Consumable support for 3D printing and mounting method thereof

A technology for 3D printing and consumables, applied in the direction of additive processing, manufacturing auxiliary devices, etc., can solve the problems of loose consumables and poor stability, and achieve the effect of avoiding relaxation, improving stability and avoiding interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

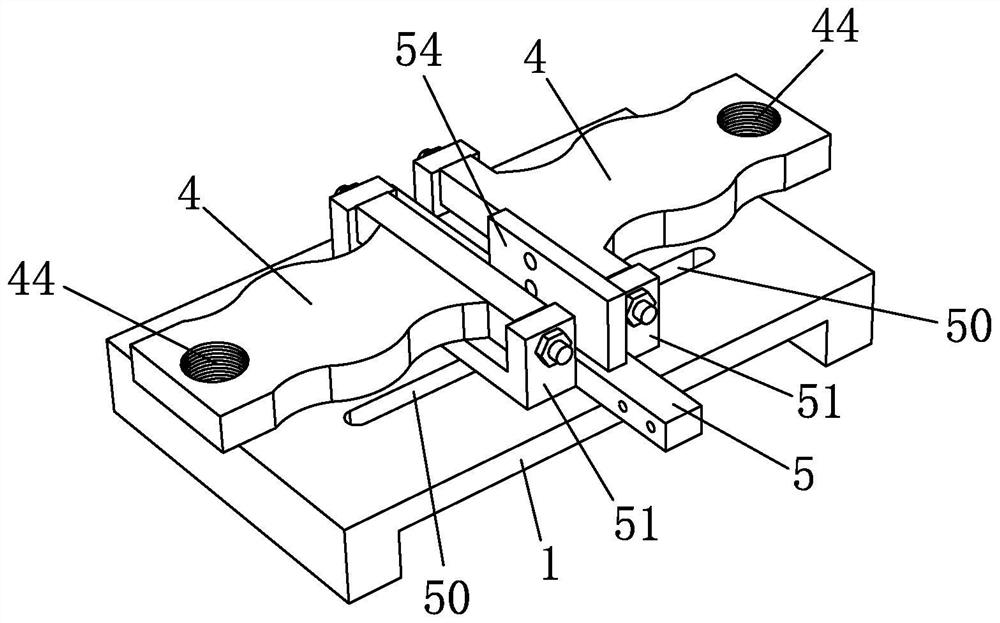

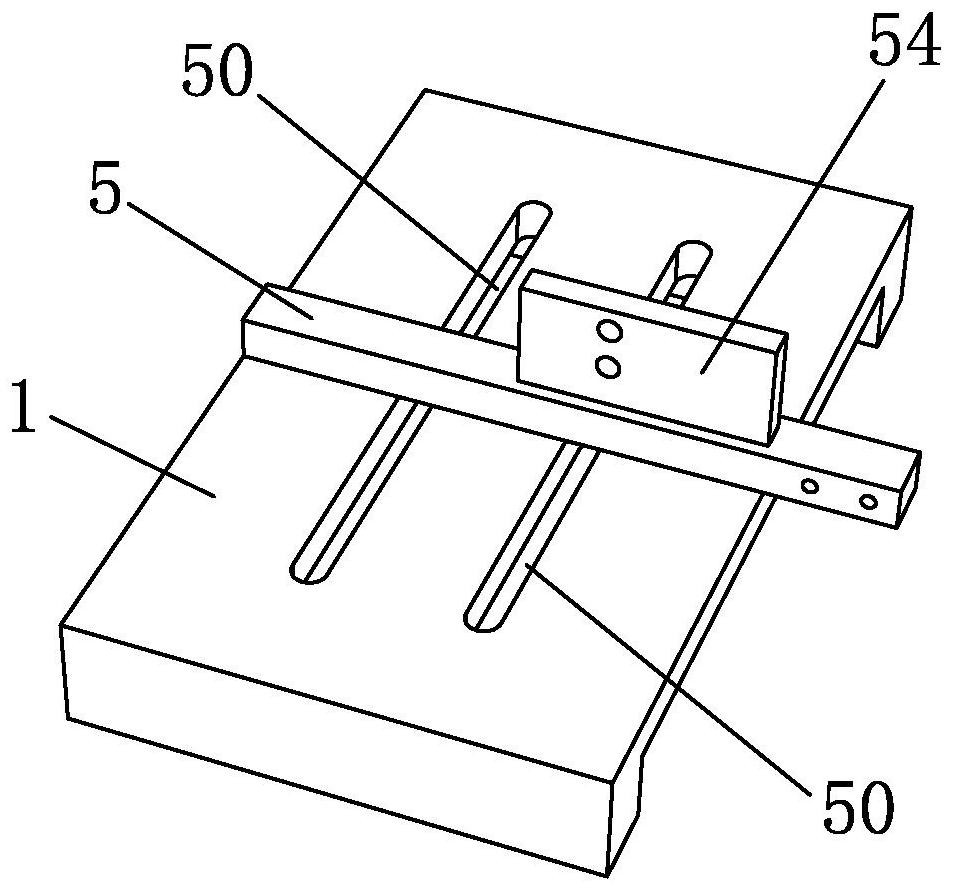

[0055] like Figure 1 to Figure 20 As shown, it is a consumable support for 3D printing according to the present invention, which includes a base 1 and a wire tray 2. The center line of the wire tray 2 is used as a horizontal plane C, the area above the horizontal plane C is the first support area A, and the area below the horizontal plane C is The second support area B, the first support area A and the second support area B are not technical characteristics of the present invention, but in order to more clearly illustrate the first pressing mechanism and the second pressing mechanism, the wire material tray 2 is divided into areas , consumables 3 are set on the filament tray 2.

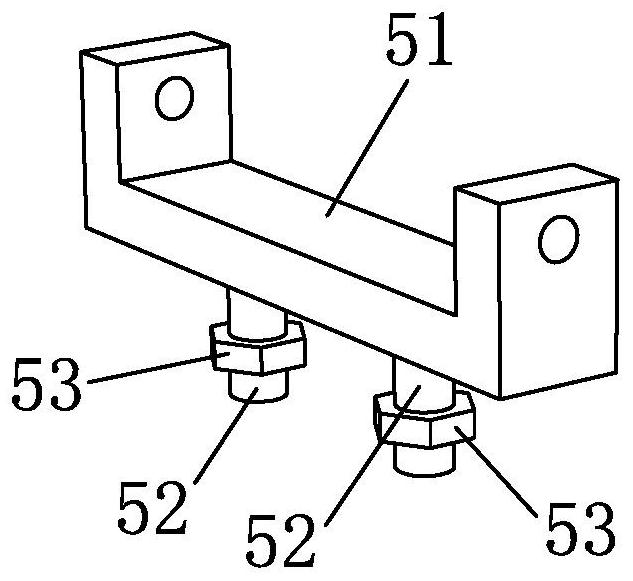

[0056] The present invention also includes a supporting plate 4, a connecting plate 5, a first pressing mechanism 6 and a second pressing mechanism 7, and two supporting plates 4 are vertically and symmetrically installed on the base 1, and the wire material tray 2 is installed in the middle of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com