Pipe body pressure test device and pipe body pressure test method

A technology of pressure testing and pipe body, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., which can solve the problems of poor versatility, low efficiency of pressure testing, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

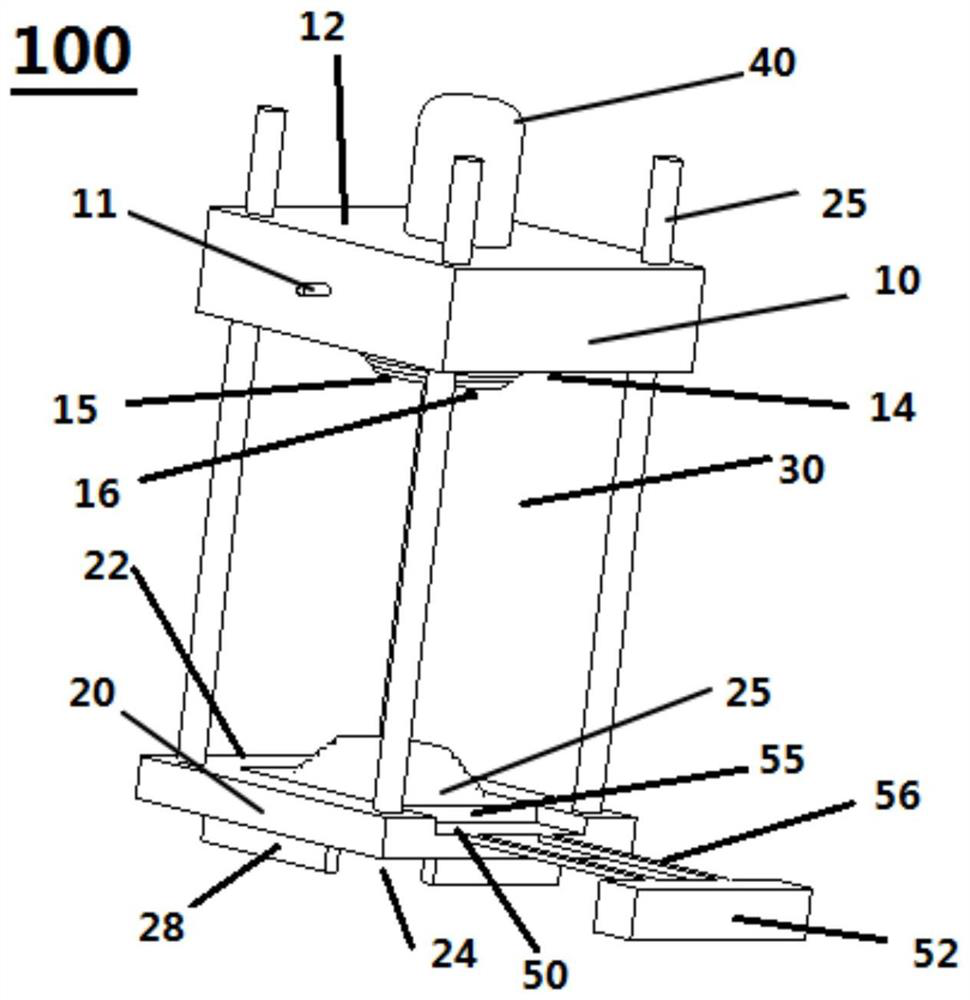

[0025] The present invention is introduced below by accompanying drawing.

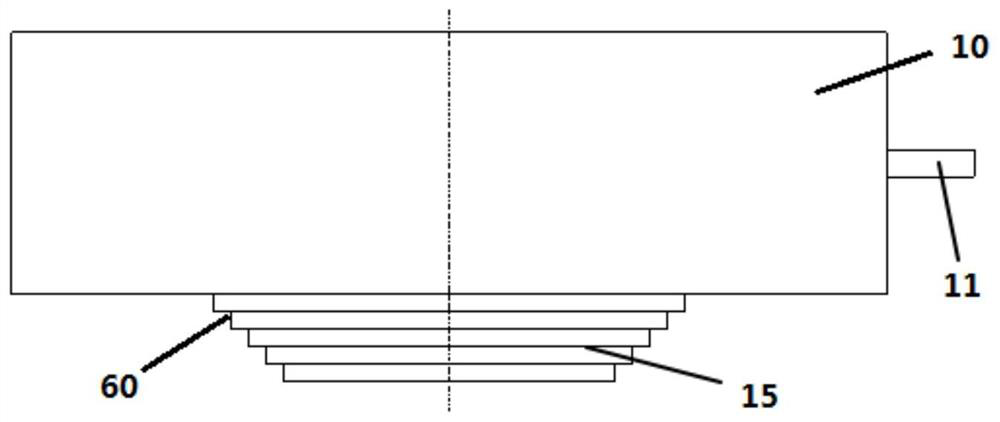

[0026] figure 1 A pipe pressure testing device 100 according to one embodiment of the invention is shown. Such as figure 1 As shown, the pipe body pressure test device 100 includes a top plate 10. The top plate 10 can be, for example, a circular or square shell. In the top plate 10, there are holes for the circulation of pressure test media such as gas and fluid. channel (not shown). A bottom pan 20 is disposed directly below the top pan 10, and the bottom pan 20 is also configured as a circular or square shell. The base plate 20 is arranged coaxially with the top plate 10 . The top plate 10 and the bottom plate 20 have a height difference in the vertical direction, so that a cavity 30 is formed between the top plate 10 and the bottom plate 20 .

[0027] In a preferred embodiment, the top plate 10 and the bottom plate 20 are connected by a plurality of lead screws 25 . Moreover, the lead screw 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com