Cage type impeller and impeller set

An impeller and cage technology, applied in the direction of non-variable pumps, non-volume pumps, lighting and heating equipment, etc., can solve the problems of high energy consumption and large space occupation, and achieve volume reduction, space saving and strength avoidance Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

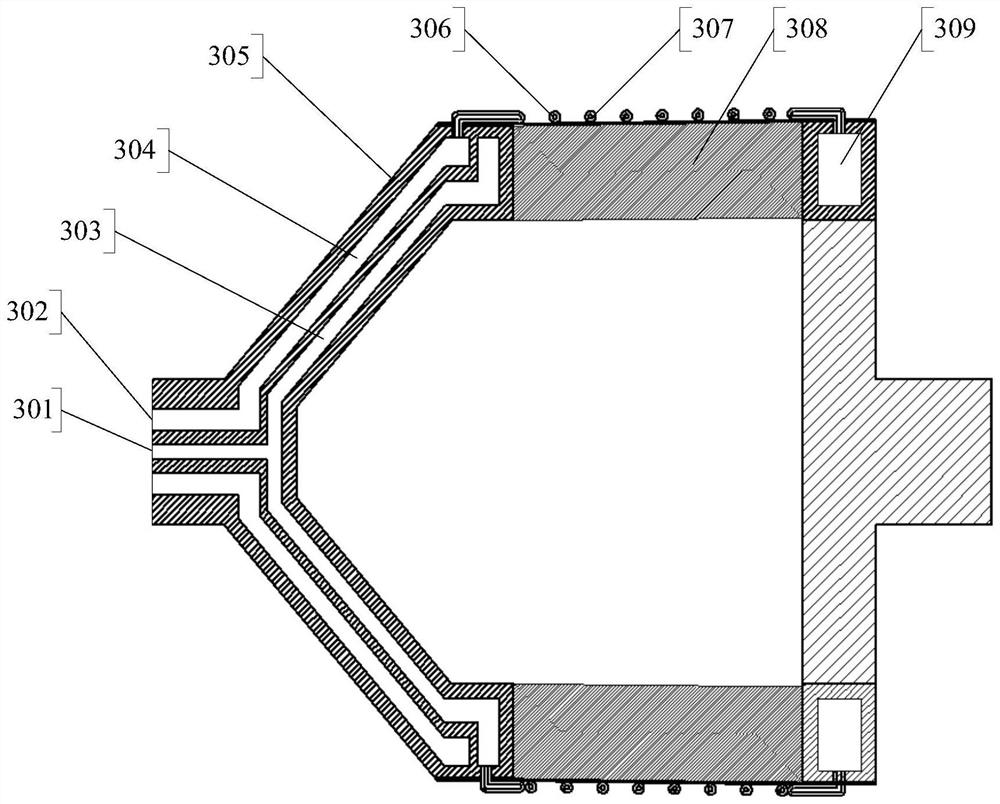

[0040] The technical solutions of the present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

