Image-based overhead cable icing thickness detection method and device

An overhead cable and ice-covering thickness technology, applied in the field of power transmission and distribution, can solve the problems of broken towers, circuit interruptions, frost, ice and icicles, etc., to prevent surface icing and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Following embodiments of the present invention through specific specific examples and in conjunction with the accompanying drawings, those skilled in the art may be disclosed by the contents of the present specification can easily understand other advantages and efficacy of the present invention. The present invention may also be implemented or applied by other specific examples, the details of the present specification may also be based on different views and applications, without deviating from the spirit of the present invention to carry out various modifications and changes.

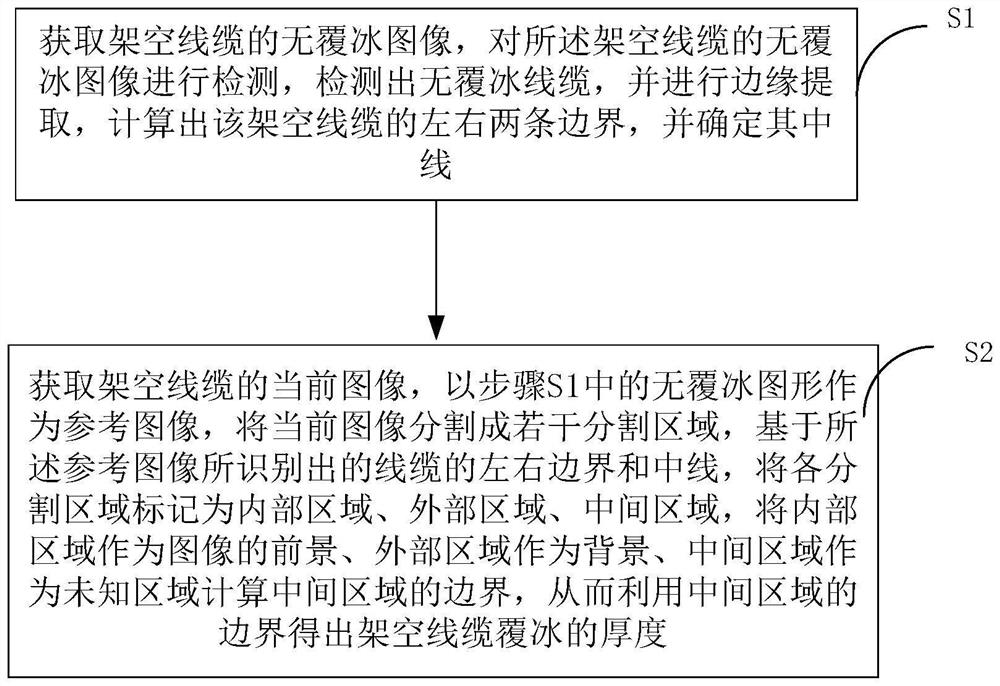

[0043] Figure 1 Step flowchart of an image-based overhead cable icing thickness detection method of the present invention. as Figure 1 As shown, the present invention is an image-based overhead cable icing thickness detection method, comprising the following steps:

[0044] Step S1, to obtain the uniclaced image of the overhead cable, the icing-free image of the overhead cable is detected, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com