Temperature control early warning device for high and low voltage equipment

An early warning device, high and low voltage technology, applied in the construction parts of electrical equipment, electrical equipment shells/cabinets/drawers, modification with gaseous coolants, etc., to avoid self-opening and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

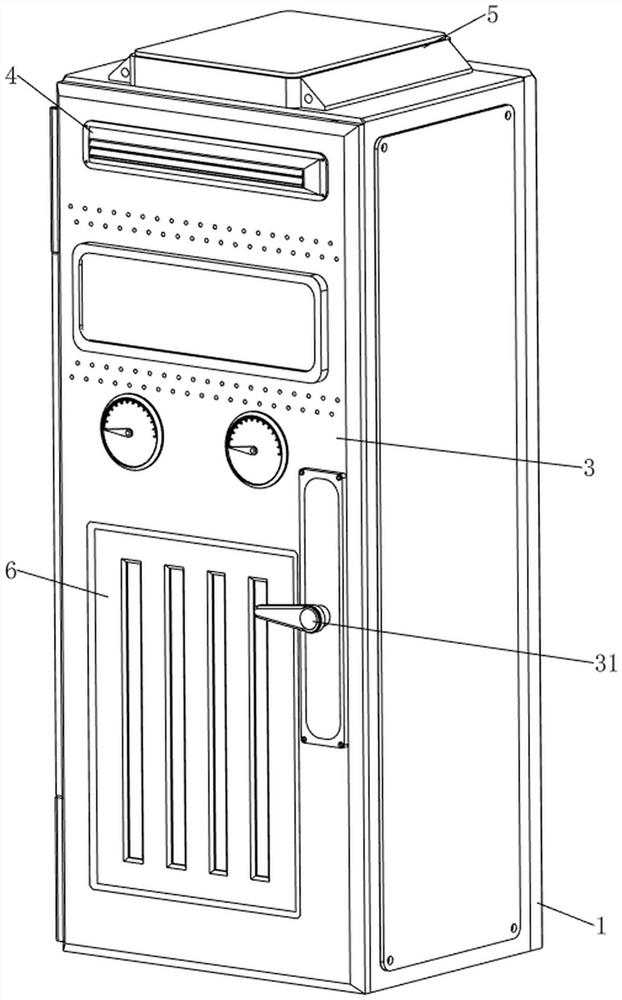

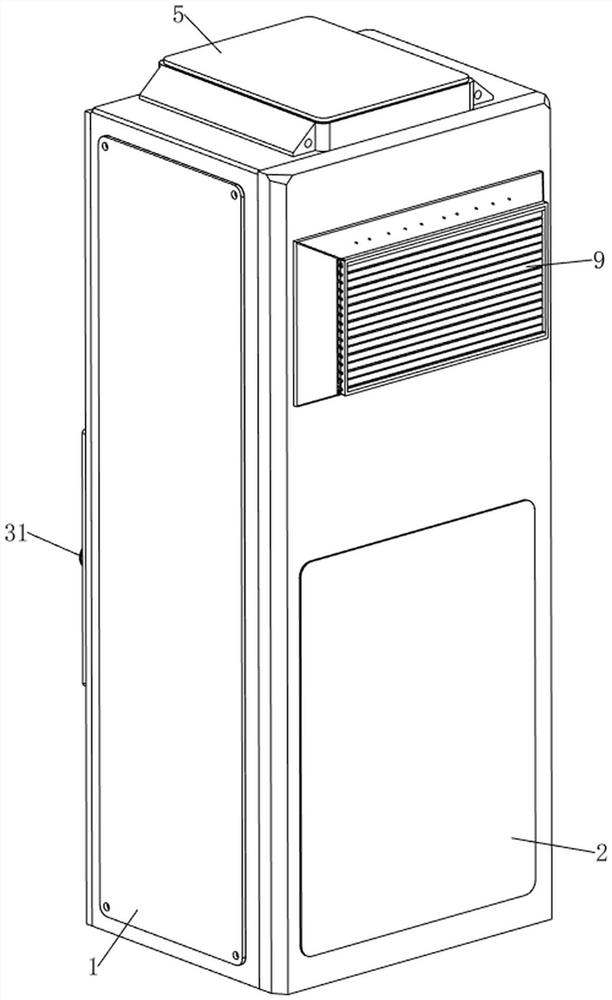

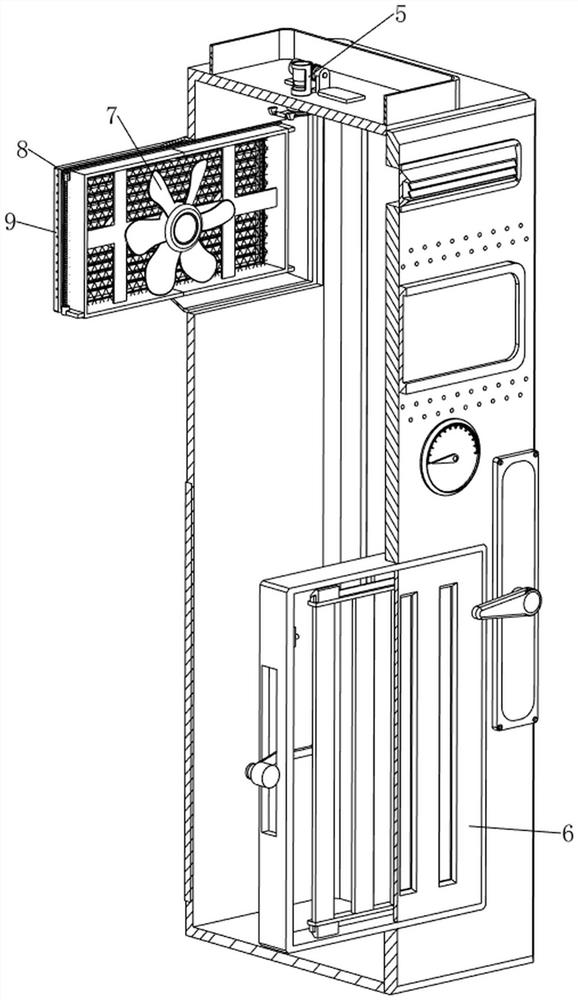

[0082] see figure 1 , figure 2 , image 3 and Figure 4 , a temperature control early warning device for high and low voltage equipment, comprising a cabinet 1, a revolving door 3, a revolving handle 31, a hot air blower 4, a detection mechanism 5, a ventilation mechanism 7 and a sliding mechanism 6, and the left front side of the cabinet 1 is hinged with a revolving door 3, Turning door 3 is used for closing cabinet 1, and turning door 3 front portion right lower side is connected with turning handle 31 in a rotating manner, and turning door 3 top is provided with hot air blower 4, and casing 1 top is provided with detection mechanism 5, and detection mechanism 5 is used for The internal temperature of the cabinet 1 is detected, and the lower side of the revolving door 3 is provided with a sliding mechanism 6. The sliding mechanism 6 facilitates the discharge of hot air inside the cabinet 1. The upper side of the rear of the cabinet 1 is provided with a ventilation mechani...

Embodiment 2

[0088] On the basis of Example 1, please refer to image 3 , Figure 11 and Figure 12 , also includes a cleaning mechanism 8, the cleaning mechanism 8 is used to clean the filter plate 74, the cleaning mechanism 8 includes a fixed block 81, a screw mandrel 82, a third reduction motor 83, a slider 84, a flat belt 85, and a wiping block 86 and the air flow sensor 87, the third fixed plate 72 inside the lower left side is welded with a fixed block 81, the third fixed plate 72 inside the right side is welded with a fixed block 81 symmetrically up and down, and the top of the fixed block 81 on the lower right side is fixed with a third Geared motor 83, the top of the fixed block 81 on the left side and the fixed block 81 on the upper right side are all connected with screw mandrel 82 through bearings, the bottom of the screw mandrel 82 on the right side is connected with the output shaft of the third geared motor 83 through a coupling A flat belt 85 is wound between the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com