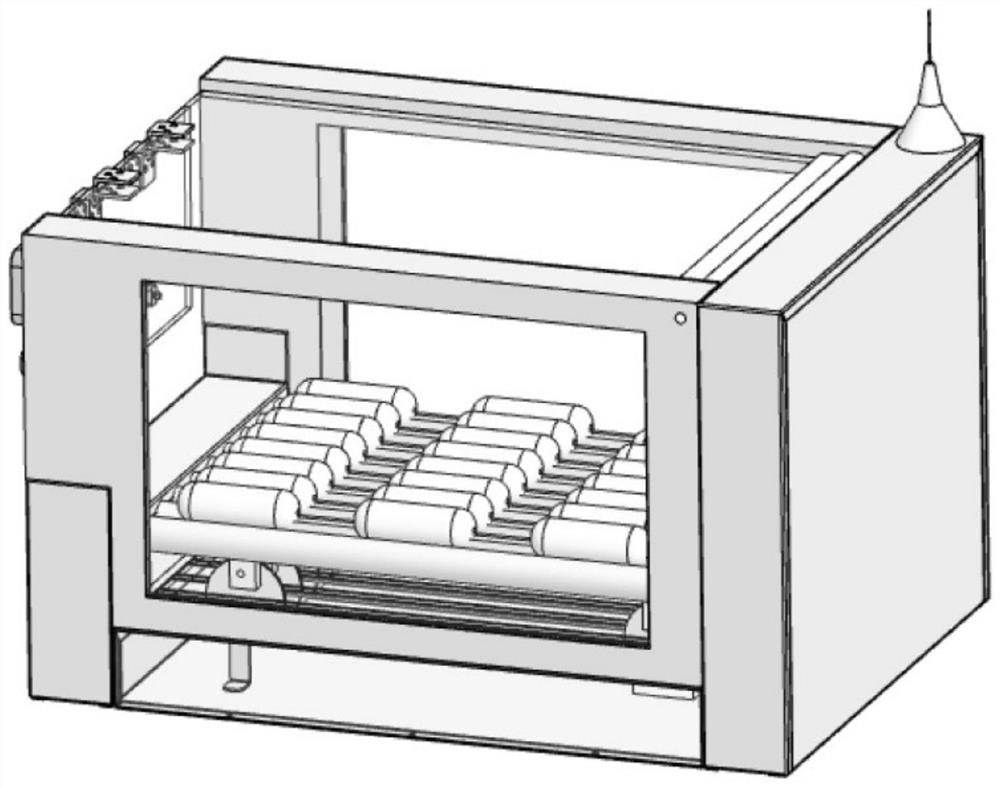

Control method for automatic baking machine

A control method and baking technology, applied to coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment with instrument control, etc., can solve the problem of reducing replenishment The speed, the transmission is prone to errors, the transmission device and the heating device are difficult to clean and maintain, etc., so as to solve the problem of labor occupation and avoid hygienic problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

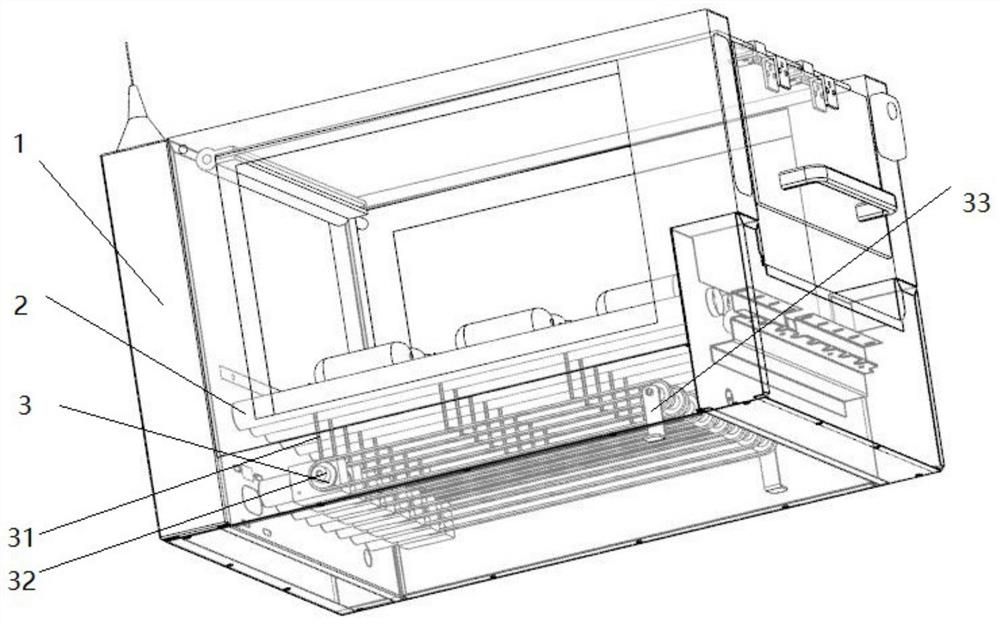

[0028] In the present invention, the stepping conveying device is not only used to push out the baked food for sale, but also can automatically load the baked food. The automatic roasting machine proposed by the present invention also includes a slideway with a side wall, docked with the stepping conveying device, the lower part of the slideway has a limiting structure, and the baked food on the slideway continuously slides to the limiting structure , the stepping conveying device continuously transfers the baked food at the limit structure to the heating roller through circular rotation. In order to facilitate loading, a button is provided on the side box of the slideway for the user to press to start the loading function. As a preferred embodiment, the limiting structure is a protruding bar at the bottom of the slideway, and the purpose of setting the limiting structure is to ensure that the baked foods step onto the moving parts one by one.

[0029] The moving part is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com