Device for adjusting diameter of guide channel for bars

A technology for guiding channels and rods, which is applied in the field of size devices, and can solve problems such as the inability to maximize the guide surface of rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

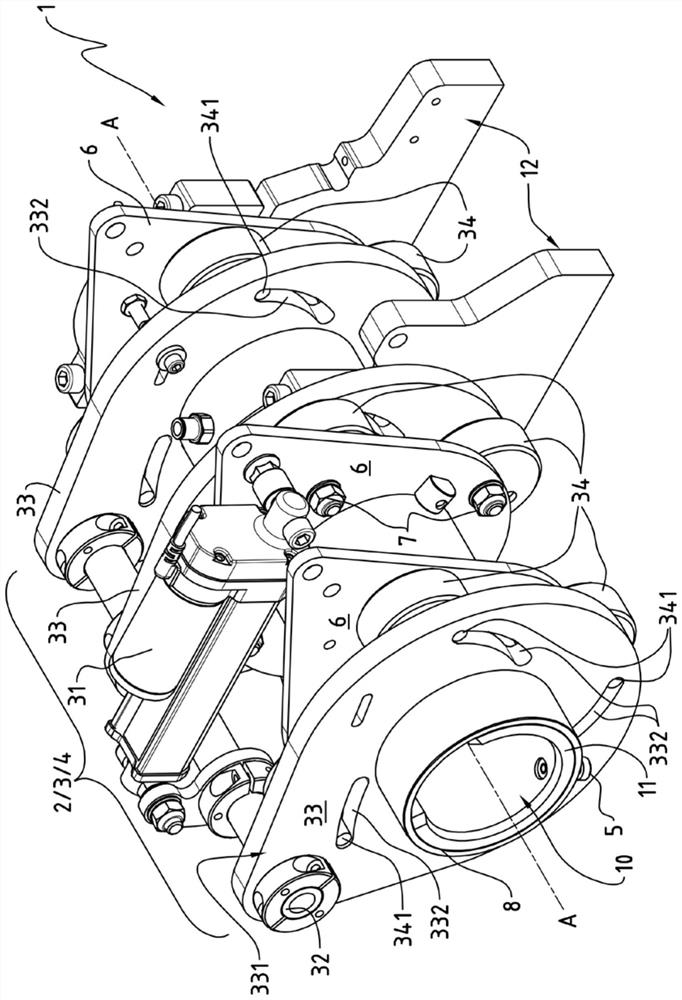

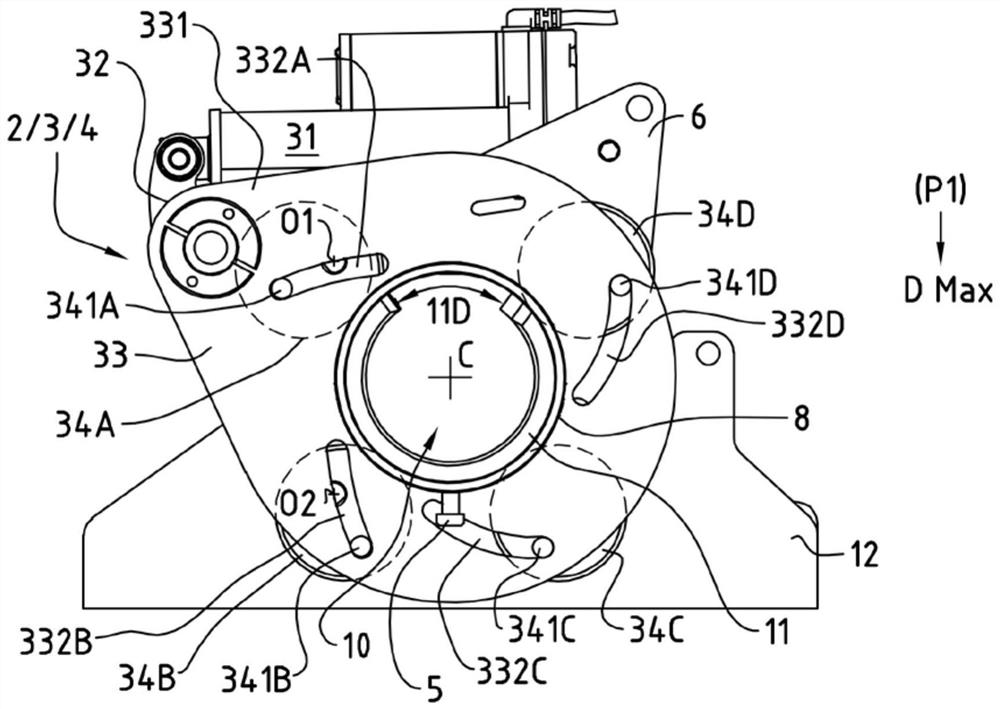

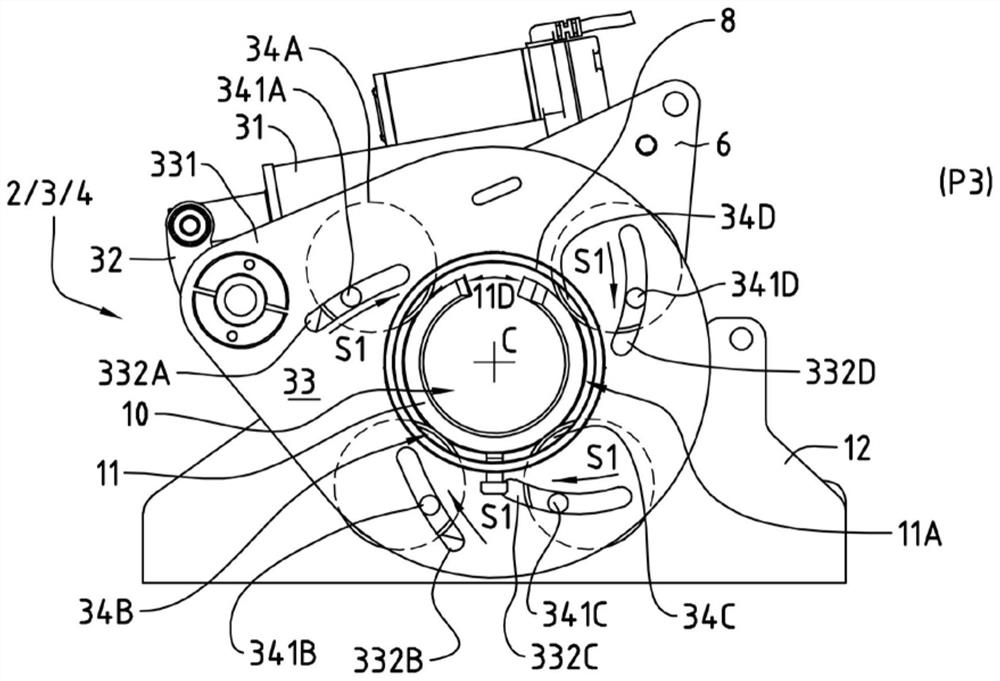

[0034] figure 1 Shows a perspective view of a bar feeder 1, here more specifically the bar feeder part equipped with a guide channel 10 according to a preferred embodiment of the invention, an adjustable guide element according to The guide channel is formed in sections by a one-piece flexible guide housing 11 made of, for example, polyurethane-based plastic or rubber material to dampen vibrations, and the guide The guide element is made integral with a cylindrical frame 8 similar to the front support by means of fixing pins 5 inserted in its bottom. In other words, the portion of the bar feeder shown in the Figures can itself be considered to constitute a front support.

[0035] The cylindrical frame 8 of the guide channel 10 is itself arranged on a base plate 12, here formed by several feet, and the means 2 for adjusting the diameter of the guide channel comprise together a clamping device 3 and a height adjustment device 4. The clamping device 3 acts on the flexible guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com