Spraying jig for membrane electrode of proton exchange membrane fuel cell

A proton exchange membrane and fuel cell membrane technology, which is applied to fuel cell parts, fuel cells, circuits, etc., can solve the problem of taking a lot of time, avoid the time for secondary adhesive tape, avoid oven heating time, The effect of improving spray efficiency and spray quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

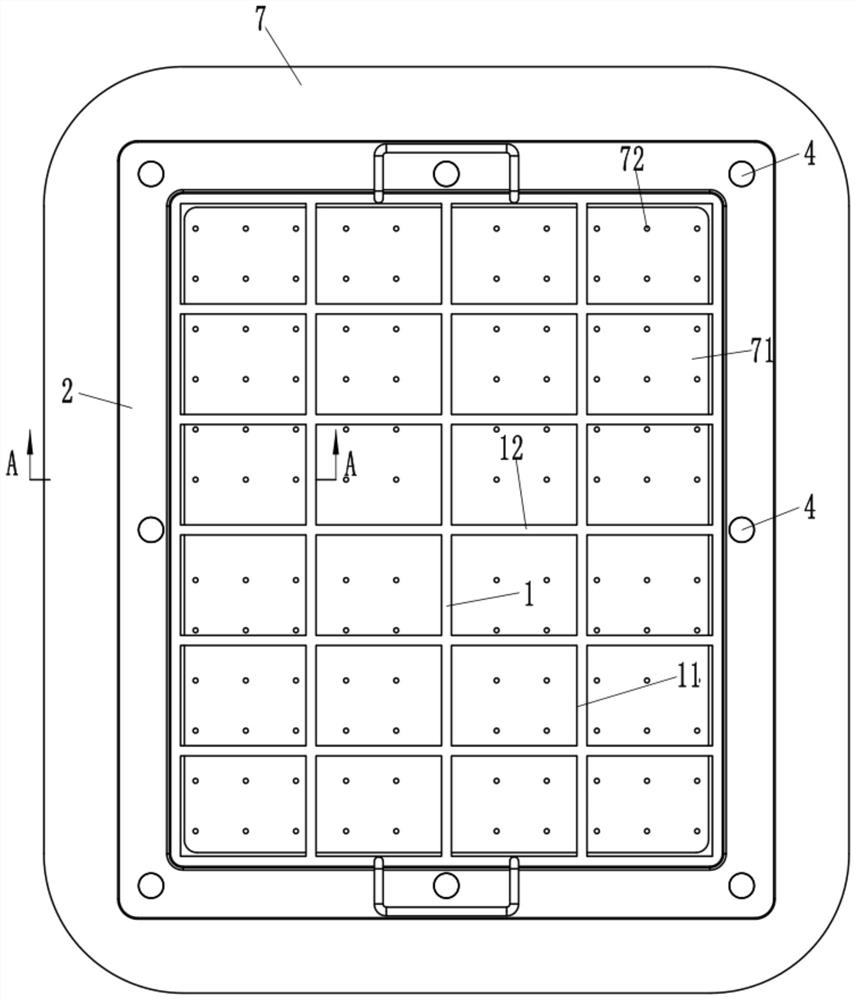

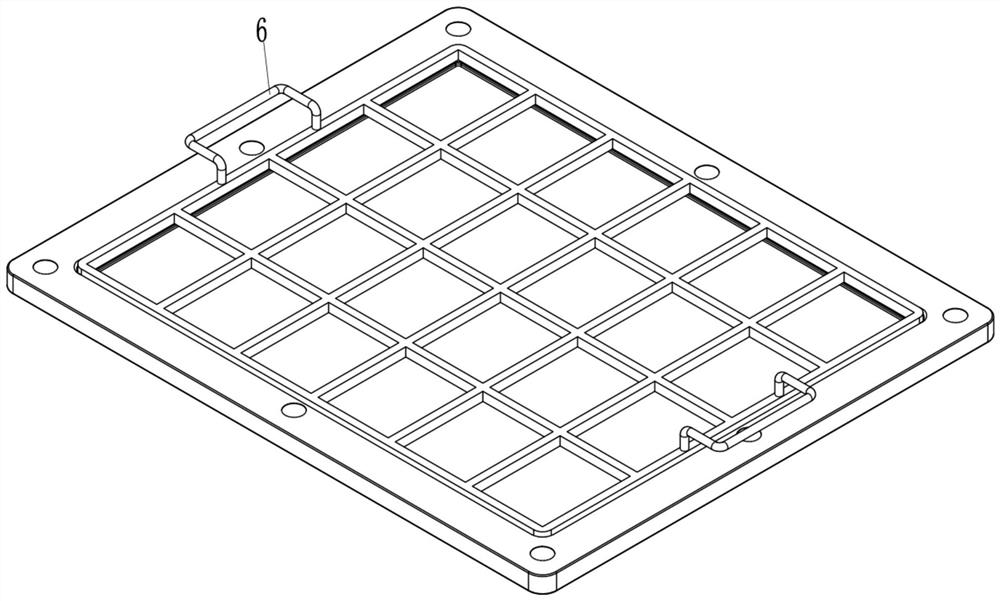

[0030] Examples, see e.g. Figure 1 to Figure 8 Shown, a kind of spraying fixture that is used for the membrane electrode of proton exchange membrane fuel cell comprises the first frame 2 and the second frame 3 that are rectangular spraying spacer frame 1 and up and down setting; Described spraying spacer frame 1 is shaped as A plurality of first spacer strips 11 linearly and uniformly distributed in the left and right directions and a plurality of second spacer strips 12 linearly and uniformly distributed in the up and down direction;

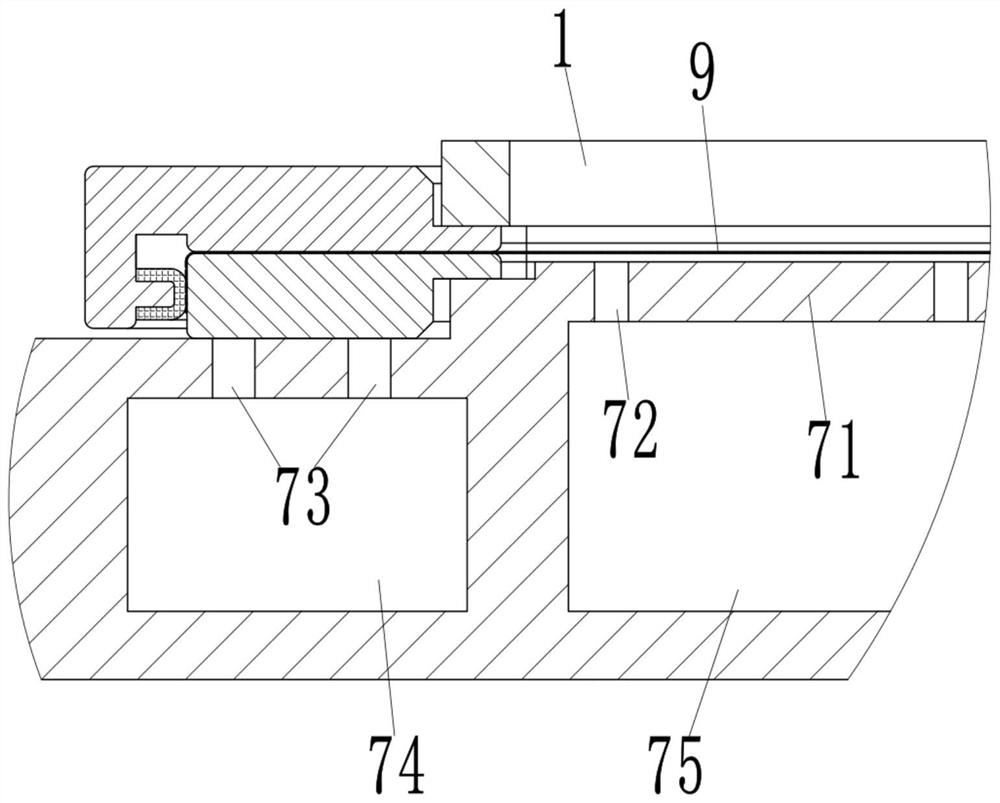

[0031] The middle part of the first frame 2 is formed with a first rectangular step through hole 21, and the middle part of the second frame 3 is formed with a second rectangular step through hole 31. The proton exchange membrane 9 is clamped in the small part of the first rectangular step through hole 21. Between the end face of the end hole and the end face of the small end hole of the second rectangular step through hole 31;

[0032] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com