A valve processing technology

A processing technology and valve technology, which is applied in the direction of coating, pretreatment surface, and device for coating liquid on the surface, etc. It can solve the problem of affecting the valve assembly operation, the reduction of the diameter of the hand wheel, and the inability of the hand wheel to be inserted into the threaded rod, etc. problems, to achieve the effect of reducing the probability of safety accidents, increasing friction, and reducing labor burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

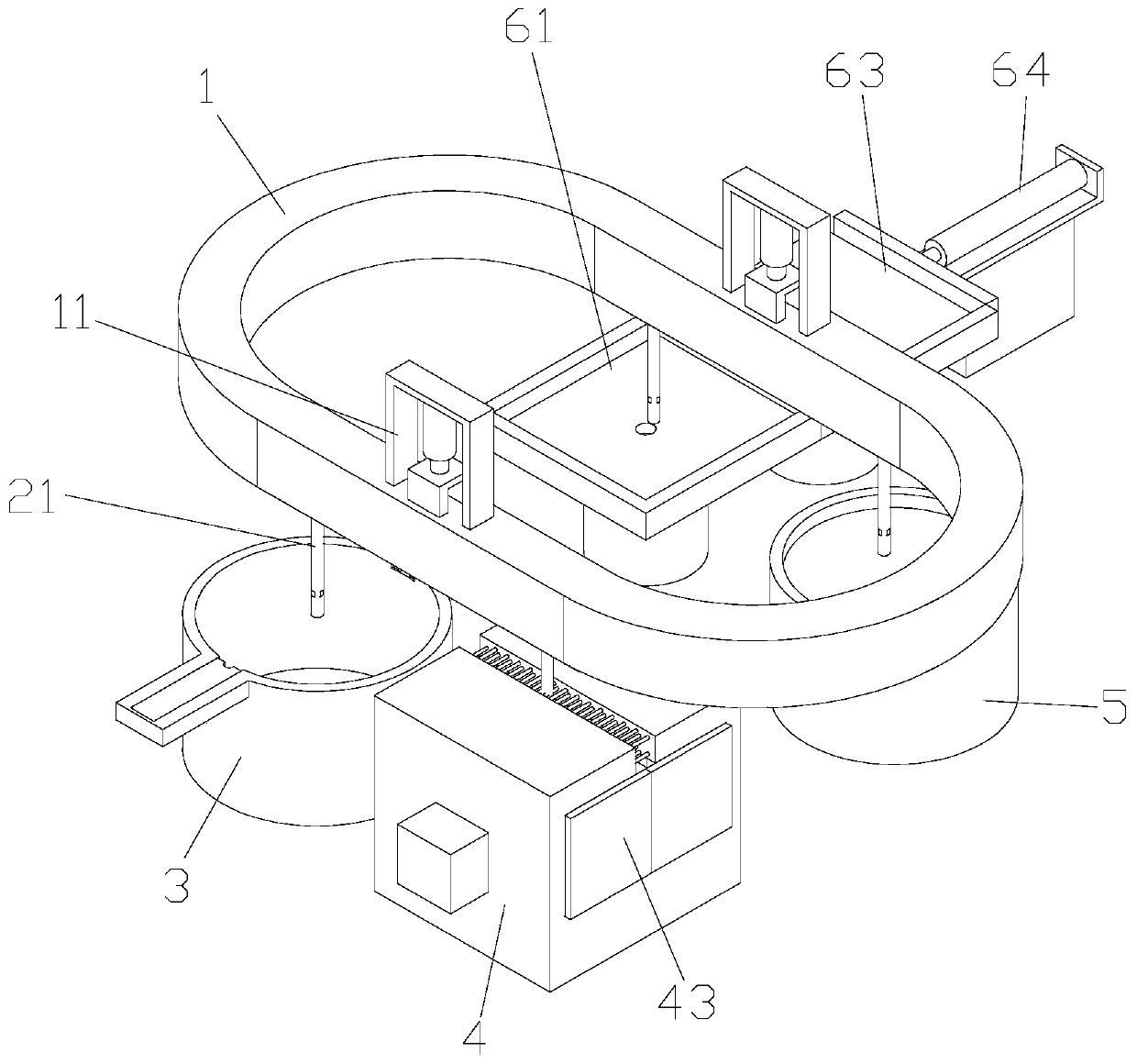

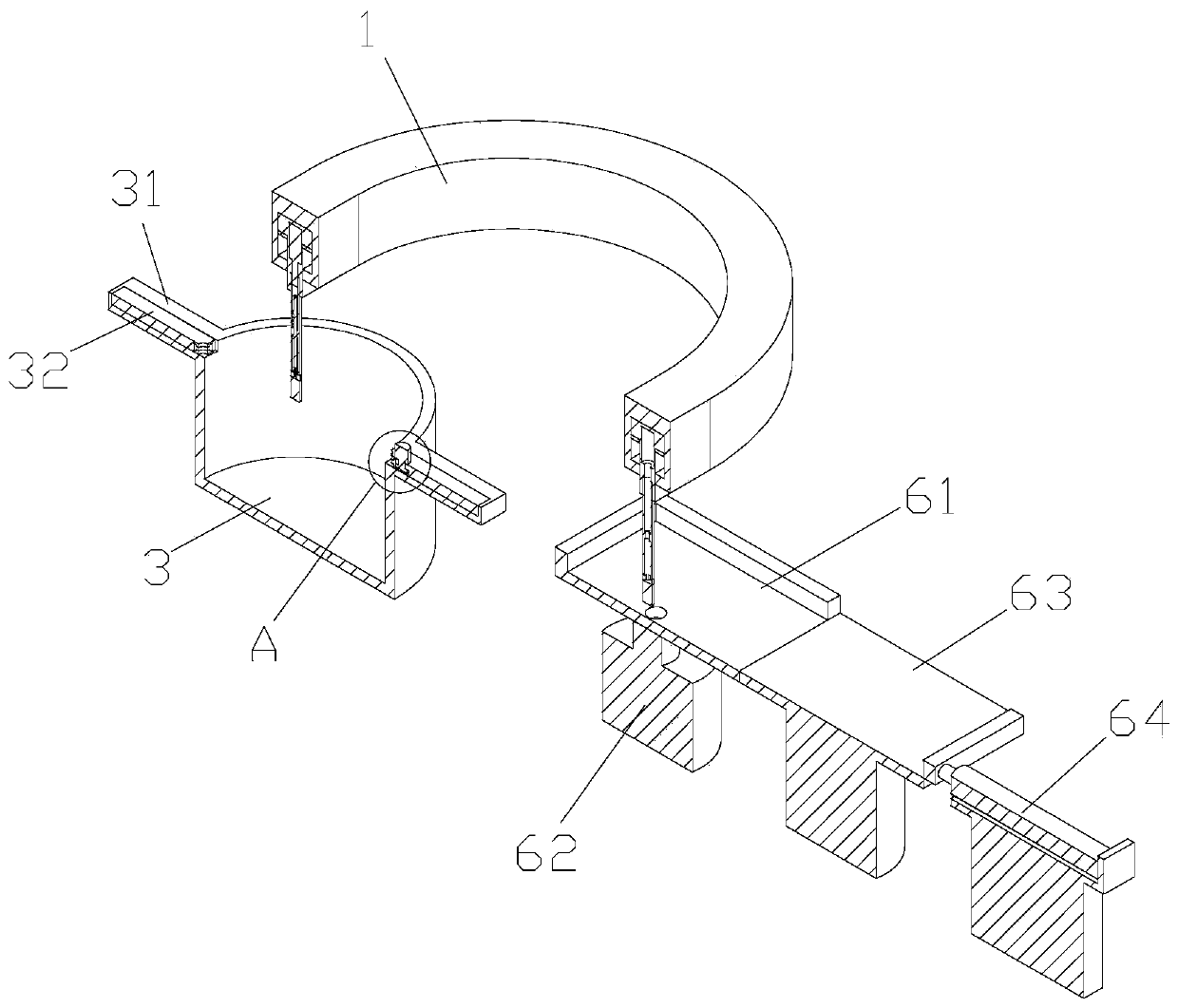

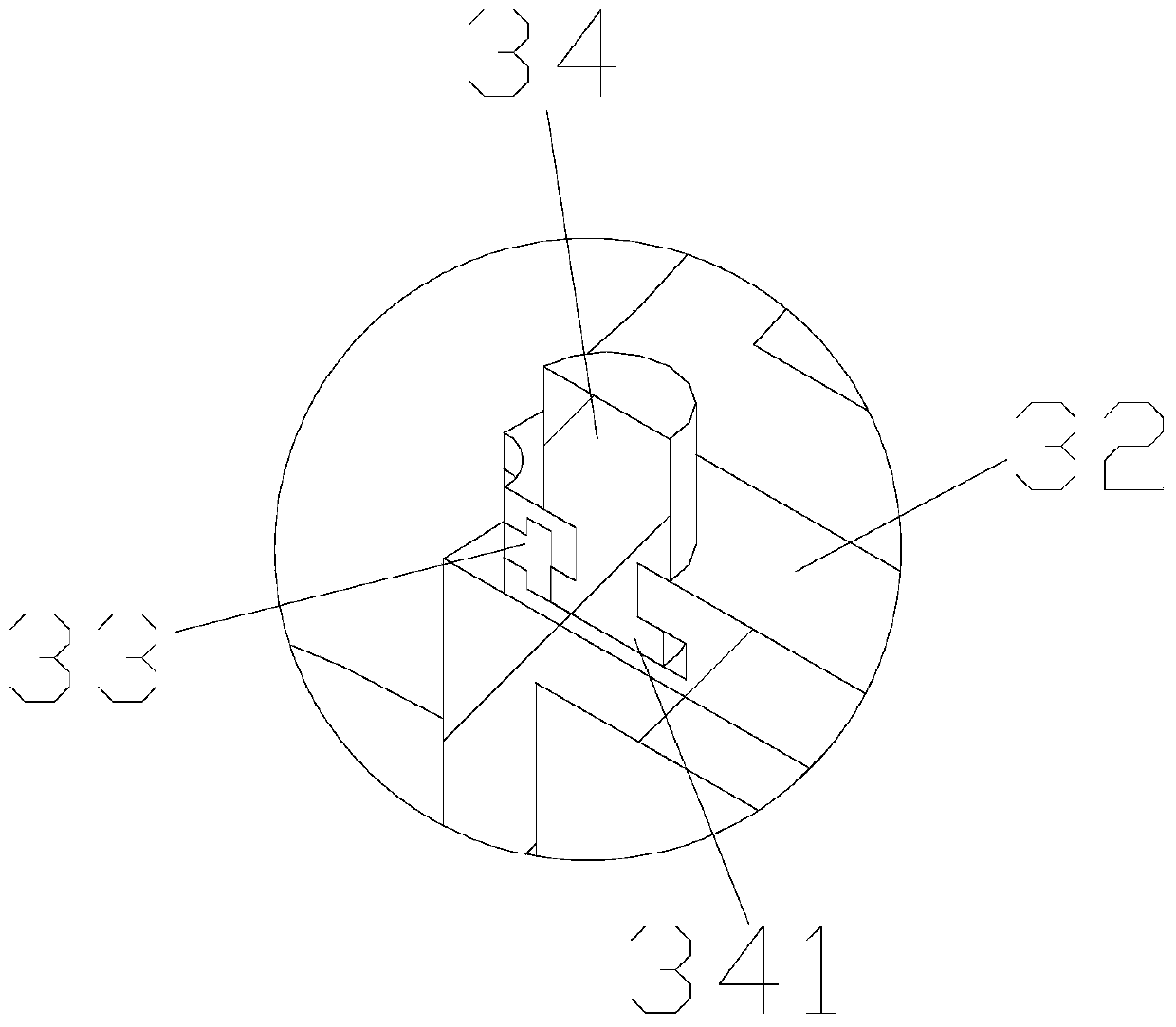

[0034] A valve processing technology, including: a. Purchasing valve body castings and forgings from outside, testing the purchased components, and repairing the castings that pass the testing before entering the workshop for processing; b. Carrying out the purchased valve stem rods Quenching and tempering treatment, turning, drilling and milling and deburring after passing the test; c. Put the purchased hand wheel on the hand wheel processing device, paint the surface of the hand wheel, and put the painted hand wheel on the One place for assembly and use; d. Test the purchased seals and fasteners, and put the seals and fasteners into the warehouse for standby after passing the test; e. Assemble all parts together to form a valve product; f. The assembled valves are inspected, and the qualified valves are packaged for delivery; the hard-sealed seals are directly drilled, milled, planed, inserted, deburred and polished after turning, and then the hammer rod is cleaned for anti-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com