Automatic ash removal device applied to charging module

A technology for automatic dust cleaning and charging modules, which is applied in transportation and packaging, separation methods, and separation of dispersed particles. It can solve the problems of high maintenance costs, manual maintenance of cleaning filter screens, and low efficiency, so as to reduce maintenance costs and improve work. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

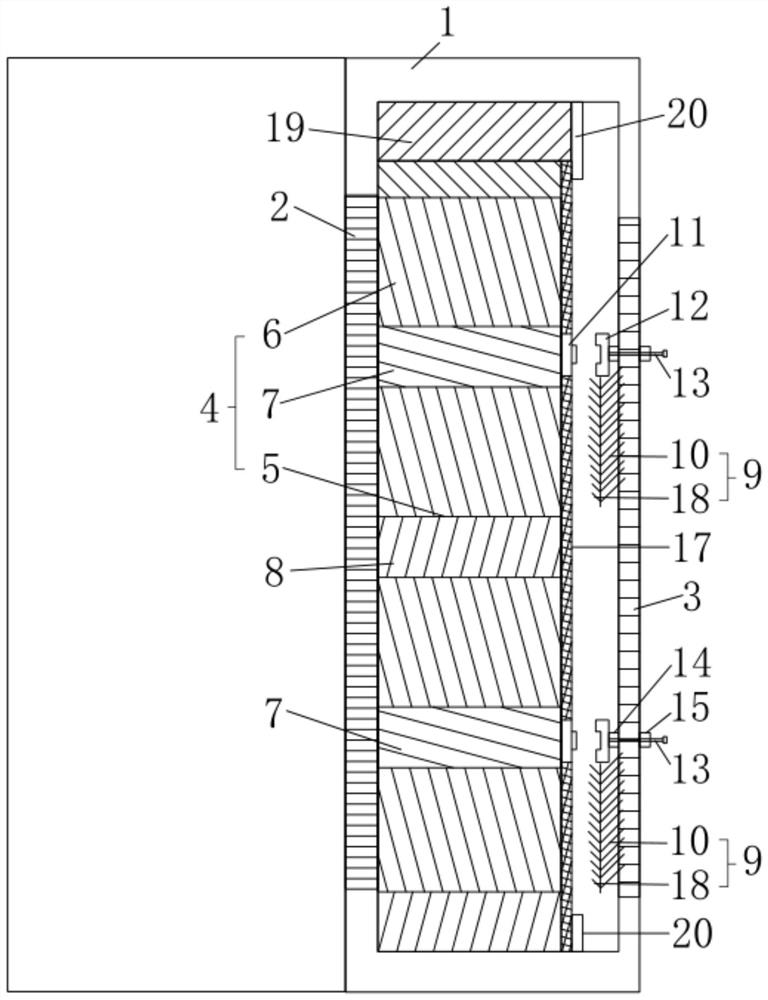

[0065] An automatic dust removal structure applied to the charging module, such as figure 1 As shown, it includes a chassis shell 1, an air duct opening 2 and a filter screen 3 arranged on opposite sides of the chassis shell 1, a heat dissipation structure, and an automatic dust removal structure for cleaning the filter screen 3. The heat dissipation structure and the automatic dust removal structure are installed in the chassis shell 1, the air duct opening 2, the heat dissipation structure, the automatic dust removal structure and the filter screen 3 are arranged in sequence, and the heat dissipation structure and the automatic dust removal structure are detachably connected.

