Machine gun bullet box capable of discharging bullets in inclined mode and machine gun bullet supply system

A machine gun and ammunition box technology, applied in the direction of ammunition supply, offensive equipment, weapon accessories, etc., can solve the problems of large layout space, inability to eject smoothly, and instability of the ammunition chain posture, so as to reduce the overall horizontal size and improve the battlefield. Survival rate, the effect of reducing the resistance of the bomb supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

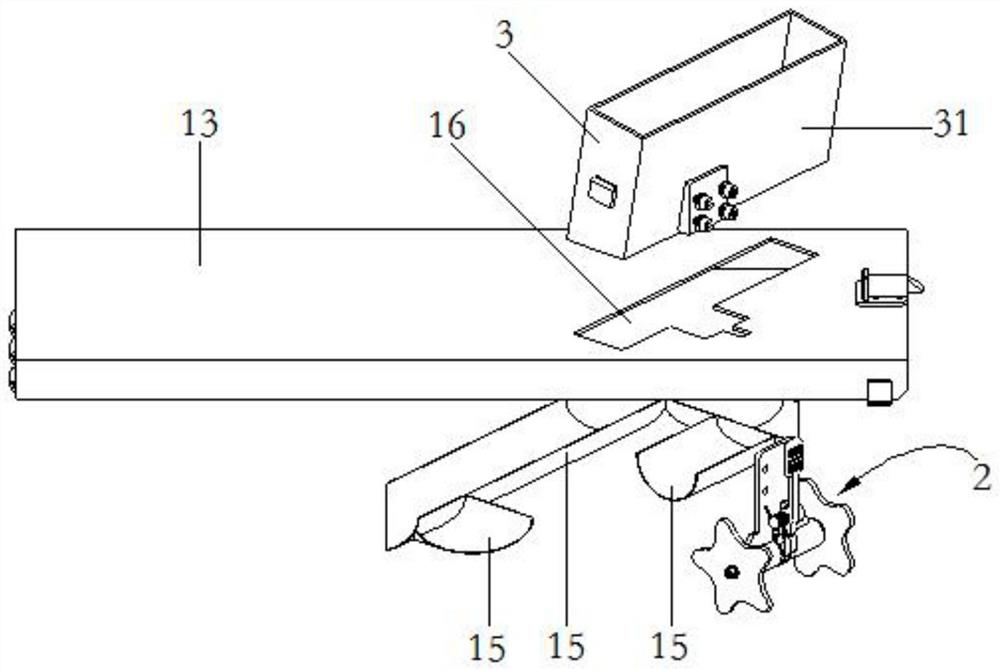

[0028] The embodiment of the present invention provides a machine gun magazine for oblique ejection, which includes a box body, and a bullet outlet 16 is provided on the top plate 13 of the box body and is connected with a bullet outlet groove 3 . The above box is preferably a square box. Above-mentioned ejection groove 3 is connected with machine gun bullet inlet by soft guide 4. The ejection slot 3 is preferably a square tube with the same size as the ejection opening 16, adapted to the size of the bullet, for example, the length is slightly greater than the length of the bullet, and the width is slightly greater than the thickness of the bullet chain 100; the ejection slot 3 The height can be set according to specific conditions.

[0029] In one of the examples, as Figure 1-Figure 3 as well as Figure 5-Figure 6 , there is an angle between the ejection groove 3 and the top plate surface (that is, there is an angle between the long side pipe wall 31 of the bullet ejectio...

Embodiment 2

[0031] An embodiment of the present invention provides a machine gun magazine, which can optimize the magazine in the first embodiment above.

[0032] An auxiliary ejection mechanism 2 is provided in the casing to improve the smoothness of the ejection of the cartridge case.

[0033] Such as Figure 3-Figure 5 The auxiliary ejection mechanism 2 includes a transition wheel 21 and an ejection power unit for driving the transition wheel 21 to rotate around its own axis, and a plurality of picking teeth 211 are formed on the rim of the transition wheel 21, so The transition wheel 21 is located near the bullet outlet 16 and the picking teeth 211 are suitable for engaging with the bullet chain 100 . The above-mentioned ejection power unit can adopt conventional rotating drive equipment such as motor; Optionally, the ejection power unit is connected with the axle 22 of the transition wheel 21, drives the axle 22 to rotate, and the transition wheel 21 is then arranged on the axle 22;...

Embodiment 3

[0039]An embodiment of the present invention provides a machine gun magazine, which can optimize the magazine in the first or second embodiment above.

