Laminated stretched polyamide film

A polyamide film, polyamide technology, applied in the direction of lamination, layered products, lamination devices, etc., can solve the problem of film impact resistance, poor pinhole resistance, weak bonding strength, lamination strength, lamination Strength reduction and other problems, to achieve the effect of strong water-resistant lamination strength, good productivity, and economical productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

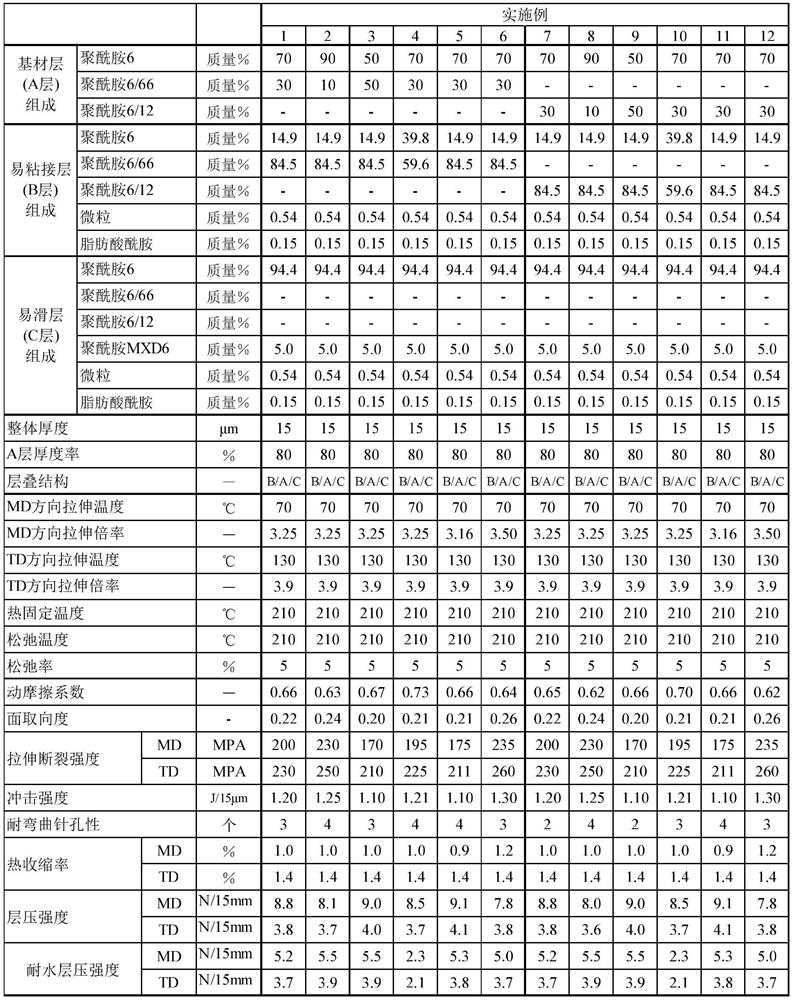

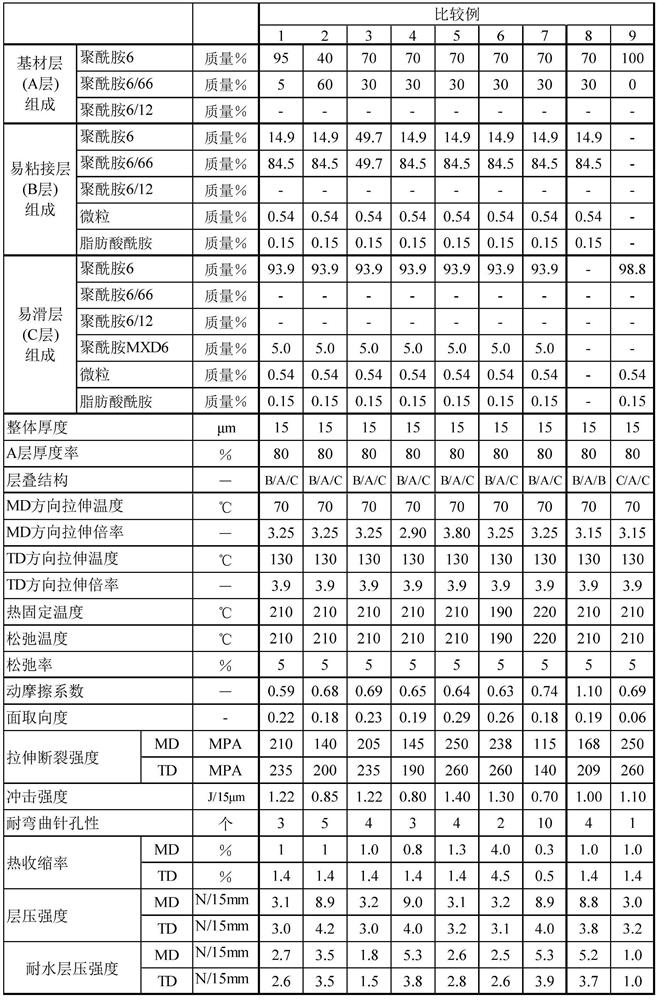

[0153] A device comprising 1 caliber 60mm extruder for A layer, 2 caliber 25mm extruders for B layer and C layer, and a co-extrusion T-die with a width of 380mm was used as the substrate layer (A layer ), polyamide 6 (relative viscosity 2.8, melting point 220° C.) and polyamide 6 / 66 copolymer (the ratio of polyamide 66 is 25 mass %, relative viscosity 2.8, melting point 198° C. ) is melt-extruded, and as an easy-bonding layer (layer B), polyamide 6 (relative viscosity 2.8, melting point 220°C) and polyamide 6 / 66 copolymer ( The ratio of polyamide 66 is 25% by mass, the relative viscosity is 2.8, and the melting point is 198°C), and silicon dioxide fine particles are added to contain 0.54% by mass, and ethylene bis stearic acid amide is added to contain 0.15% by mass. As an easy-slip layer (C layer), polyamide 6 (relative viscosity 2.8, melting point 220°C) and polyamide MXD6 are blended at a mass ratio of 95 / 5 and silica particles are added to contain 0.54% by mass. Ethylene ...

Embodiment 2~6

[0159] In addition to the film forming method of Example 1 above, except that the resin ratio of each layer and the film forming conditions were changed to the conditions shown in Table 1, a laminated biaxially oriented polyamide was produced in the same manner as in Example 1. membrane.

Embodiment 7

[0161] Laminated biaxially stretched poly Amide film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap