Detection device and detection method for switch cabinet cable

A detection device and switchgear technology, applied in switchgear components, switchgear grounding devices, measuring devices, etc., can solve the problems of time-consuming and laborious, poor contact between incoming cable bushings and cable joints, and cable joint damage, etc. Achieve the effect of reducing disassembly time, realizing cable detection function, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Below in conjunction with accompanying drawing this embodiment is described in detail:

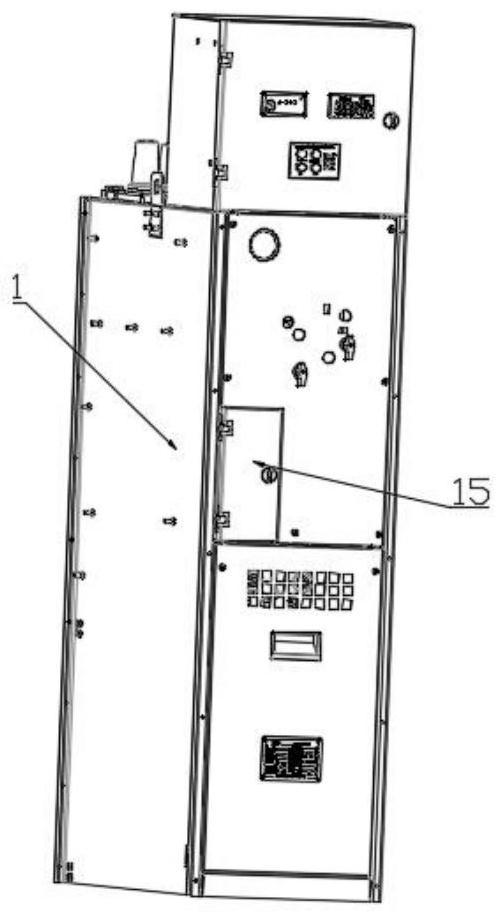

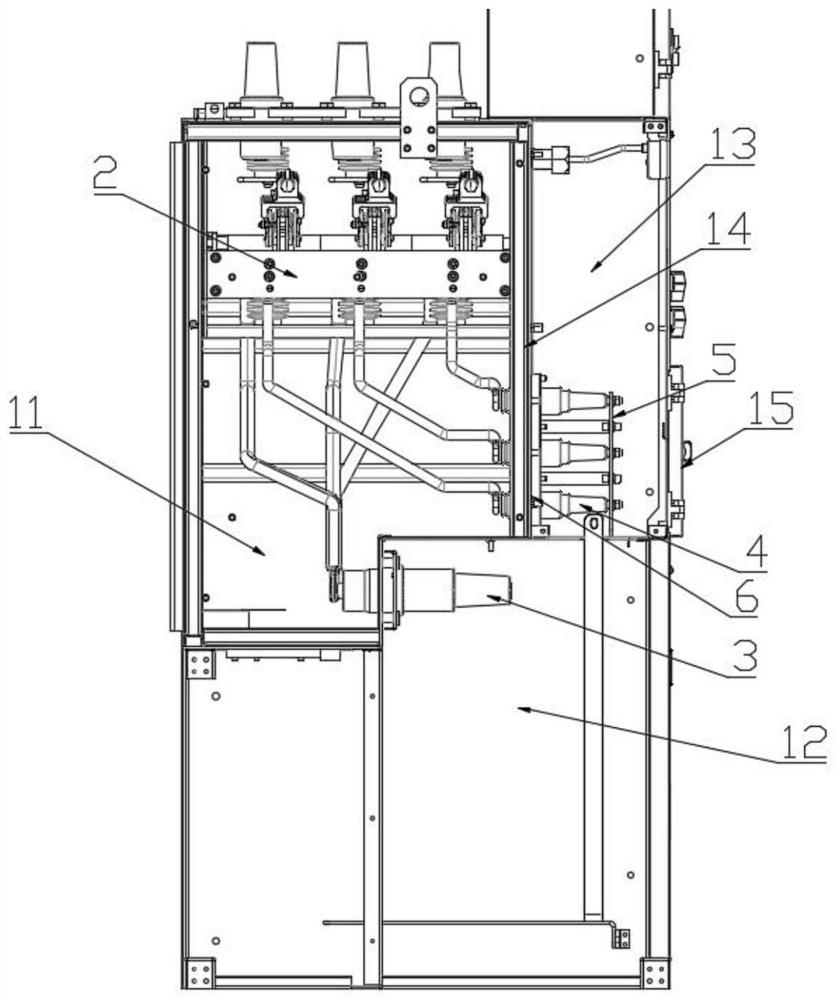

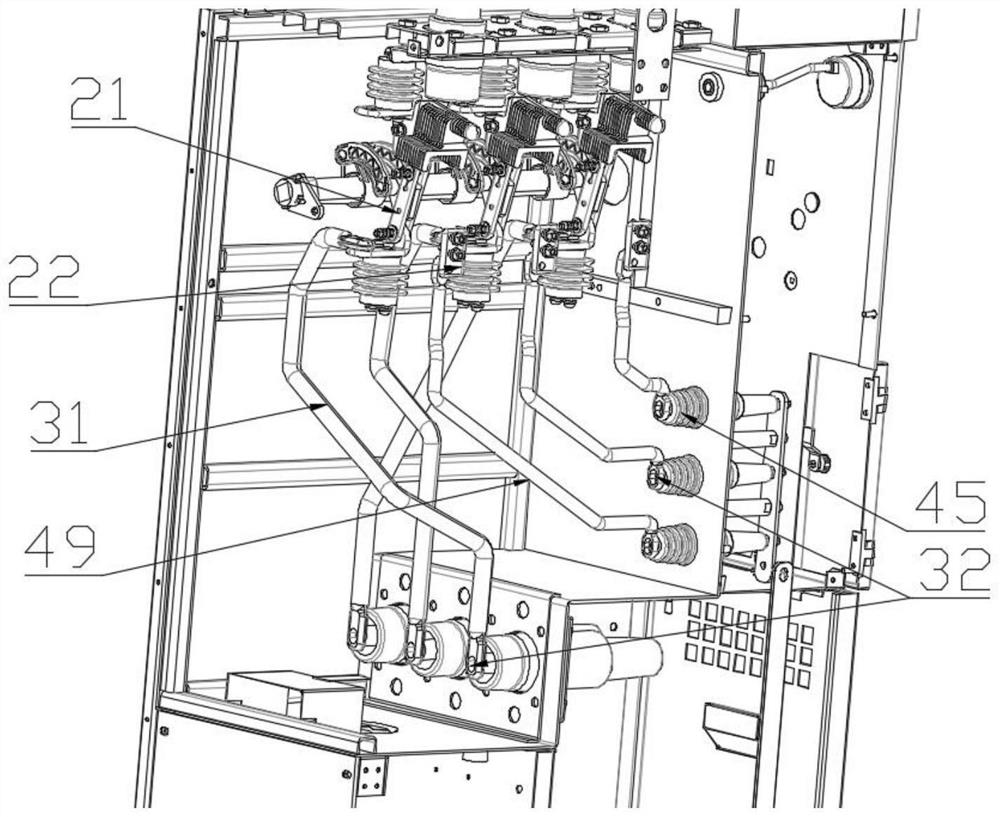

[0049] The present invention provides such Figure 1-8 The shown cable detection device of a switch cabinet includes a cabinet structure 1, and a switch assembly 2 arranged in the cabinet structure 1, and the switch assembly 2 includes three moving contacts 21 and three grounding contacts Head 22, the switch assembly 2 has a grounding state when the moving contact 21 is in contact with the grounding contact 22;

[0050] The cabinet structure 1 is provided with three cable inlet joints 3 respectively electrically connected to the three moving contacts 21, and three withstand voltage detection joints electrically connected to the three ground contacts 22 respectively. 4. Three incoming cables are connected to the three cable inlet connectors 3, the withstand voltage detection connector 4 can be used to connect an external withstand voltage test device, and the three withstand voltage...

Embodiment 2

[0061] This embodiment provides a detection method for a switch cabinet cable, which is applied to the detection device for a switch cabinet cable in Embodiment 1, and the detection method includes the following steps:

[0062] Step 1: first switch the switch assembly 2 from the closing state to the opening state, and then open the operation cabinet door 15 to disassemble the grounding copper bar 5 from the three withstand voltage detection joints 4;

[0063] Step 2: the pressure-resistant testing device is respectively installed on three described pressure-resistant detection joints 4;

[0064] Step 3: switch the switch assembly 2 from the opening state to the grounding state, so that the three cable inlet connectors 3 and the three withstand voltage detection connectors 4 correspond to form three detection paths;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com