Color control electrochromic module

An electrochromic and electrochromic film technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of difficult to form effective changes, single electrochromic color changes, insufficient visual impact, etc., to achieve multiple scenes The effect of simplifying, simplifying the structure, and beautifying the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

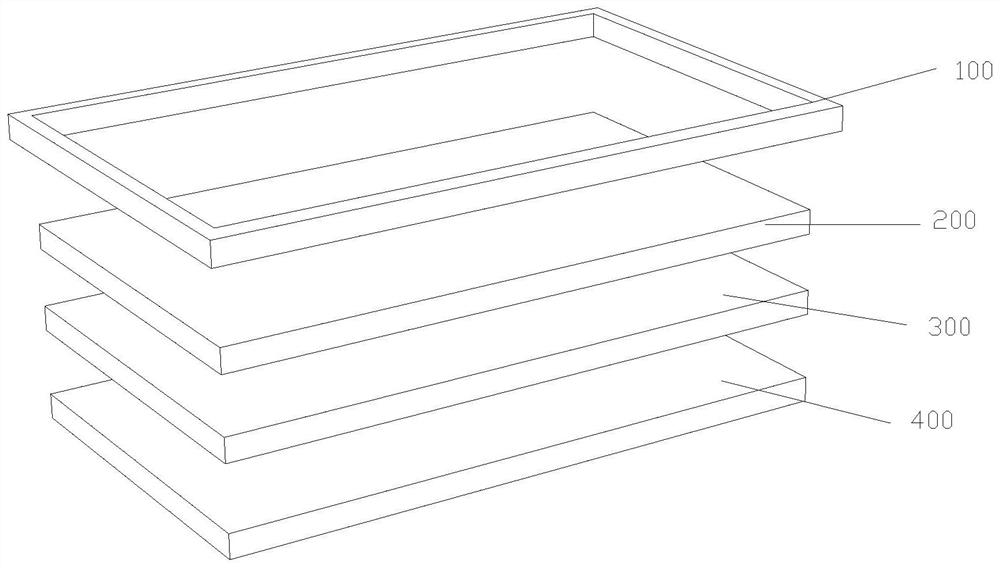

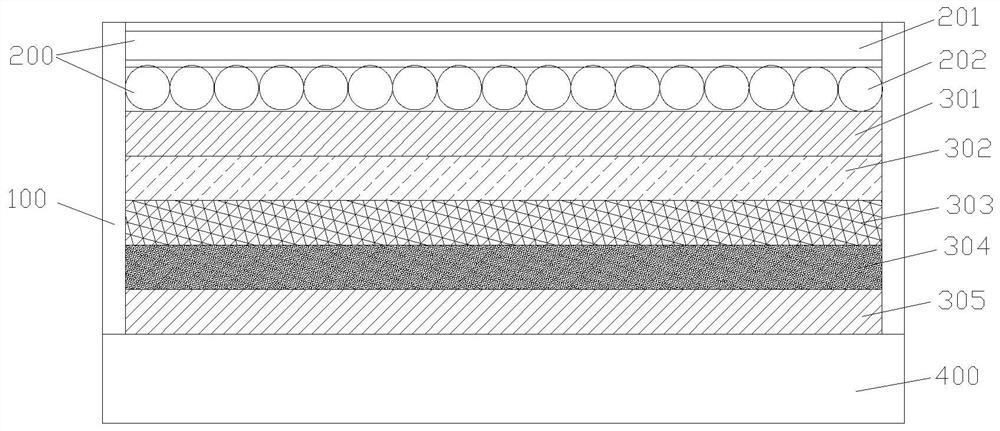

[0050] Such as figure 1 and figure 2 As shown, a color control electrochromic module, the module includes a substrate 400, a module frame 100 bonded to the surface of the substrate 400, and a color filling film 200 laminated in the module frame 100, An electrochromic film 300, wherein the electrochromic film 300 is attached to the surface of the substrate 400, and the color filling film 200 is attached to the other side of the electrochromic film 300. When the electrochromic film 300 is in a transparent state, the entire Modules are transparent.

[0051] Further, the module frame 100 is a frame structure, and the inside of the module frame 100 is installed with a micro-LED light strip. Three primary colors, so as to realize the change of color.

[0052] Further, the inside of the module frame 100 is provided with wiring, and the wiring includes the wiring of the electrochromic film 300 and the wiring of the micro LED, wherein the wiring position of the electrochromic film ...

Embodiment 2

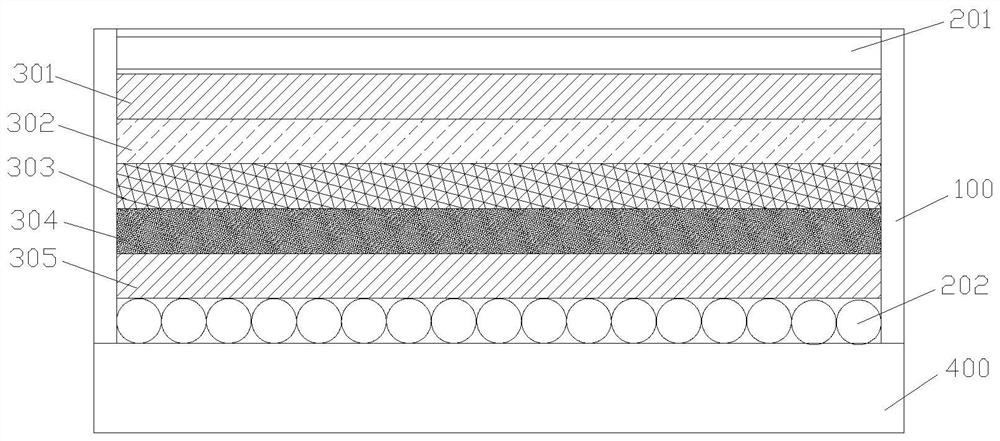

[0058] Such as figure 1 and image 3 As shown, a color control electrochromic module, the module includes a substrate 400, a module frame 100 bonded to the surface of the substrate 400, and a color filling film 200 laminated in the module frame 100, The electrochromic film 300, wherein the second filling layer 202 is attached to the surface of the substrate 400, and the color filling film 200 is split and attached to the upper and lower surfaces of the electrochromic film 300. When the electrochromic film 300 is in In the transparent state, the entire module is in a transparent state.

[0059] Further, the module frame 100 is a frame structure, and the inside of the module frame 100 is installed with a micro-LED light strip. Three primary colors, so as to realize the color change, and the micro LED light strips are set in layers.

[0060] Further, the inside of the module frame 100 is provided with wiring, and the wiring includes the wiring of the electrochromic film 300 an...

Embodiment 3

[0066] Such as figure 1 and Figure 4 As shown, a color control electrochromic module, the module includes a substrate 400, a module frame 100 bonded to the surface of the substrate 400, and a color filling film 200 laminated in the module frame 100, An electrochromic film 300, wherein the color filling film 200 is attached to the surface of the substrate 400, and the electrochromic film 300 is attached to the other side of the color filling film 200. When the electrochromic film 300 is in a transparent state, the entire mold Groups are transparent.

[0067] Further, the module frame 100 is a frame structure, and the inside of the module frame 100 is installed with a micro-LED light strip. Three primary colors, so as to realize the change of color.

[0068] Further, the inside of the module frame 100 is provided with wiring, and the wiring includes the wiring of the electrochromic film 300 and the wiring of the micro LED, wherein the wiring position of the electrochromic fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com