Fabricated square ground structure on basement top plate and construction method of fabricated square ground structure

A basement roof and prefabricated technology, applied in basic structure engineering, pavement paved with prefabricated blocks, protective devices, etc., can solve the problems of increasing the load of the basement roof, the difficulty of repairing and making up for leakage points, and the increase of structural cost, etc., to achieve Improve the construction quality, ensure the flatness and stability of the paving, and reduce the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

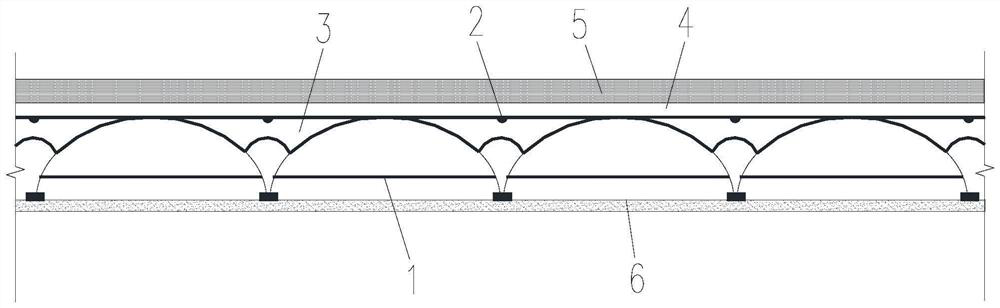

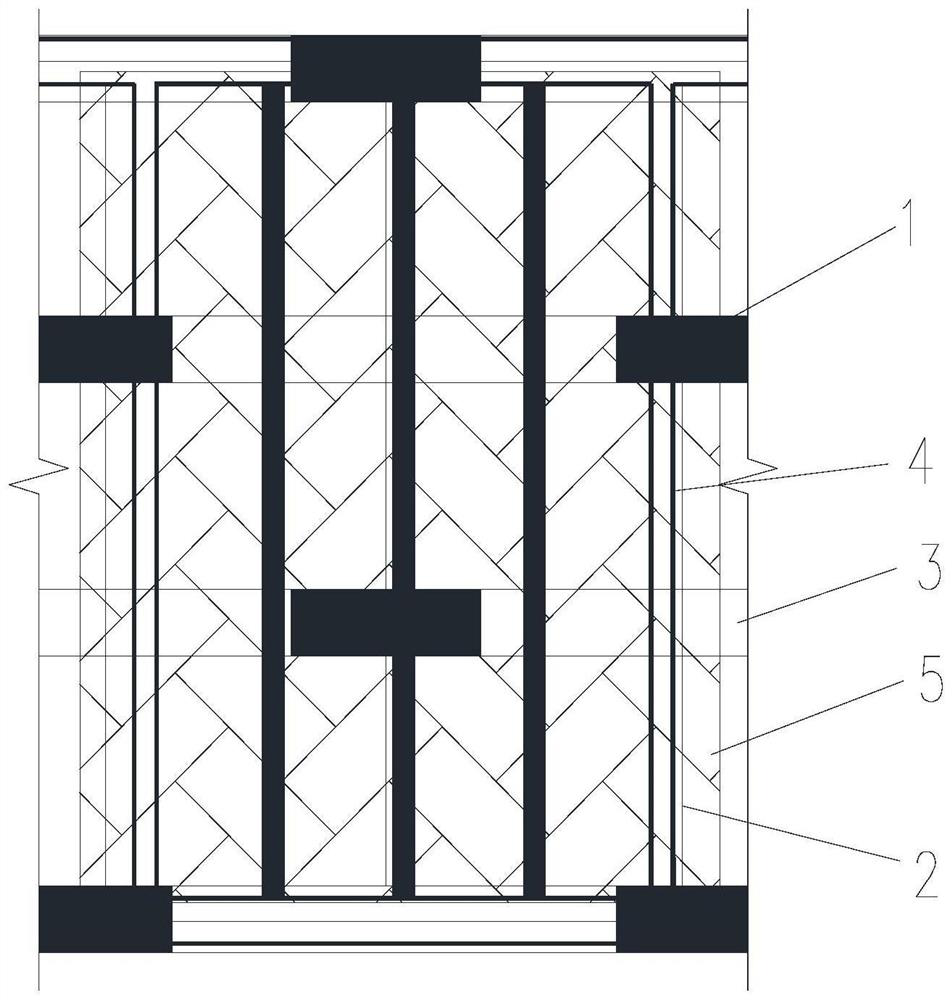

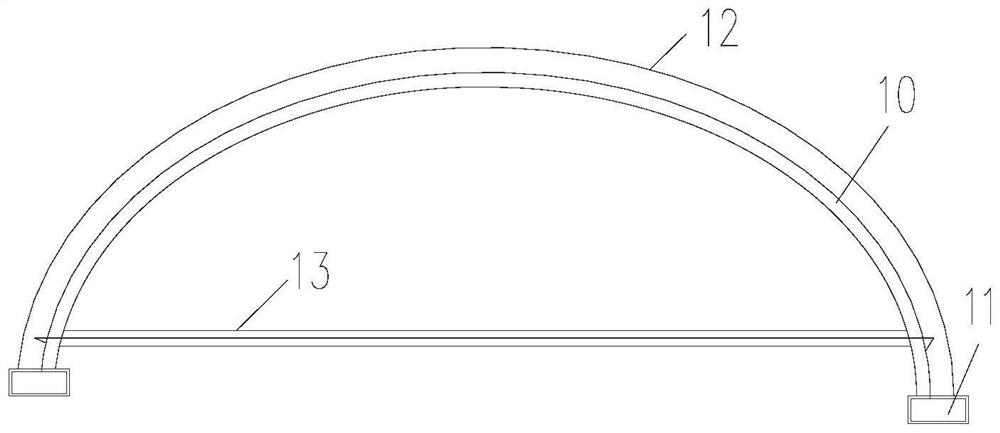

[0038] Please see attached figure 1 And attached figure 2 , a prefabricated square ground structure on the roof of a basement, including an arch assembly 1, a horizontal brace 2, an arch wedge assembly 3, a surface bracket assembly 4 and a surface finish 5; several groups of arch assemblies 1 are sequentially connected to form "One"-shaped structure arch row units, several rows of arch frame row units are respectively distributed on the waterproof protective layer of the basement roof 6; each arch frame assembly 1 of two adjacent rows of arch frame row units is arranged alternately, horizontal support 2 The two ends of the arch wedge assembly 3 are respectively connected to the arch assembly 1 of the two rows of arch row units, and the horizontal brace 2 is vertically arranged with the arch row unit; the bottom of the arch wedge assembly 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com