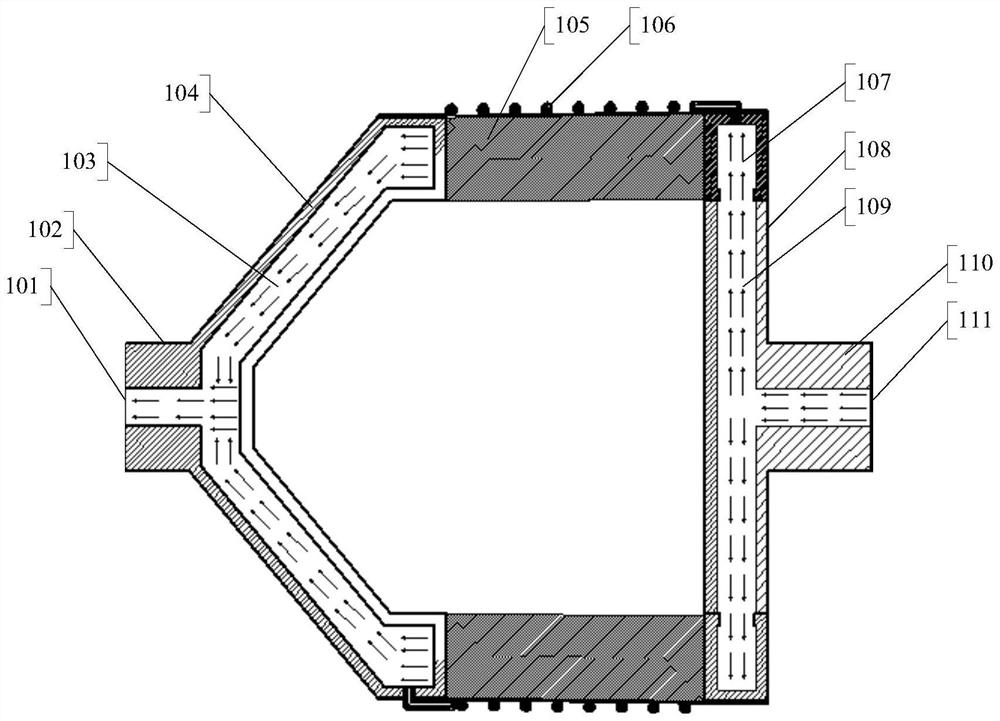

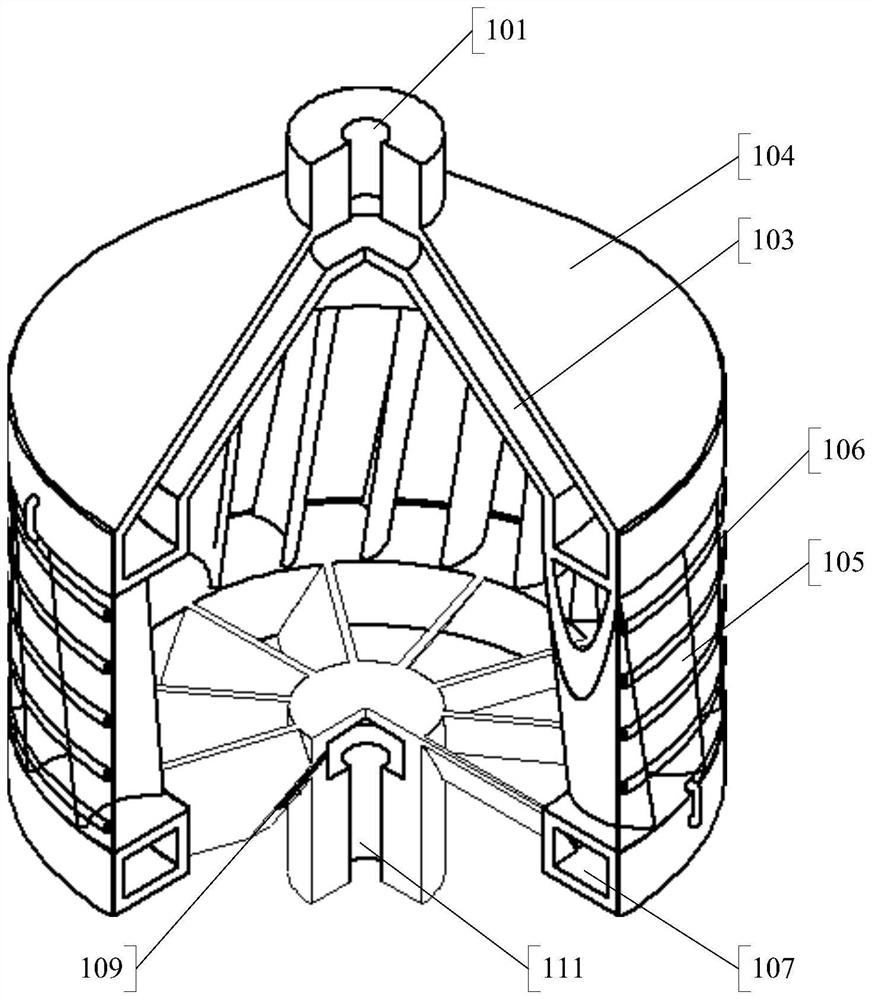

[0041] figure 1 and figure 2 The specific structure of the first embodiment of the present invention is shown. The cage impeller includes a cylindrical impeller main body surrounded by a plurality of elongated main blades 105 . The main body fan blade 105 is arranged on the side wall of the cylindrical impeller main body. At both ends of the impeller body (the two bottom positions of the cylinder) there are first impeller ends ( figure 1 middle right end) and second impeller end ( figure 1 middle left end). The main blade 105 extends from the end of the first impeller to the end of the second impeller. An electric heating tube 106 is provided outside the side wall of the impeller main body. The electric heating tube 106 is spirally wound around the side wall of the impeller body. In other embodiments, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com