Vehicle-mounted camera

A camera and lens technology, applied in the field of vehicle cameras, can solve problems such as accurate identification obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

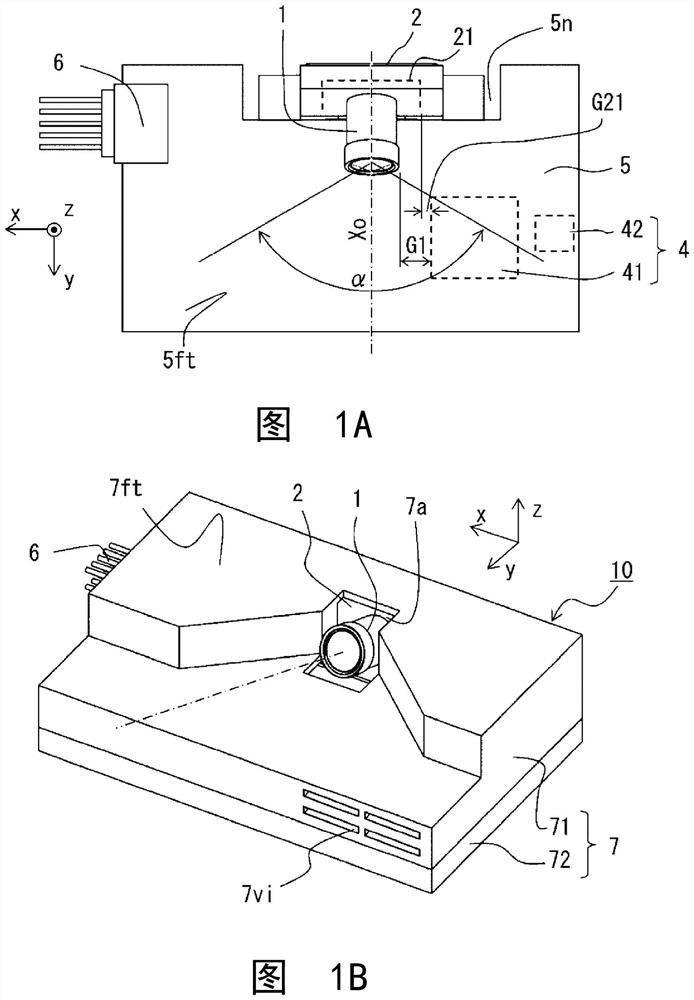

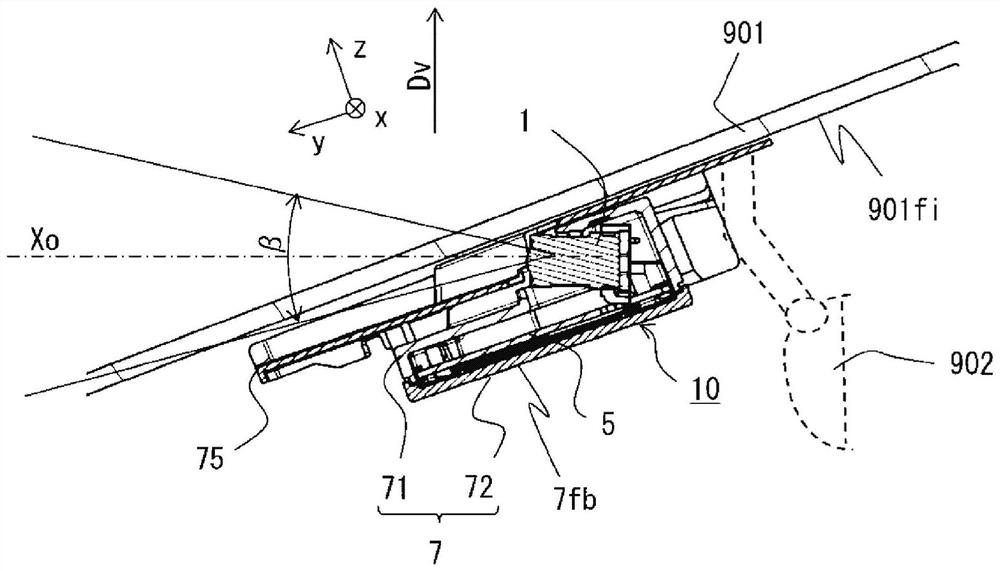

[0023] Figure 1 ~ Figure 4 It is a drawing for explaining the vehicle-mounted camera of Embodiment 1, figure 1 It is a plan view showing the arrangement of main components such as the lens barrel and heat generating components on the circuit board constituting the vehicle-mounted camera ( figure 1 A) and a perspective view of the overall vehicle camera viewed from the upper left front ( figure 1 B), figure 2 It is a schematic cross-sectional view showing the state after the vehicle-mounted camera is mounted on the vehicle, including the optical axis and the vertical line.

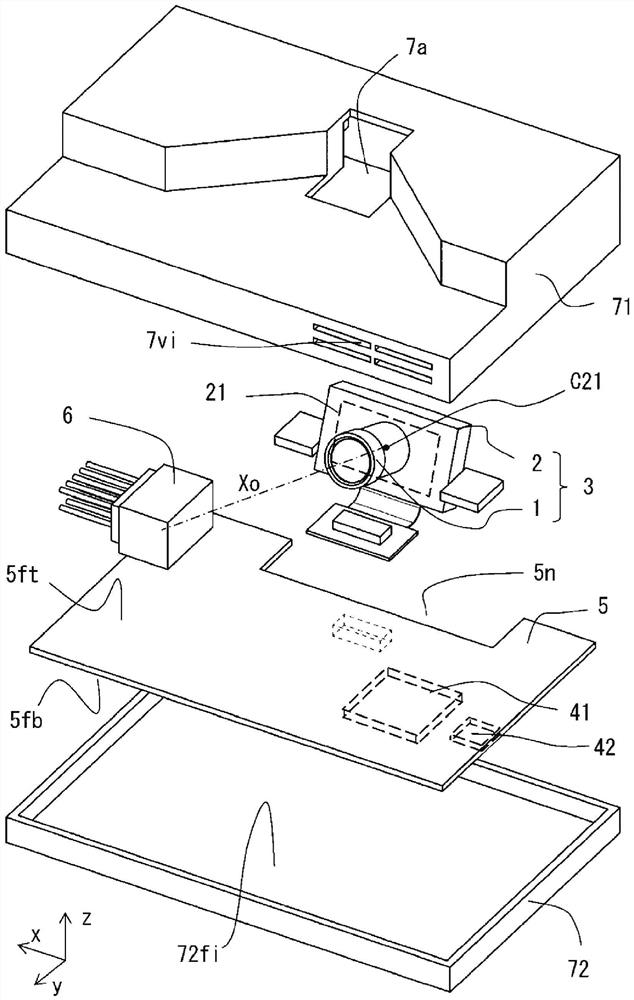

[0024] also, image 3 It is an exploded view showing the state before the camera module and circuit board of the vehicle-mounted camera are installed in the case, Figure 4 It is a perspective view of the inner surface side of the upper case viewed from the lower side ( Figure 4 A) and using figure 1 B Partially cutaway perspective view showing the internal structure when the camera module and ...

Embodiment approach 2

[0065] In the first embodiment described above, there is no particular mention of the surface of the circuit board opposite to the mounting surface of the heat generating component. In this Embodiment 2, the example which provided the heat storage body in the area|region corresponding to the arrangement|positioning area|region of a heat generating component of the surface on the opposite side to the mounting surface of a heat generating component is demonstrated. Figure 7 It is a drawing for explaining the vehicle-mounted camera of the second embodiment, and shows the arrangement of components on the circuit board and is the same as that of the first embodiment. figure 1 The top view corresponding to A ( Figure 7 A) and a partially cutaway perspective view showing the internal structure of the state in which the circuit board is mounted in the upper casing seen from the lower side. In addition, in Figure 7 In B, for the sake of simplification, drawing of some ventilation...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap