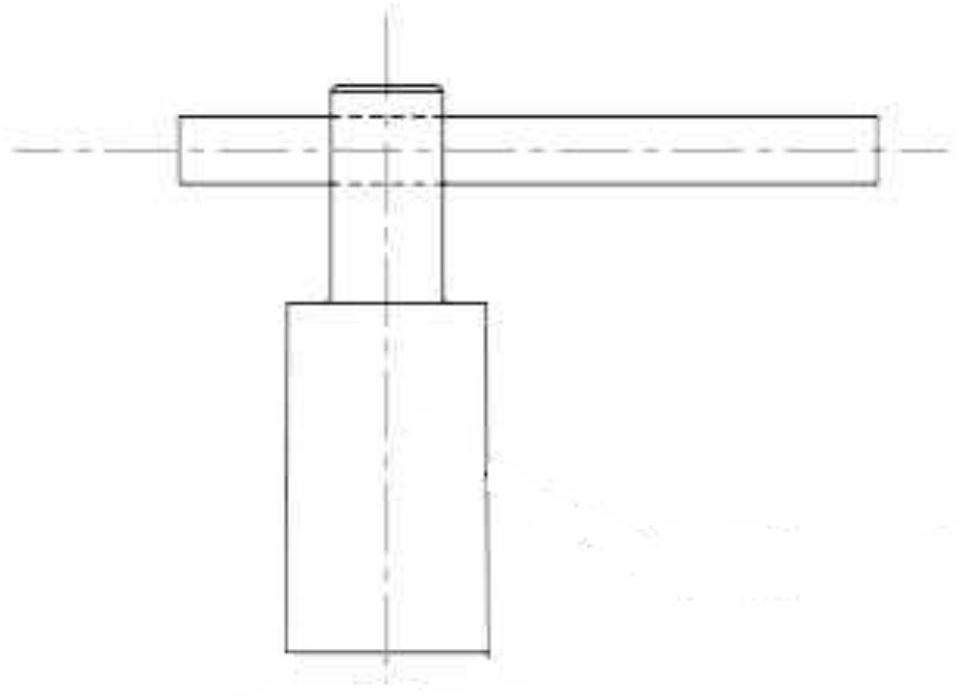

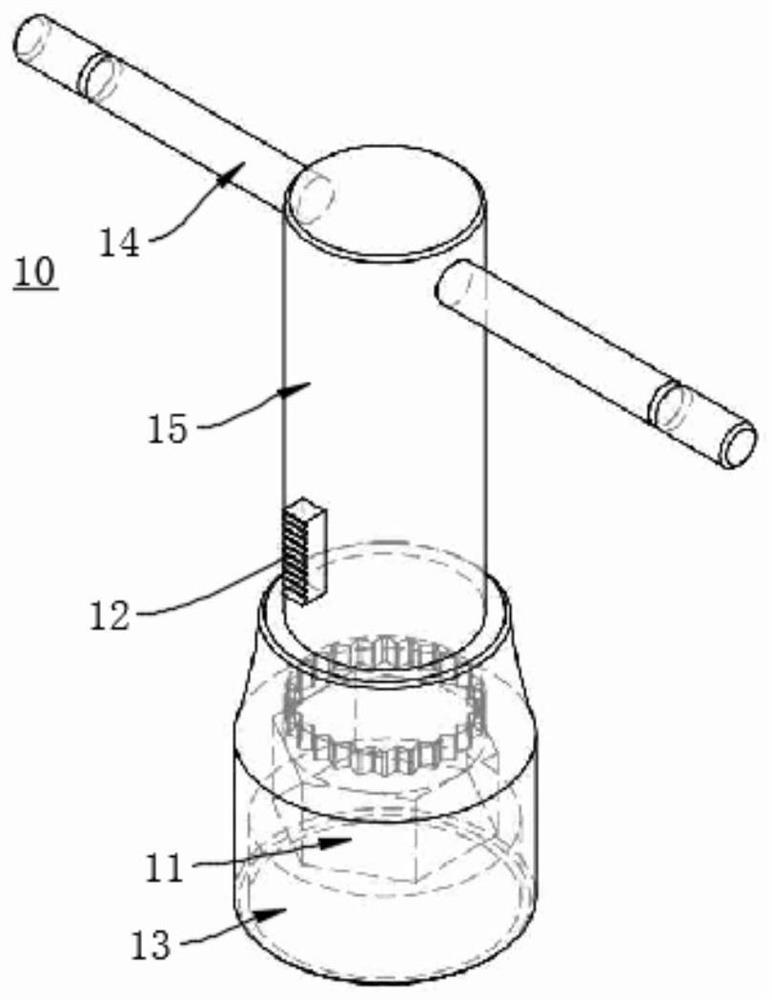

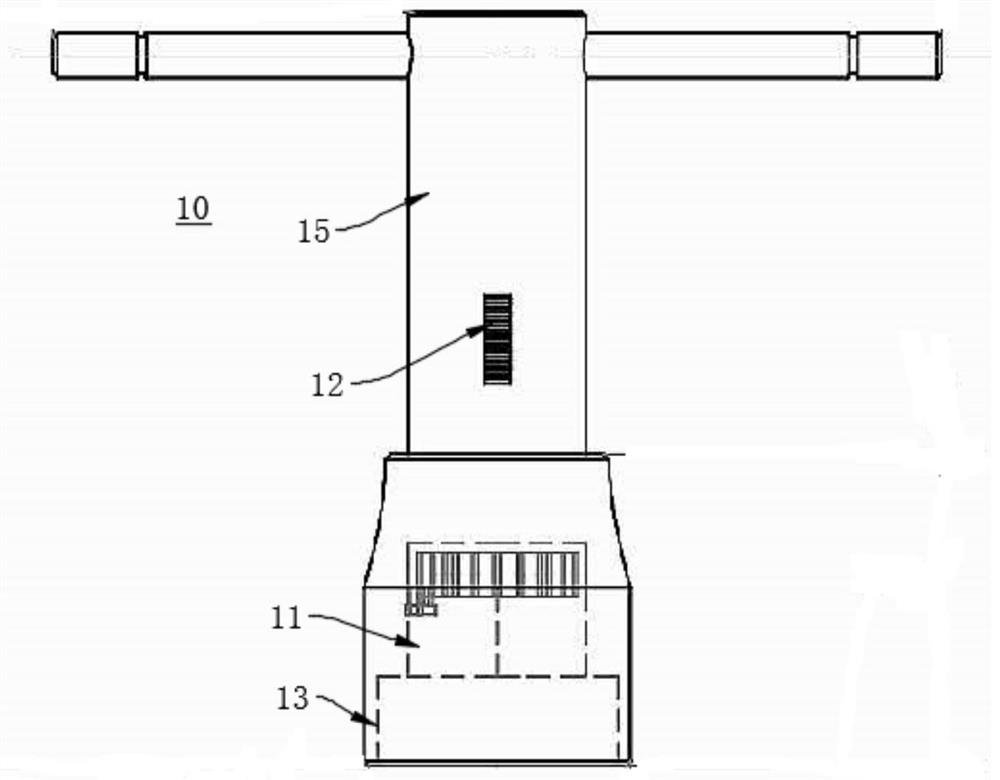

Plug tightening tool

A technology of screw plug and tooling, applied in the field of engine assembly tools, can solve the problems of loss of sealing effect, occurrence of cutting ring, elastic deformation, stretching and extension, etc., and achieve the effect of avoiding water ingress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present application will be further elaborated below in combination with specific embodiments. It should be understood that these specific embodiments are only used to illustrate the present application and not to limit the scope of the present application.

[0025] For the sake of brevity, only certain numerical ranges are specifically disclosed herein. However, any lower limit can be combined with any upper limit to form an unexpressed range; and any lower limit can be combined with any other lower limit to form an unexpressed range, just as any upper limit can be combined with any other upper limit to form an unexpressed range. Furthermore, each individually disclosed point or individual value may serve as a lower or upper limit by itself in combination with any other point or individual value or with other lower or upper limits to form an unexpressly recited range.

[0026] In the description herein, it should be noted that, unless otherwise specified, "above" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com