Full-automatic marshmallow machine and use method thereof

A cotton candy, fully automatic technology, applied in applications, instruments, confectionery, etc., can solve problems such as consumption and labor costs, and achieve the effect of improving efficiency, saving labor, and reducing the failure rate of patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

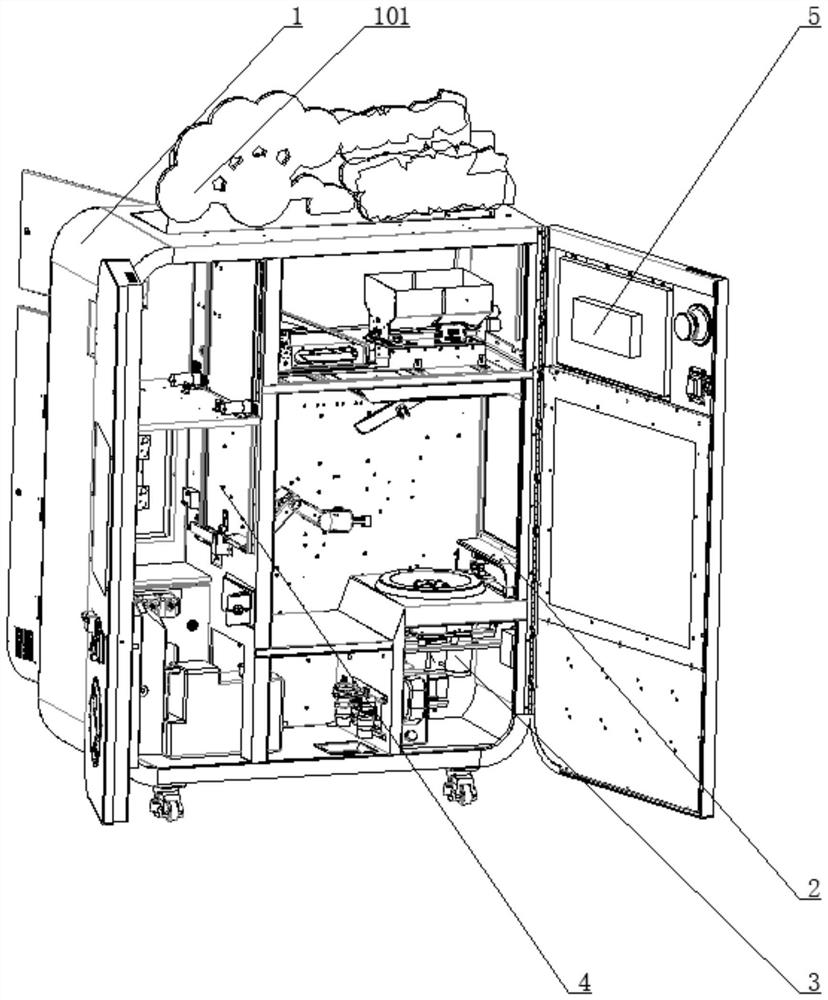

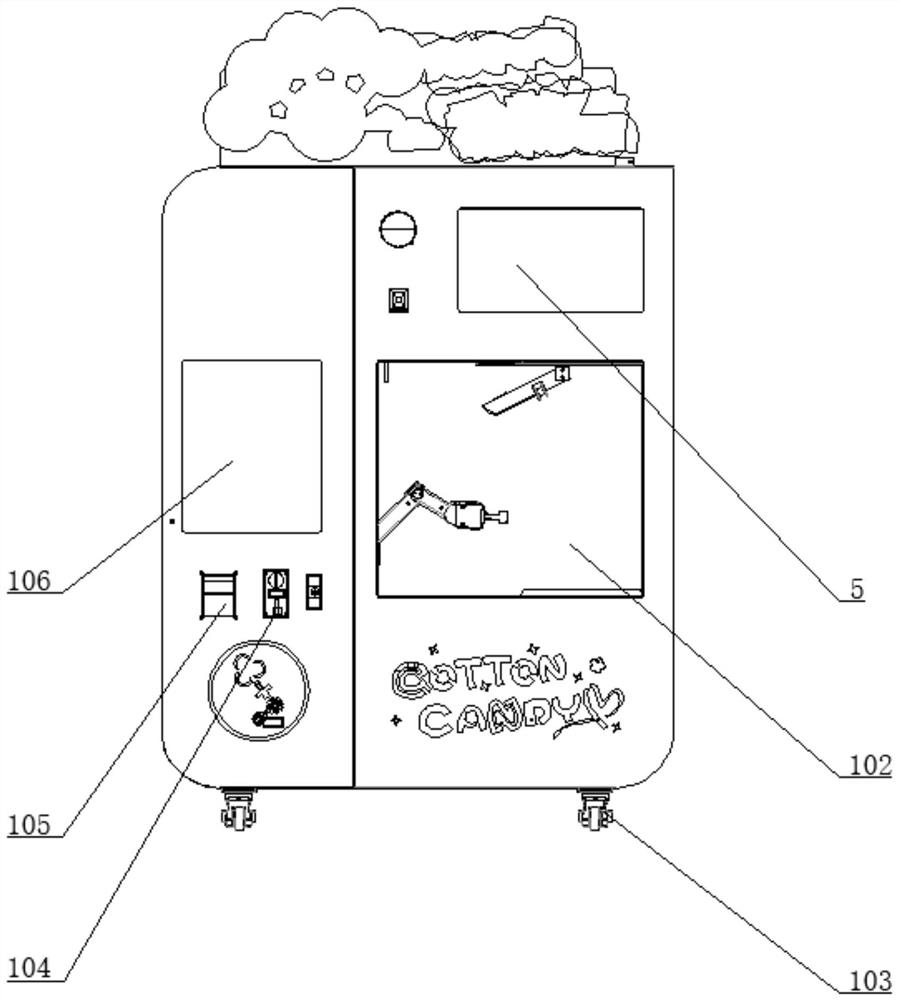

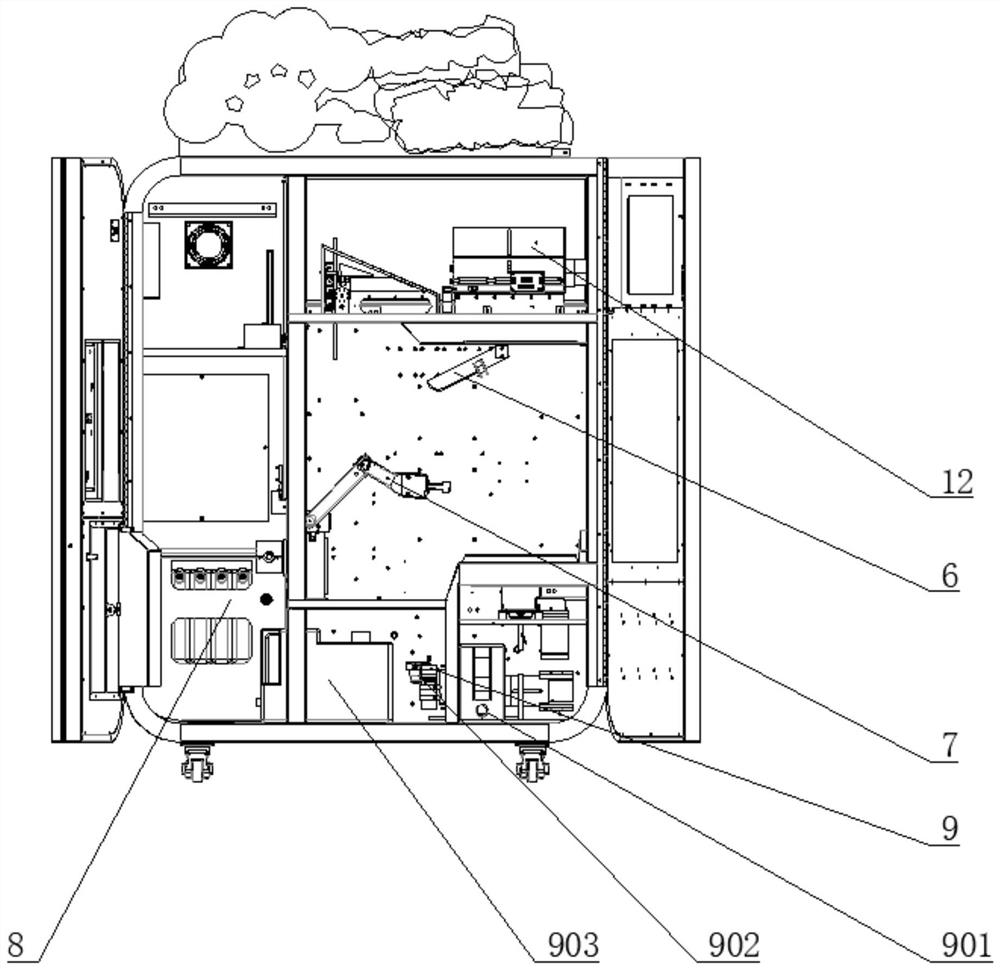

[0047] like Figure 1-Figure 9 As shown, the present invention includes a cotton candy machine 1, a human-machine interaction screen 5 is installed on the upper side of the outer side of the cotton candy machine 1, a burner module 3 is arranged on the bottom side of the inner cavity of the cotton candy machine 1, and the cotton candy machine 1 The side wall of the inner cavity is provided with a tail thread processing module 2 corresponding to the burner module 3, a water pump module 9 is installed at the middle of the inner cavity bottom of the cotton candy machine 1, and a water pump module 9 is installed at the other side of the inner cavity bottom of the cotton candy machine 1. A sugar lowering module 8, an automatic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com