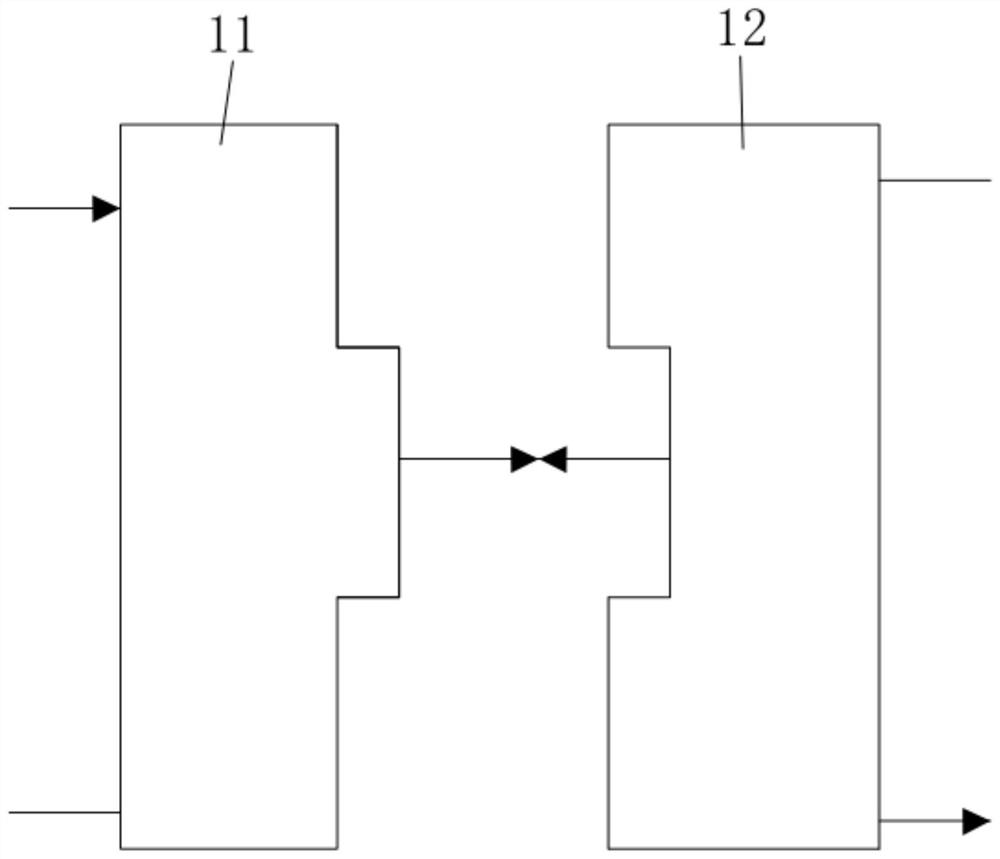

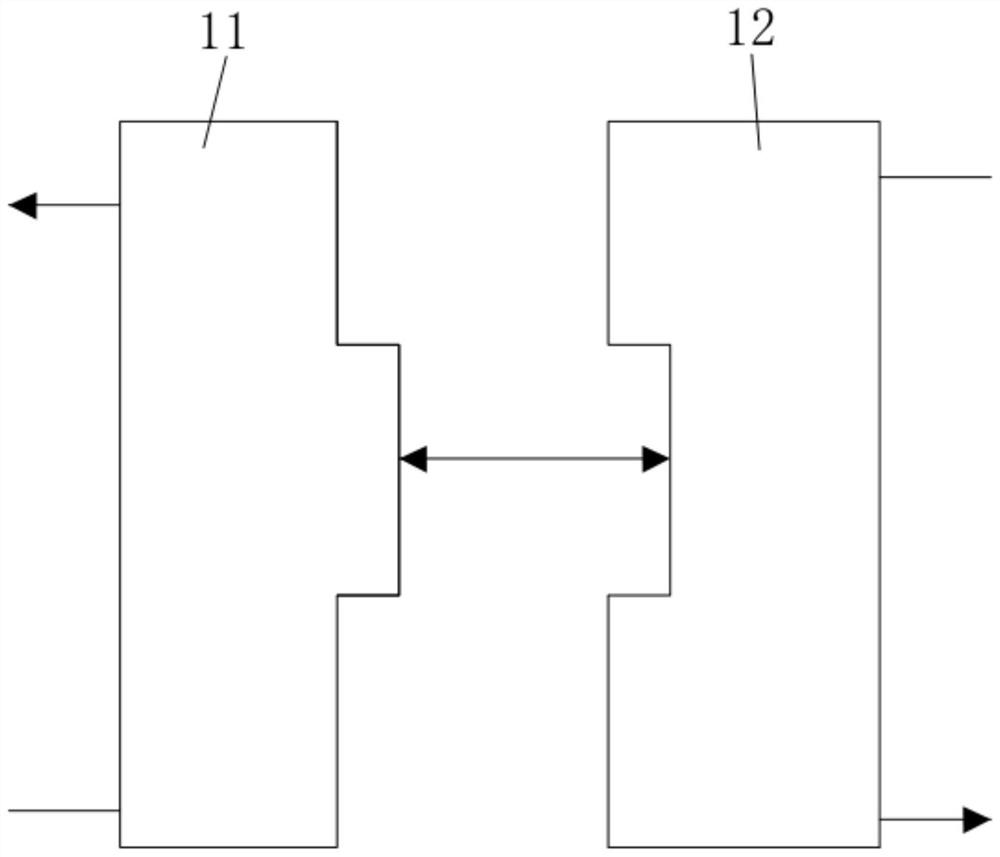

[0066] The heat dissipation structure is installed at one end of the main circuit area of the charging module, and a certain width is reserved between the cooling fan 4 and the filter screen 3 for placing an automatic dust removal structure, wherein the automatic dust removal structure uses the fan m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap