Mobile industrial sewage water quality detection equipment

A technology for industrial sewage and water quality testing, applied in testing water, material testing products, cleaning methods and utensils, etc., can solve the problems of incomplete and reliable testing data, low testing accuracy, and small testing range, to improve testing convenience, Improve accuracy, improve cleaning efficiency and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

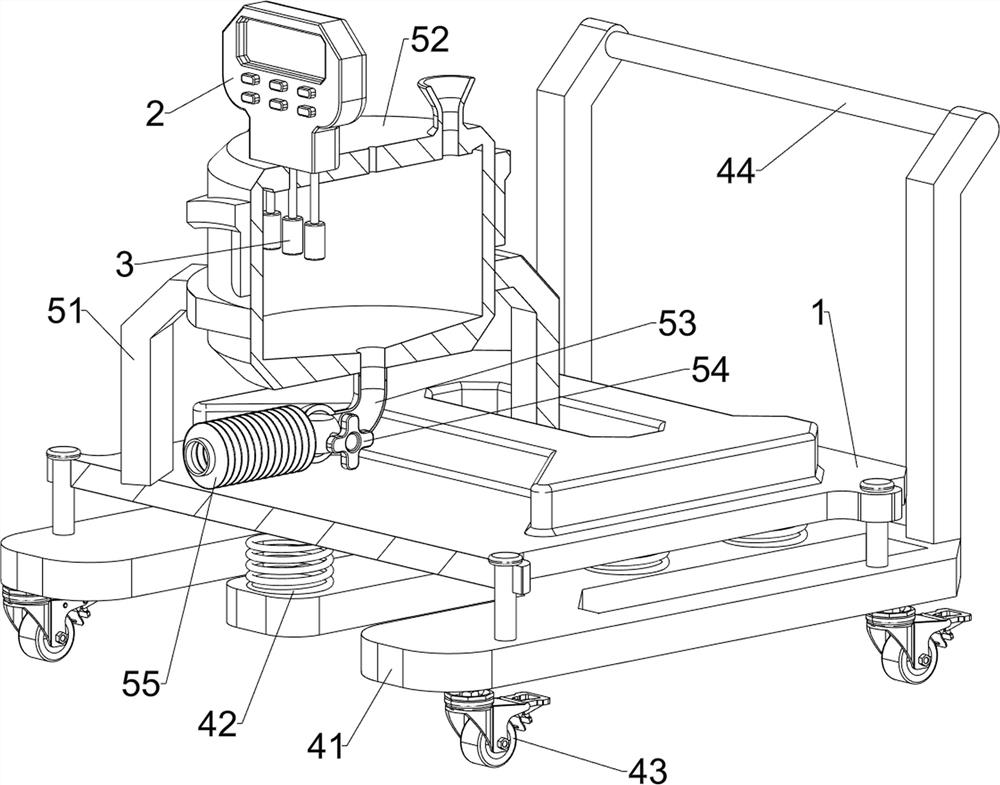

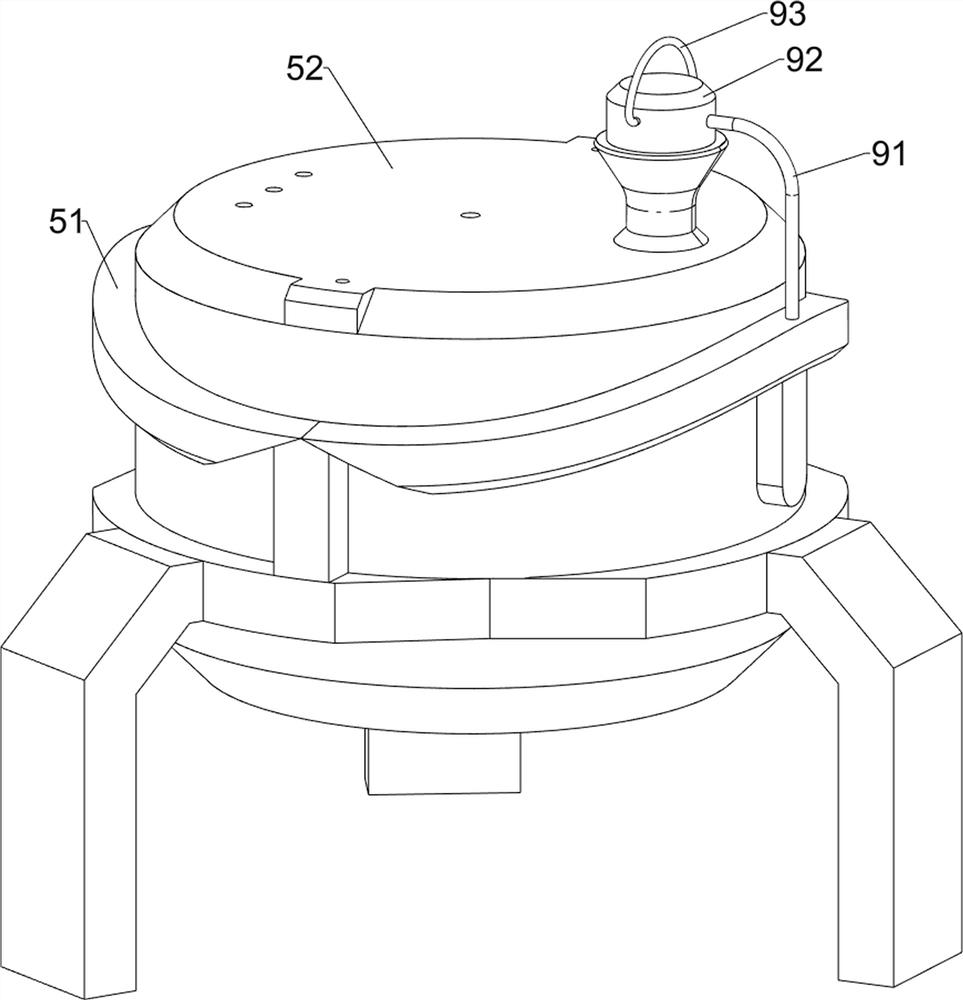

[0024] A mobile industrial sewage water quality detection equipment, such as figure 1 and figure 2 As shown, it includes a first support plate 1, a detector 2, a detection rod 3, a moving assembly 4 and a charging assembly 5, the first supporting plate 1 is provided with a moving assembly 4, and the first supporting plate 1 is provided with a charging assembly 5. The charging assembly 5 is equipped with a detector 2, and the charging assembly 5 is provided with a detection rod 3, and the detector 2 and the detection rod 3 are connected.

[0025] First, people push the mobile component 4, push the first support plate 1 to the side of the sewage ditch, pour the sewage to be detected into the charging component 5, the sewage is in contact with the detection rod 3, and