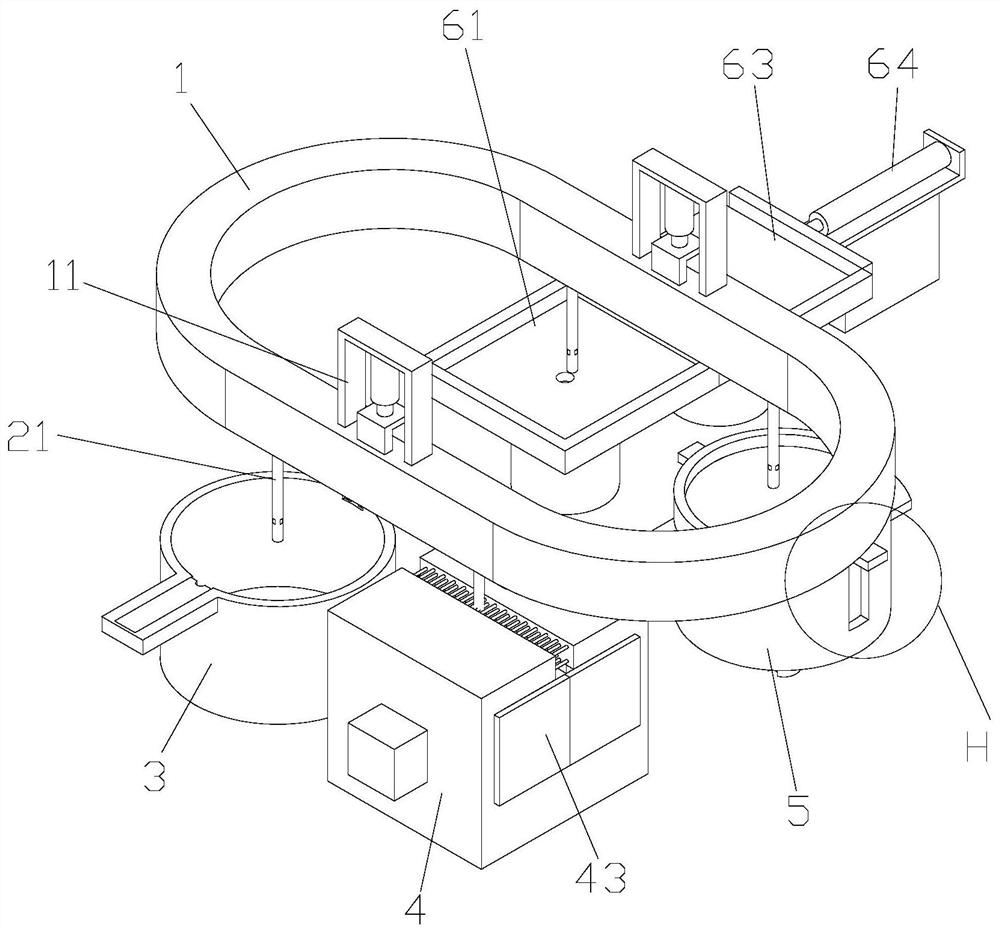

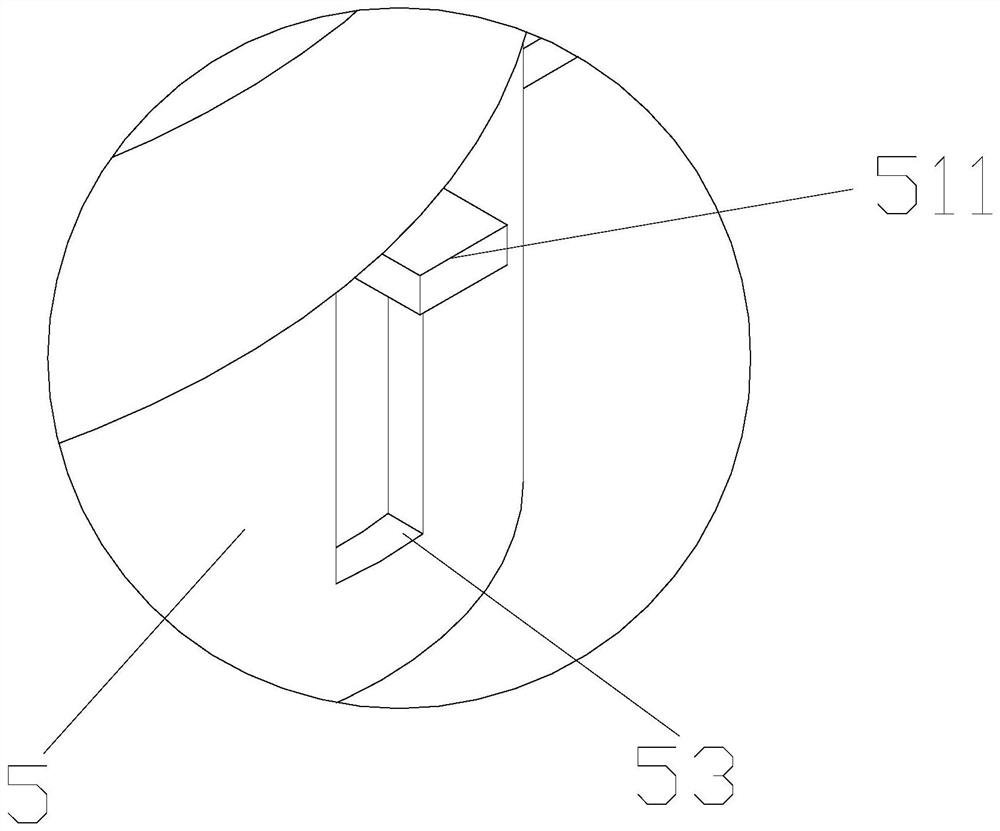

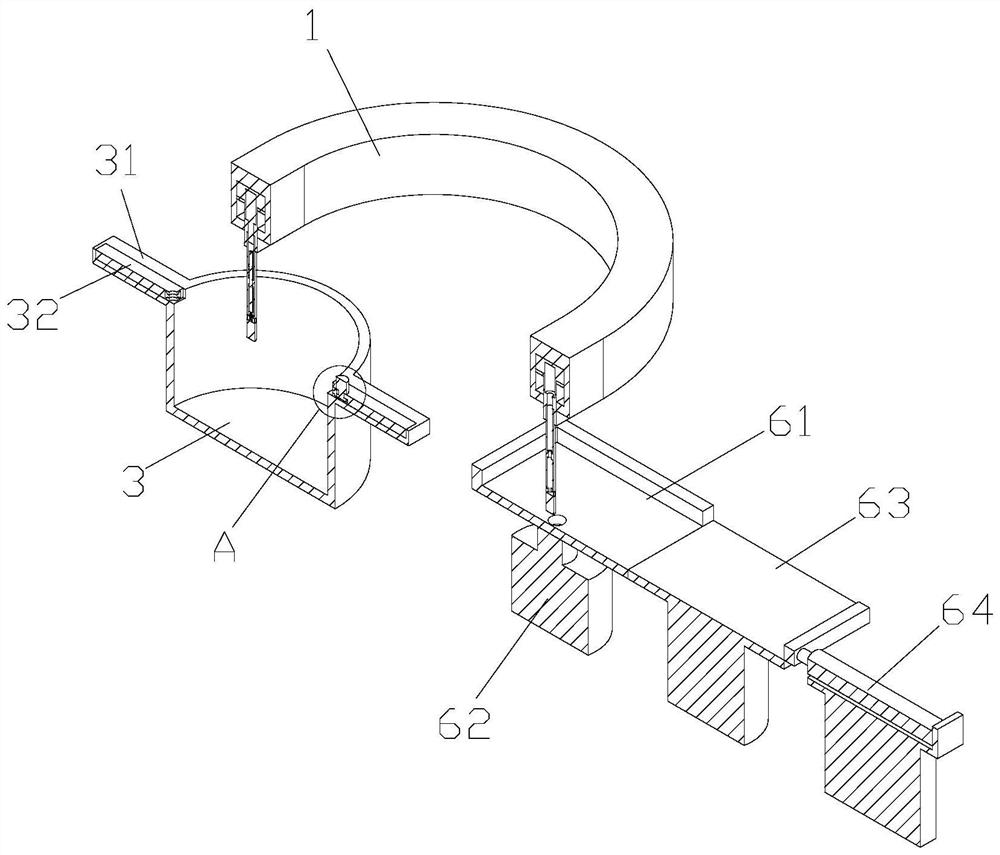

[0034] like Figure 1-18 As shown, a handwheel processing device includes a guide rail 1, a guide block 2 arranged in the guide rail 1, a varnish dipping box 3 arranged under the guide rail 1, a paint dipping box 3 arranged on one side of the varnish dipping box 3 The drying box 4, the collecting box 5 arranged on one side of the drying box 4 and the first push plate 61 arranged on one side of the collecting box 5, the guide rail is a closed loop, and there are many a guide block, so that the processing device can work continuously and improve the processing efficiency of the hand wheel; the way the guide block moves in the guide rail is the prior art, and will not be repeated here; the bottom of the guide block 2 is provided with a first connection The rod 21, the first connecting rod 21 is provided with a cavity, the side wall of the cavity is provided with an opening, the opening is provided with a fixing block 24, and the side wall of the first connecting rod 21 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com