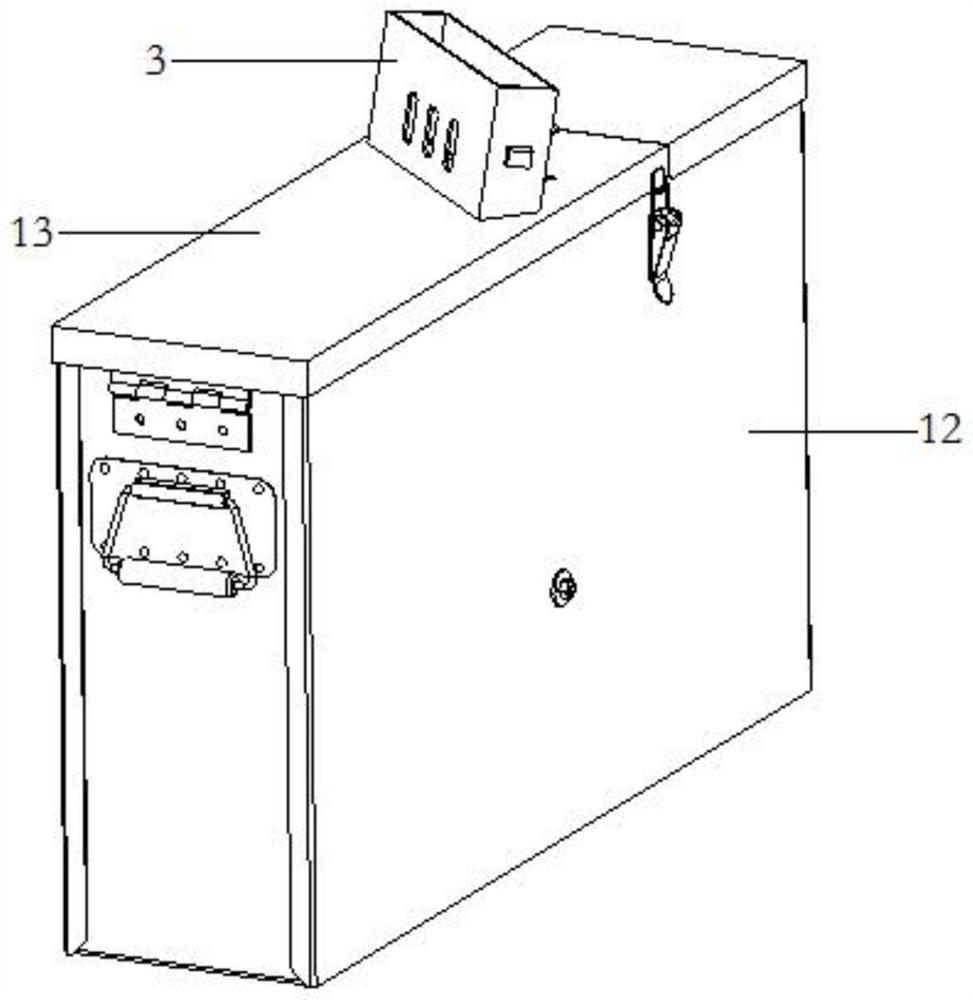

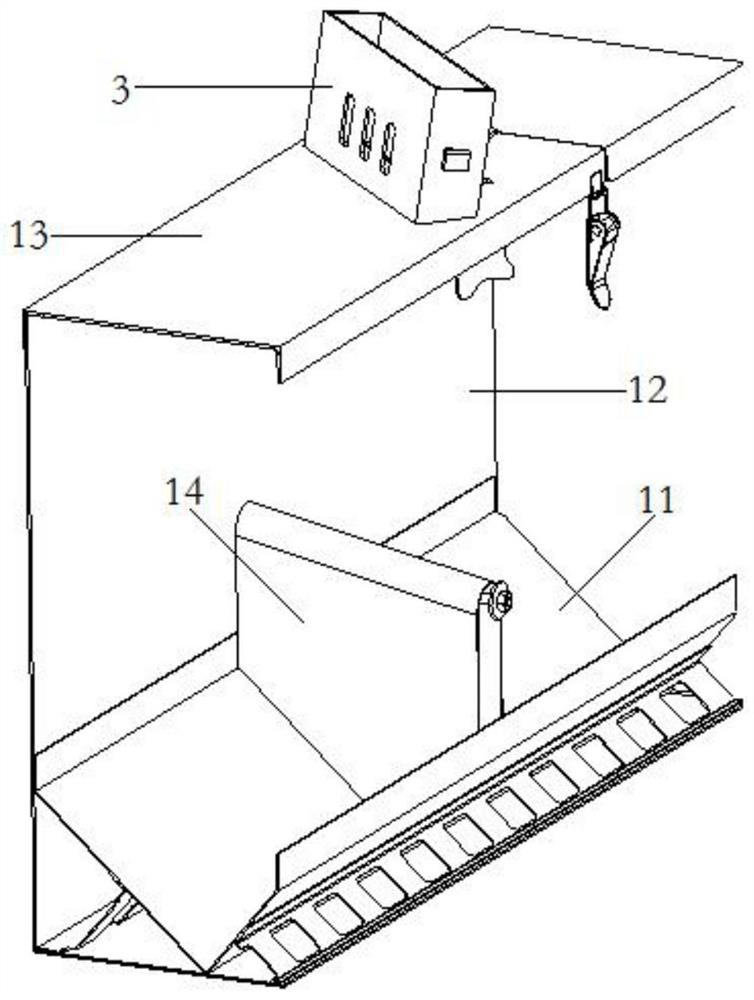

[0040] Such as figure 1 and figure 2 , the casing of the bomb box includes a bottom supporting plate 11, a multi-faceted box body side plate 12 and a top plate 13, and the bottom supporting plate 11, the multi-faceted box body side plate 12 and the described top plate 13 cooperate to form a box chamber , the bottom supporting plate 11 is a V-shaped plate.

[0041] In one of the embodiments, the above-mentioned bottom supporting plate 11 is connected with the multi-faceted box body side plate 12 to form a box body, and the above-mentioned top plate 13 is covered on the box body as a box cover, wherein, between the top plate 13 and the box body The detachable connection is convenient for taking and releasing the bullet chain 100 or for maintenance; conventional detachable connection methods can be used, and no examples are gi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com