Structure of cutting die stamping gas diffusion layer

A gas diffusion layer and knife die technology, applied in metal processing and other directions, can solve the problems of unsatisfactory size, appearance and wool length accuracy, unable to meet product accuracy requirements, etc., and achieve the effect of reducing production costs and meeting product accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that the use of words such as "first" and "second" to define parts is only for the convenience of distinguishing corresponding parts. Limitation of the scope of protection of the invention.

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] It can be understood that the present invention achieves the purpose of the present invention through some embodiments.

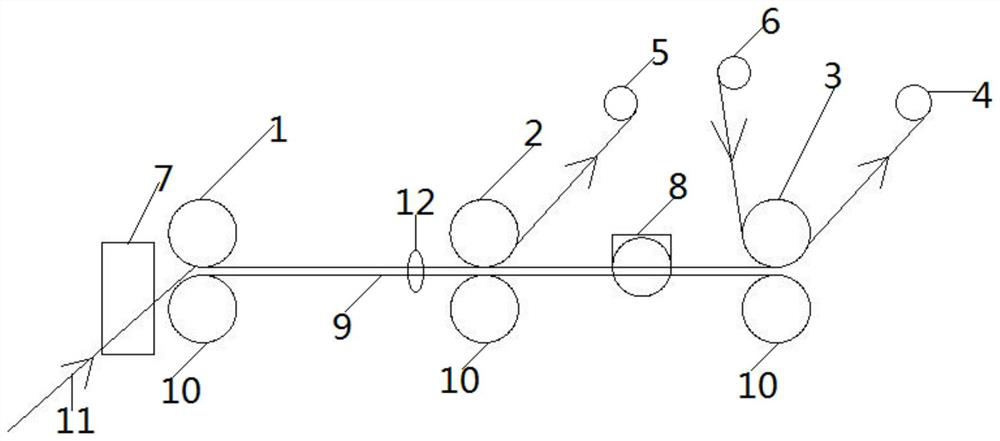

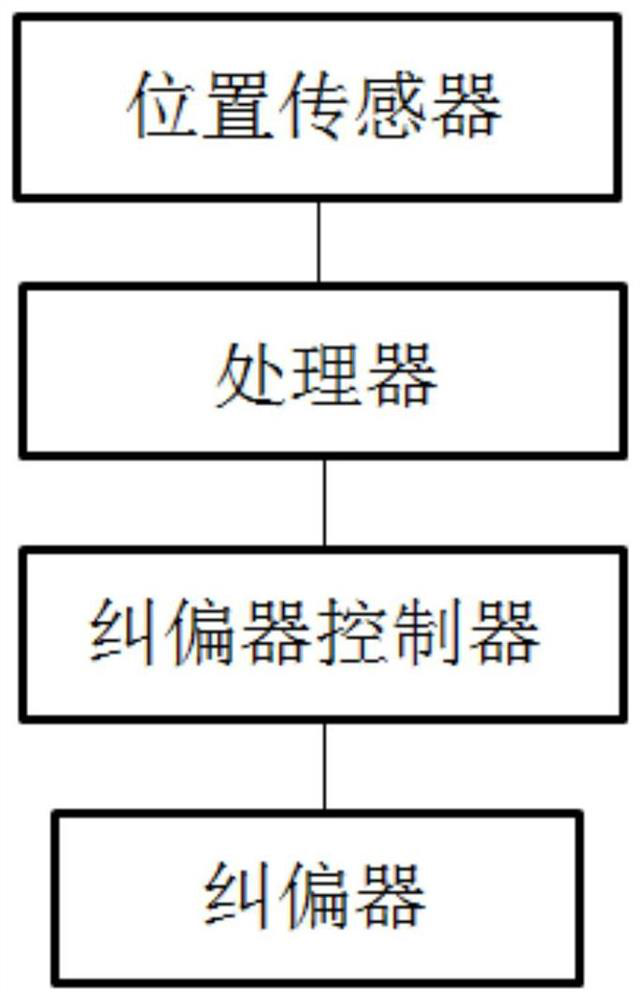

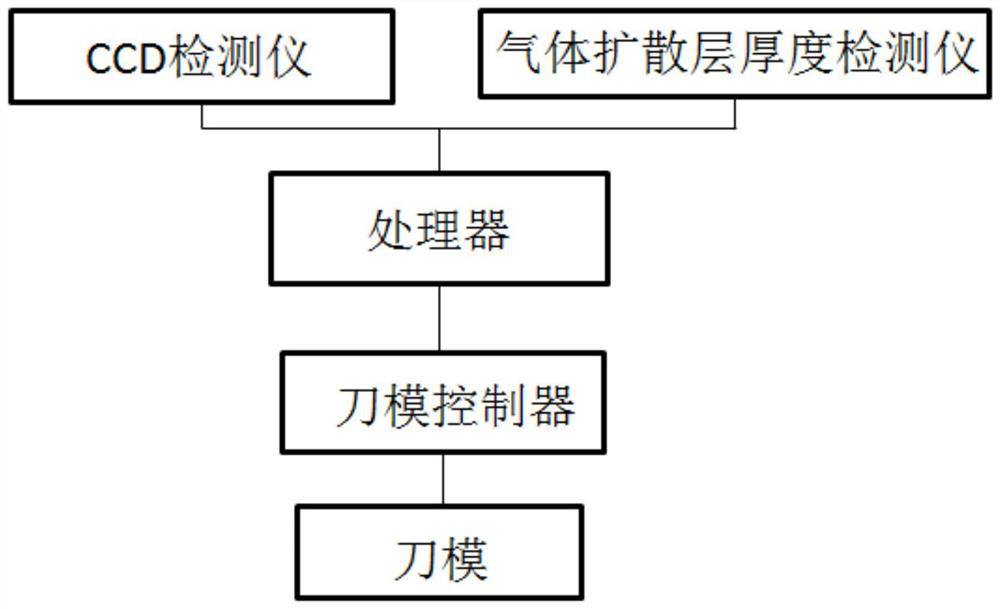

[0027] Such as figure 1 As shown, the present invention provides a structure for stamping a gas diffusion layer with a knife die, including: a gas diffusion layer and a transmission belt 9, a backing film is connected to the gas diffusion layer to form a gas diffusion layer 11 to be cut, and the transmission belt One end of the belt 9 is connected to the conveying roller 1, and the other end of the conveying belt 9 is connected to the winding member 4; one side of the conveying belt 9 is sequentially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com