people observe the heavy metal impurity content in the sewage through the detector 2 After the detection is completed, the sewage can be discharged out of the charging assembly 5, so as to achieve the effect of im...

Embodiment 2

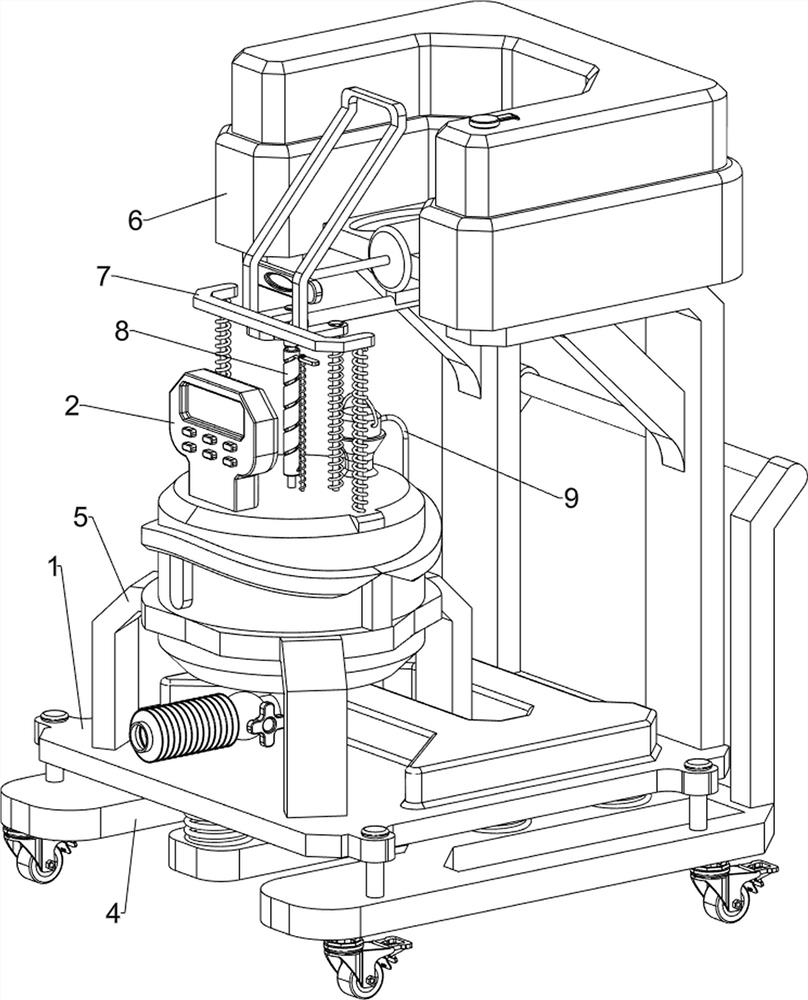

[0030] On the basis of Example 1, such as Figure 3-Figure 5 Shown, also include water spray assembly 6, water spray assembly 6 includes support bar 61, water tank 62, piston cylinder 63, piston rod 64, second spring 65, first water pipe 66, second water pipe 67, shower nozzle 68 and Dustproof cover 69, first support plate 1 top rear side is symmetrically provided with support rod 61, is provided with water tank 62 between support rod 61 tops, is provided with piston cylinder 63 on water tank 62, is provided with piston rod slidingly on piston cylinder 63 64, the second spring 65 is connected between the piston cylinder 63 and the piston rod 64, the second spring 65 is sleeved on the piston rod 64, the rear side of the piston cylinder 63 is provided with a first water pipe 66, and the first water pipe 66 is rotatably provided with The second water pipe 67 is rotatably connected with the charging tank 52 , the bottom of the second water pipe 67 is provided with a nozzle 68 , an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap