Tool and equipment for machining middle opening of valve body

A valve body and equipment technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of low processing efficiency of the middle mouth of the valve body, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

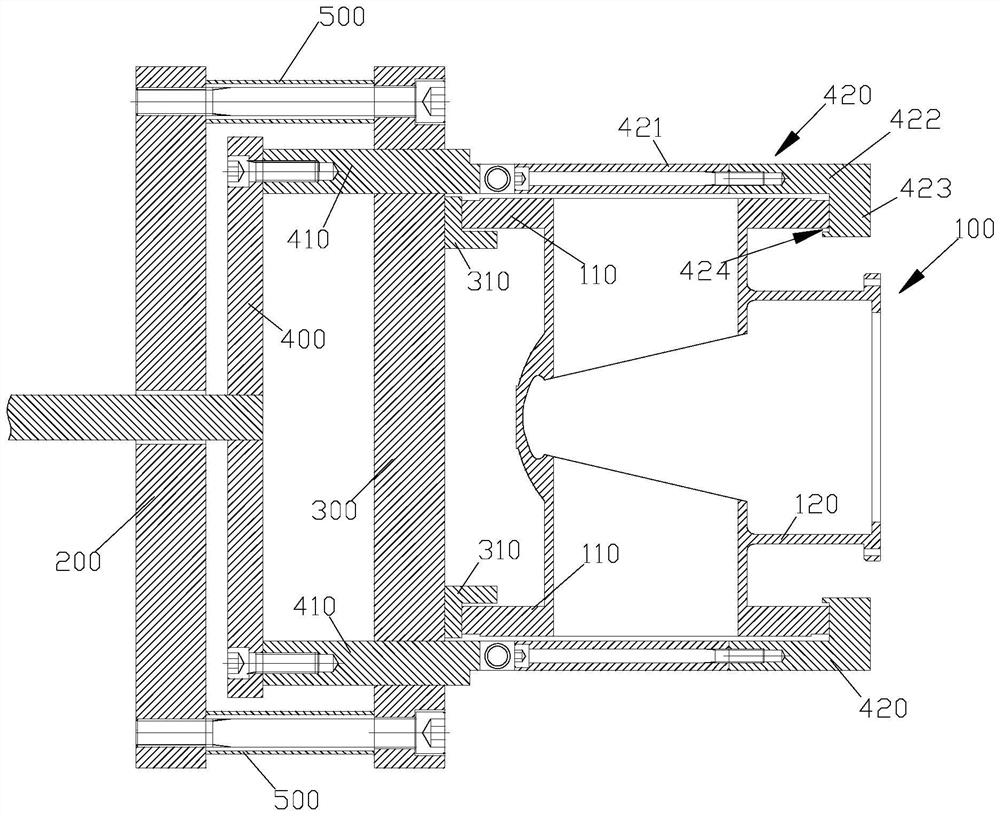

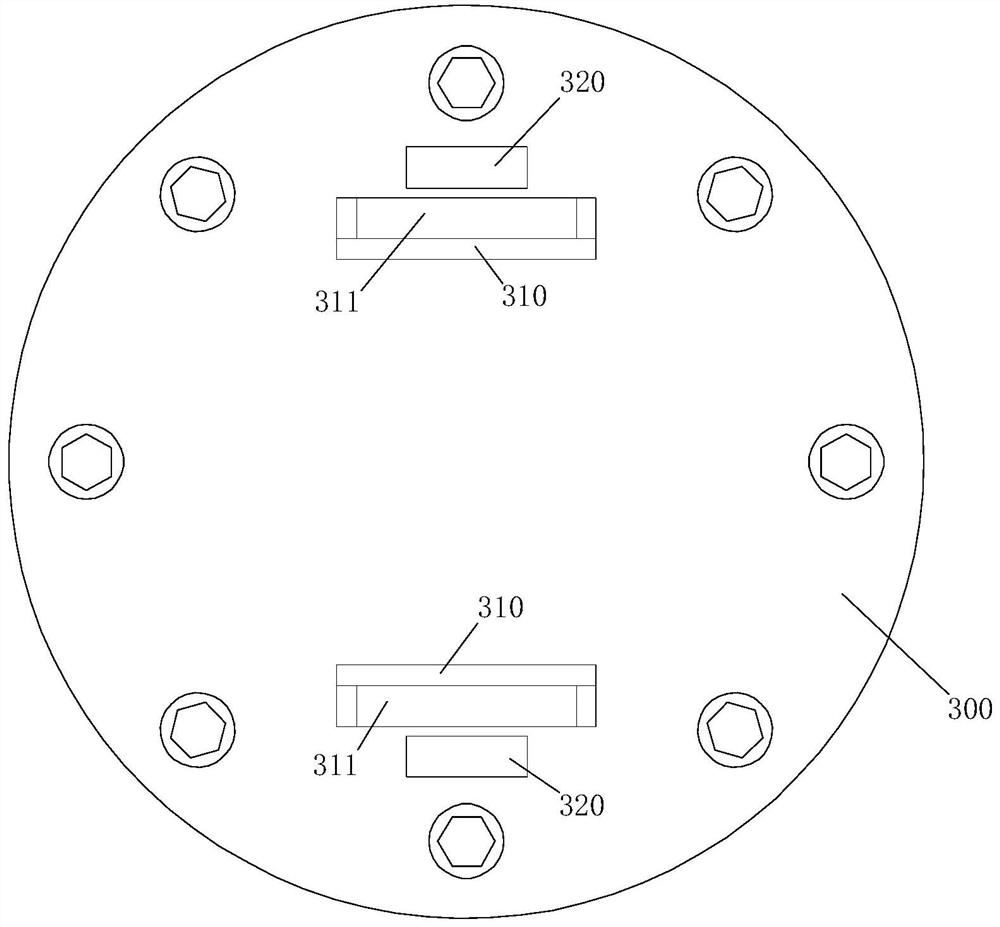

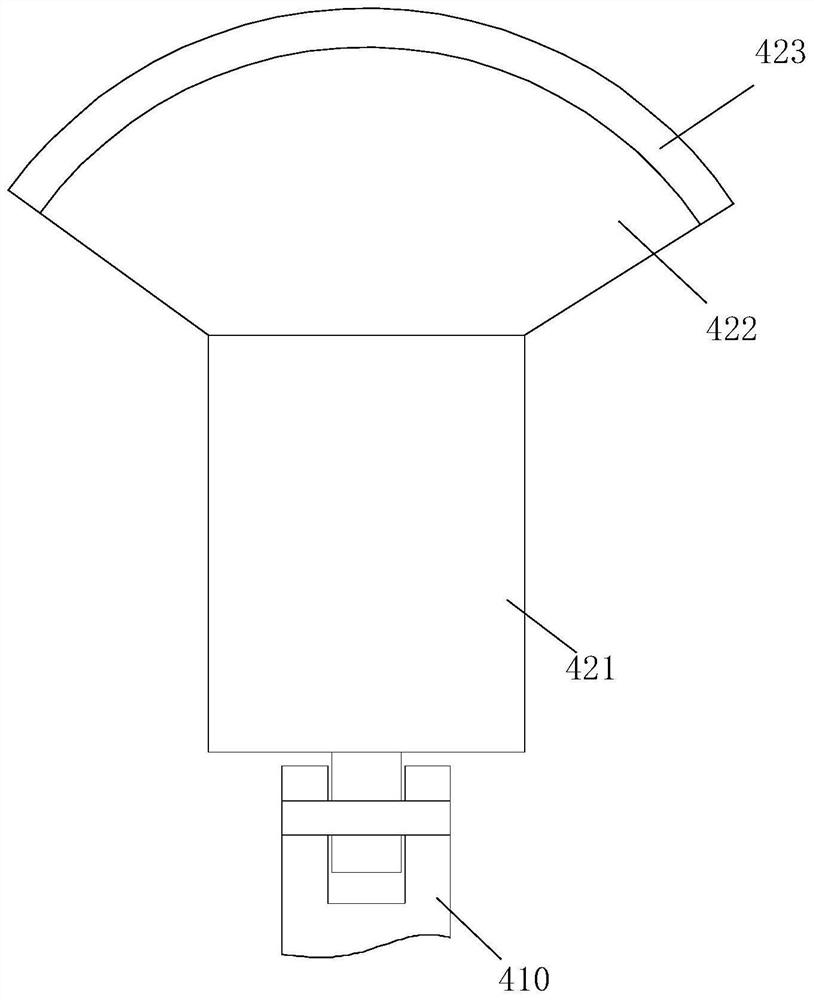

[0045] This embodiment provides a tooling for processing the middle mouth of the valve body. Figure 1 to Figure 4 As shown, it includes a base 200, a positioning part 300, a driving part 400 and a clamping part 420; wherein, the positioning part 300 is arranged on the base 200, a gap is provided between the positioning part 300 and the base 200, and the positioning part 300 is provided with a first positioning part on the side away from the base 200; the driving part 400 is arranged between the base 200 and the positioning part 300, and the driving part 400 is provided with two connecting blocks 410, and the two connecting blocks 410 respectively pass through Over the positioning part 300, and the driving part 400 has a degree of freedom of movement close to or away from the positioning part 300; there are two clamping parts 420, and the two clamping parts 420 are hinged with the two connecting blocks 410 in one-to-one correspondence; the two clamping parts The clamping parts...

Embodiment 2

[0058] This embodiment relates to a tooling for processing the middle mouth of a valve body, which has roughly the same structure as the tooling provided in Embodiment 1, the difference is that, refer to Figure 5 As shown, the tooling of this embodiment also includes a screw 610 and a guide shaft 620; wherein, the screw 610 is rotatably arranged on the positioning member 300, and the screw 610 includes a left-handed section and a right-handed section connected in series; two first positioning One of the blocks 310 is provided with a left-handed threaded hole, and the other is provided with a right-handed threaded hole; the left-handed threaded hole is screwed with the left-handed section, and the right-handed threaded hole is screwed with the right-handed section; the guide shaft 620 is fixed on the positioning member 300 and parallel to the screw rod 610 ; two first positioning blocks 310 are respectively provided with guide holes 350 , and each guide hole 350 is slidably sle...

Embodiment 3

[0065] This embodiment relates to a tooling for processing the middle mouth of a valve body, which has roughly the same structure as the tooling described in Embodiment 1, the difference lies in: refer to Image 6 As shown, in this embodiment, a backing plate 700 is provided in the first arc-shaped groove 311, and the backing plate 700 is supported on the wall surface inside the first arc-shaped groove 311 via an elastic member; the backing plate 700 is used to connect with the corresponding port The inner side of the flange 110 fits together; towards the direction close to the bottom of the first arc-shaped groove 311 , the side of the backing plate 700 for fitting with the port flange 110 includes an inclined guide section 710 and a fitting section 720 in sequence.

[0066] That is to say, in the tooling of this embodiment, after the port flange 110 of the valve body 100 is inserted into the first arc-shaped groove 311, specifically, the backing plate 700 abuts against the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com