Heat pump type tobacco dryer and control method thereof

A control method, heat pump technology, applied in dryers, tobacco drying, drying, etc., can solve problems such as cracks in tobacco leaves, unsatisfactory baking effects, etc., to prevent overheating of the curing room and avoid excessive temperature rise in the curing room Fast, the effect of increasing the temperature rise rate of the oven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

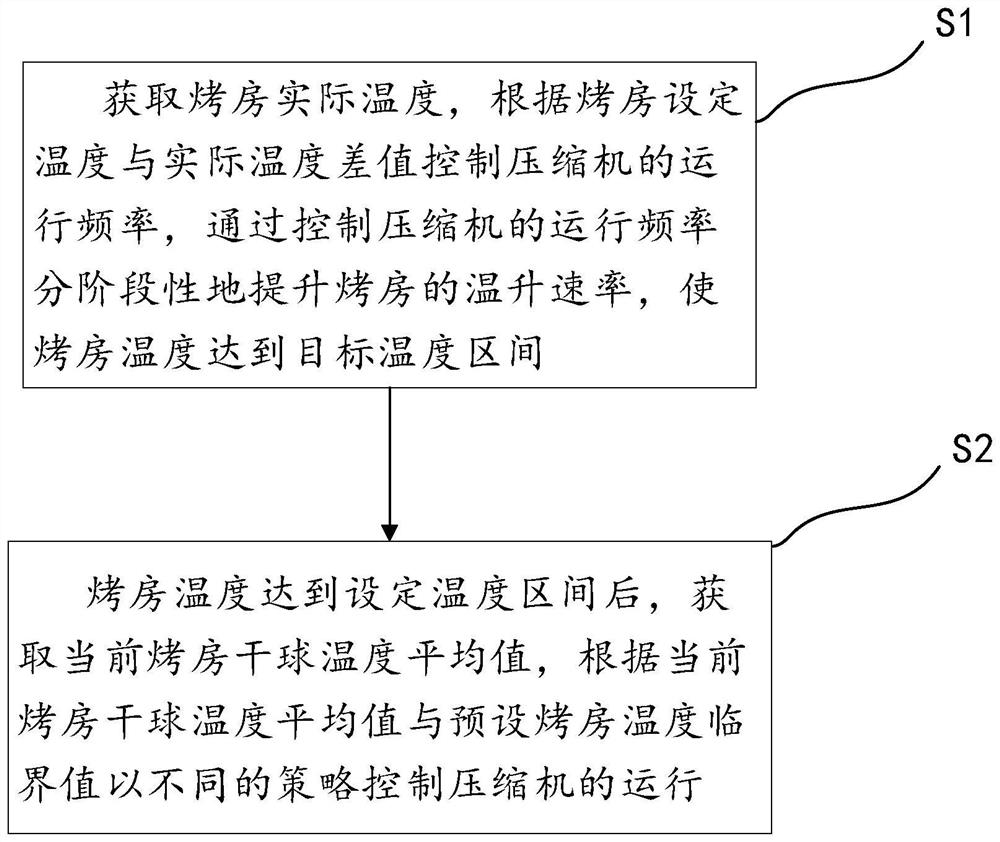

[0064] In this embodiment, a control method for a heat pump tobacco dryer is provided, such as figure 1 shown, including:

[0065] S1. Obtain the actual temperature of the baking room, control the operating frequency of the compressor according to the difference between the set temperature and the actual temperature of the baking room, and gradually increase the temperature rise rate of the baking room by controlling the operating frequency of the compressor, so that the temperature of the baking room reaches target temperature range.

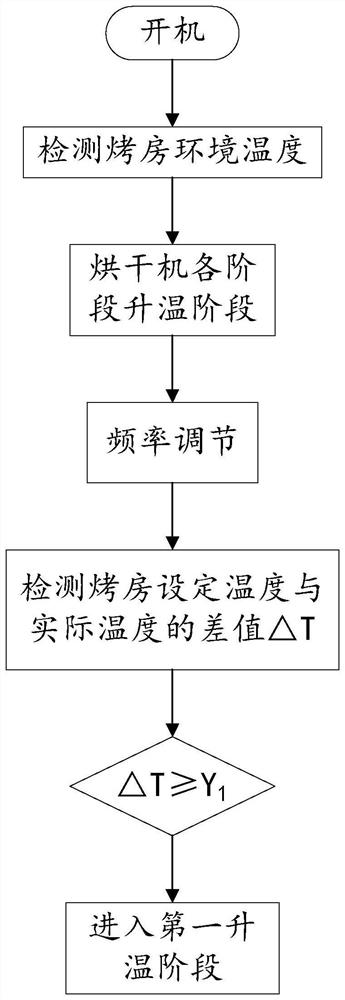

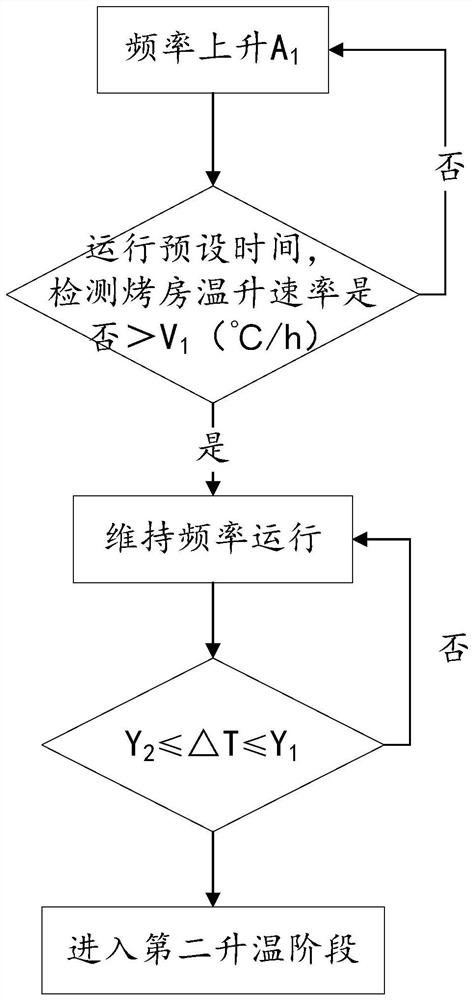

[0066] In step S1, the operating frequency of the compressor is controlled according to the difference between the set temperature of the baking room and the actual temperature, and the temperature rise rate of the baking room is increased in stages by controlling the operating frequency of the compressor, so that the temperature of the baking room can reach the target temperature range smoothly. include:

[0067] According to the obtained ac...

Embodiment 2

[0121] This embodiment provides a heat pump tobacco dryer, including a storage medium and a processor, the storage medium is a non-transitory computer-readable storage medium for storing computer programs, and the processor is used for calling the A computer program in the storage medium, when the computer program runs, executes the control method in Embodiment 1 as an example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com