Dust-removal-free silica gel key screen printing machine

A screen printing machine and silicone technology, which is applied in screen printing machines, printing machines, screen printing, etc., can solve the problems of dirtying the area to be screen printed, damaging the silicone buttons, and cumbersome operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

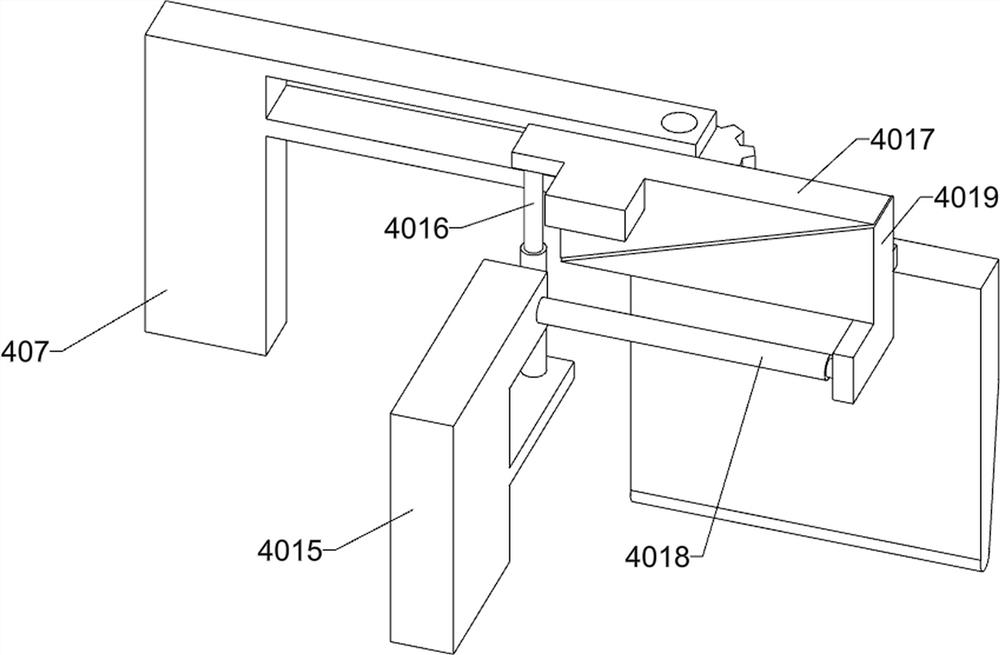

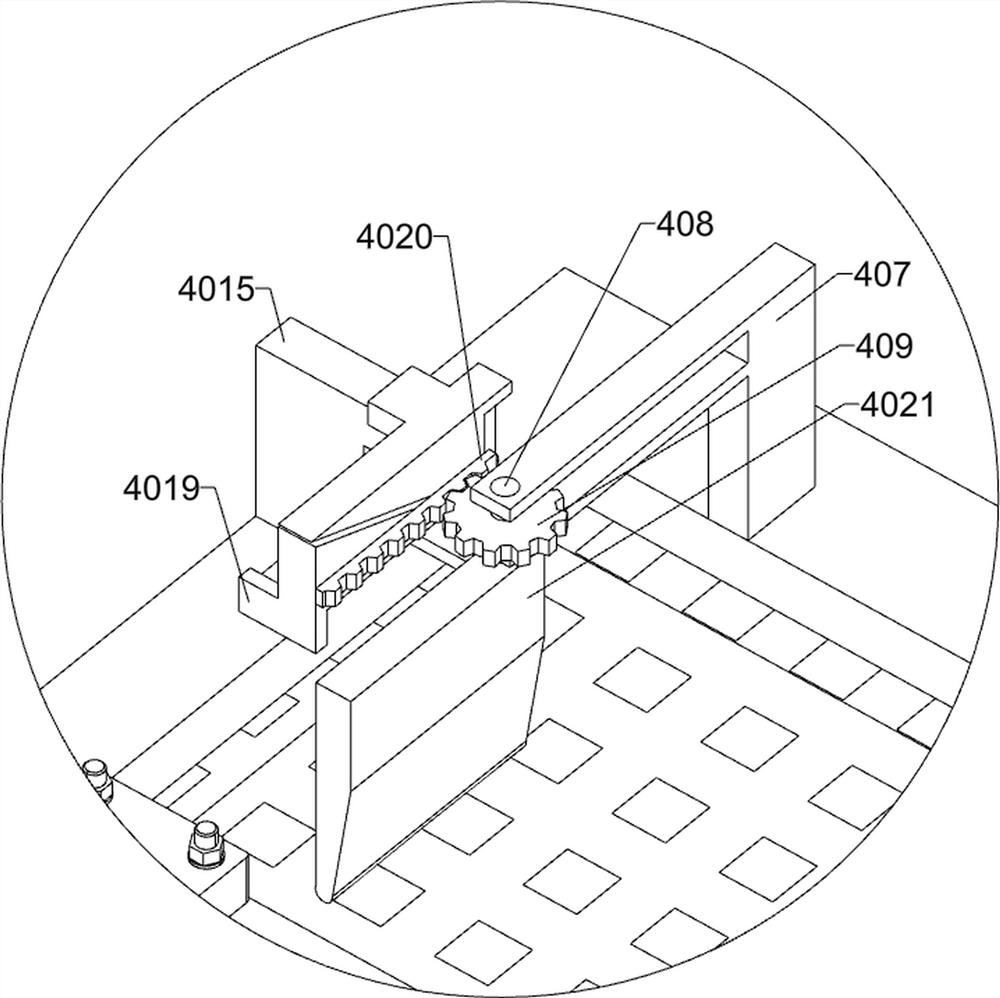

[0032] A dust-free silicone button screen printing machine, such as Figure 1-11 As shown, it includes a bottom frame 1, a first mounting plate 2, a feeding unit, a rolling unit and a silk screen unit; the top of the bottom frame 1 is connected to the first mounting plate 2; unit; the upper left part of the first installation board 2 is connected with a rolling unit; the upper right part of the first installation board 2 is connected with a silk screen unit.

[0033] The feeding unit includes a first electric slide rail 201, a first electric slider 202, a second mounting plate 203, a first motor 204, a first mounting frame 205, a steel plate 206, a second mounting frame 207, and a third mounting frame 208 , the first transmission shaft 209, the first transmission wheel 2010, the second transmission wheel 2011, the second transmission shaft 2012, the third transmission wheel 2013, the fourth transmission wheel 2014, the third transmission shaft 2015, the base 2016, the second m...

Embodiment 2

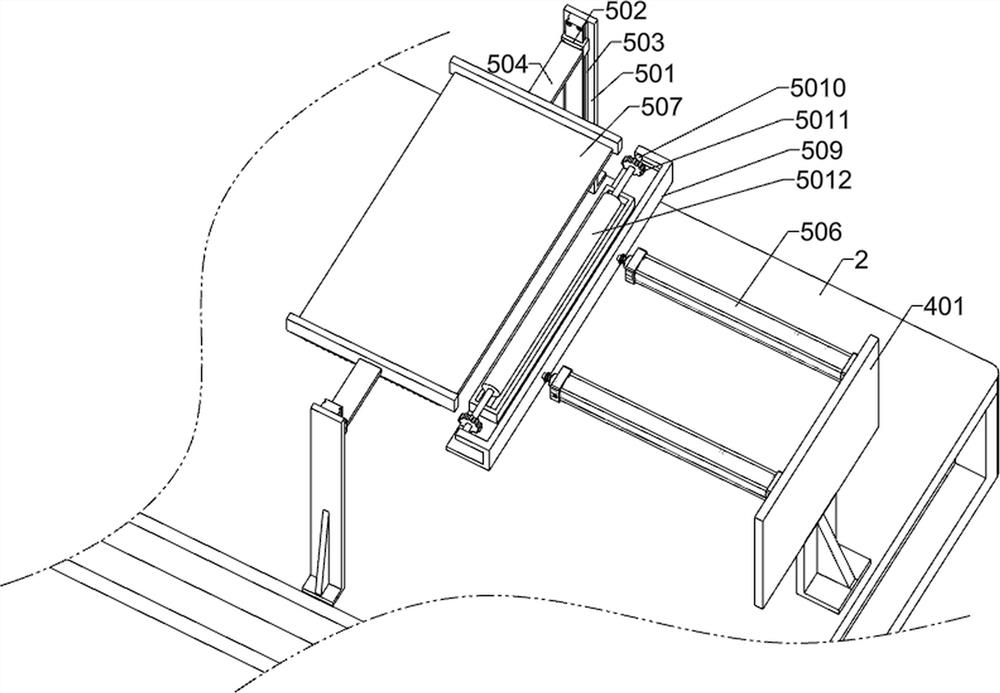

[0044] On the basis of Example 1, such as figure 1 with Figure 12-14 As shown, it also includes an adsorption unit; the middle part of the first mounting plate 2 is connected with the adsorption unit; Mounting plate 504, the second rack 505, cylinder 506, the seventh mounting plate 507, sponge board 508, the eighth mounting frame 509, the seventh transmission shaft 5010, the third gear 5011, the second pressure roller 5012, the collection box 5013 and The third scraper 5014; the middle part of the first mounting plate 2 is bolt-connected with two seventh mounting frames 501, and the two seventh mounting frames 501 are symmetrically arranged front and rear, and the two seventh mounting frames 501 are located between the two first electric motors. The outer side of the slide rail 201; the left side of the sixth installation frame 401 is fixedly connected with two cylinders 506, and the two cylinders 506 are arranged symmetrically front and rear; the opposite sides of the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com