Knuckle forging die with double-layer bionic reinforcement

A steering knuckle and double-layer technology, applied in the direction of manufacturing tools, swaging presses, upsetting forging presses, etc., can solve the inconvenience of mold placement and clamping operations, inconvenience of mold activity adjustment control, and inconvenience of lifting device structure protection Splash-proof effects and other issues, to achieve the effect of improving the double-layer shaping effect, improving the protective effect, and improving the convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

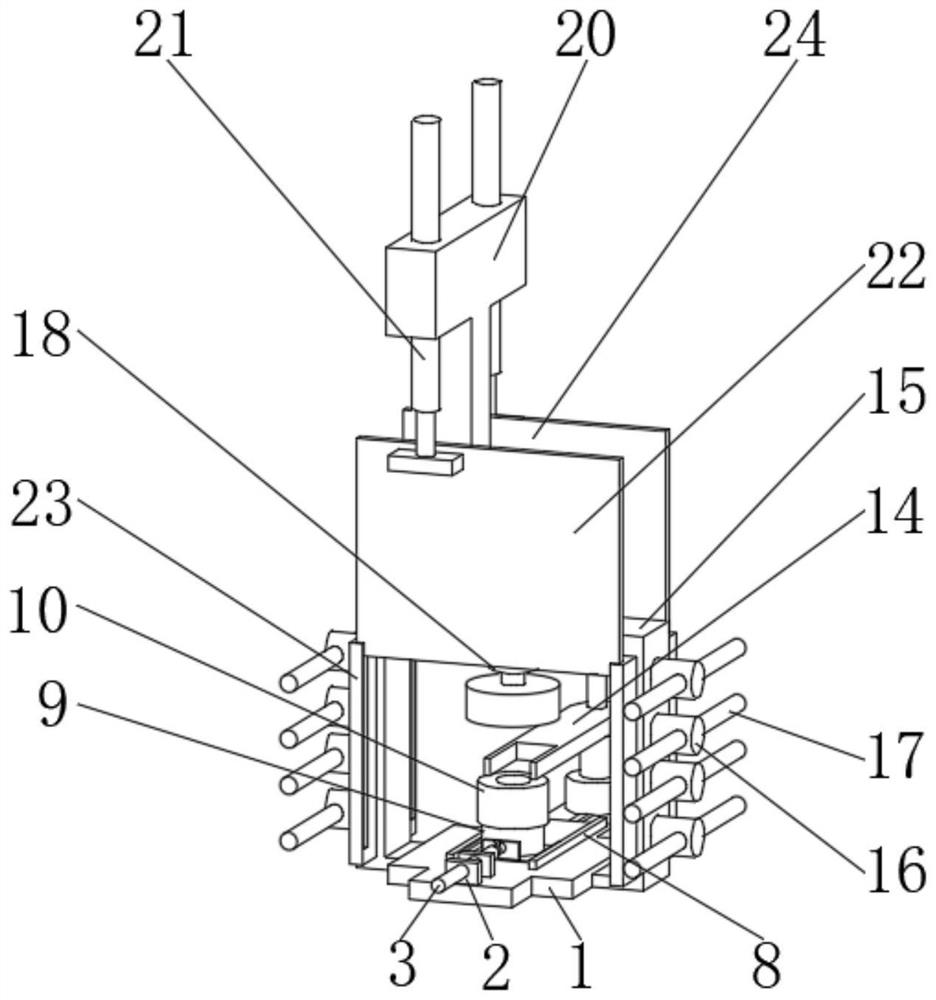

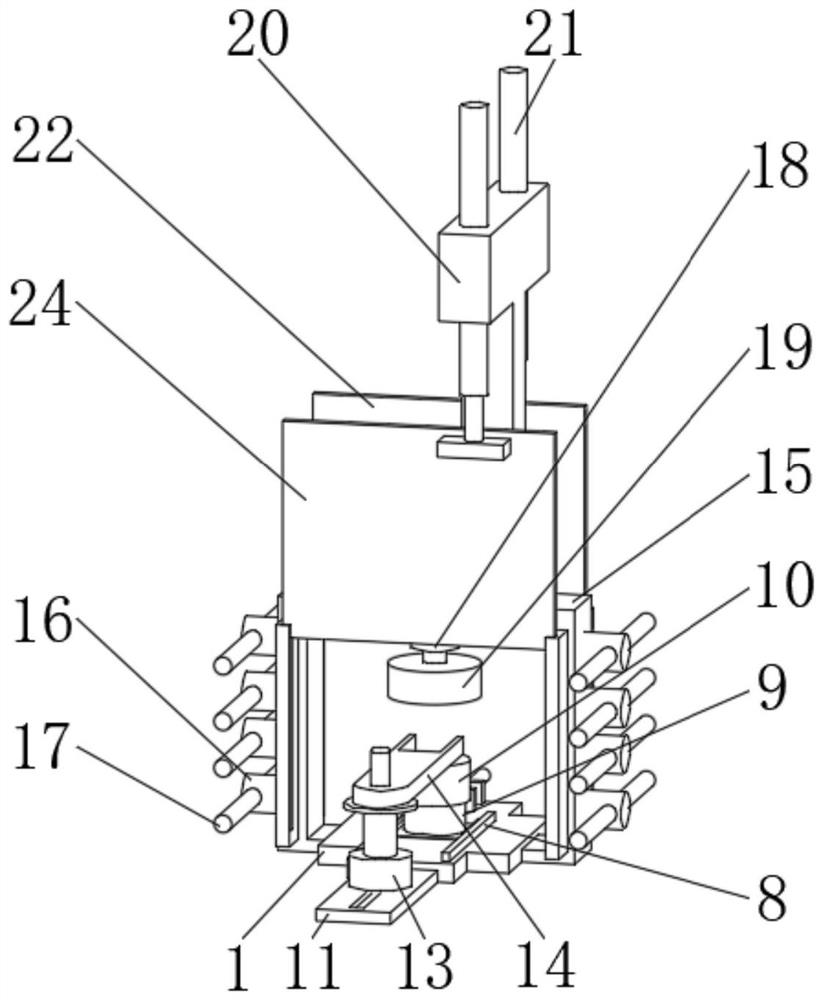

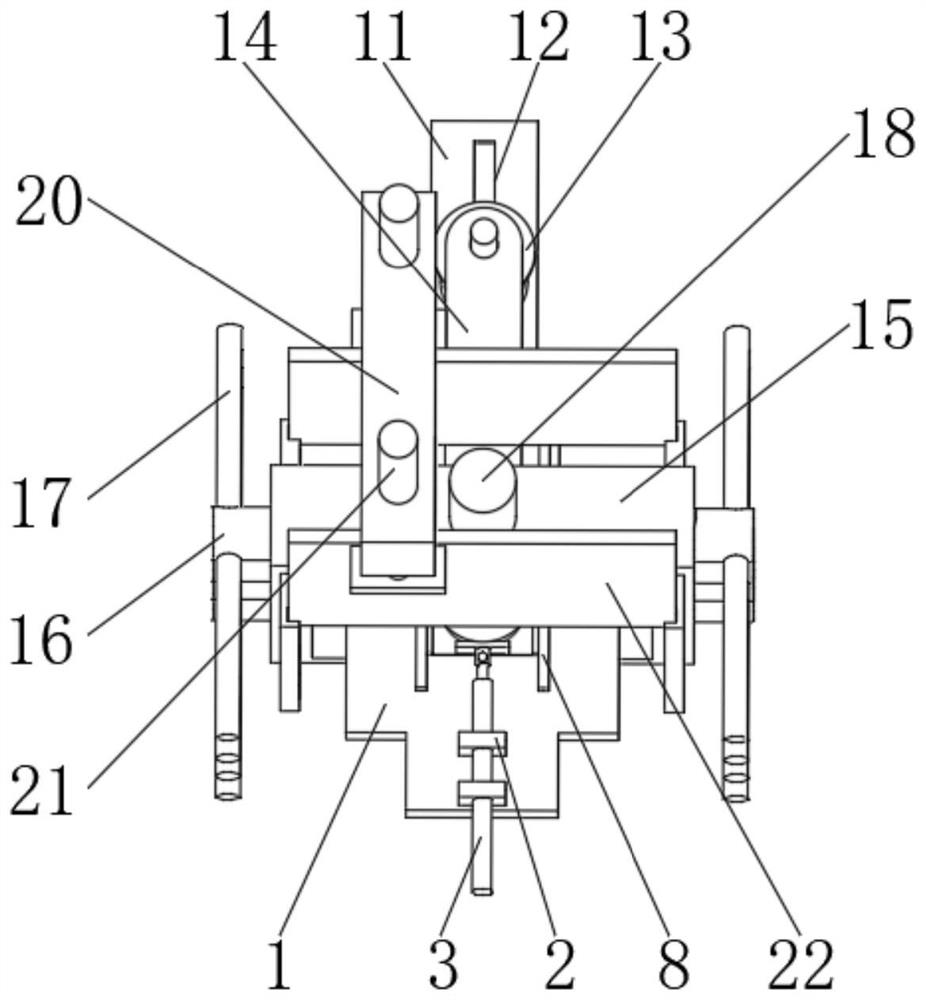

[0027] see Figure 1-4 As shown, a steering knuckle forging die with double-layer bionic reinforcement includes a bottom plate 1 and a support frame 15, a fixed plate 2 is arranged on the top of the bottom plate 1, and an electric telescopic rod 3 is installed on the inner side of the fixed plate 2, and the electric telescopic rod 3 is provided with a connecting sleeve 4, and the top of the connecting sleeve 4 is provided with a fixing nail 5, the end of the connecting sleeve 4 is connected with a connecting plate 6, and the end of the connecting plate 6 is provided with a moving plate 7, and the moving plate The limit plate 8 is arranged on the side of the moving plate 7, the bottom mold cover 9 is arranged at the middle position of the moving plate 7, and the top mold cover 10 is arranged on the top of the bottom mold cover 9, and the extension plate 11 is arranged on the back of the bottom plate 1, and the extension plate The inner side of 11 is provided with a sliding rail...

Embodiment 2

[0032] see Figure 1-5 As shown, compared with Example 1, as another embodiment of the present invention, the support frame 15 is arranged on the side of the bottom plate 1, and the side of the support frame 15 is provided with a fixed column 16, and the inside of the fixed column 16 is provided with a Protective rod 17, hydraulic cylinder 18 is installed in the middle of support frame 15, and the end of hydraulic cylinder 18 is provided with forging block 19, and the top of support frame 15 is provided with top frame 20, and the inner side of top frame 20 is provided with pneumatic rod 21. The end of the pneumatic rod 21 is provided with a first splash guard 22, and the outer side of the first splash guard 22 is provided with a sliding frame 23, and the side of the first splash guard 22 is provided with a second splash guard 24 .

[0033] The protective rod 17 and the fixed column 16 are nested and connected, and the fixed column 16 is provided with four pairs symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com