Composite material insulation cantilever supporting device structure

A support device and composite material technology, applied in the direction of overhead lines, etc., can solve problems affecting the normal operation of the railway system, wrist arm dirt, insulation arm system damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

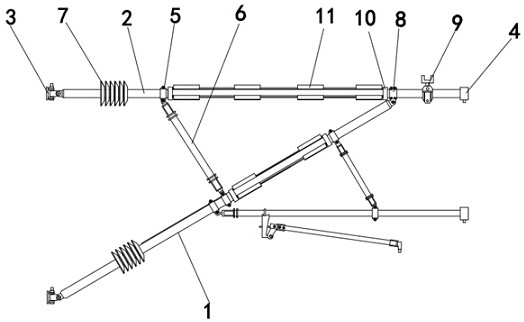

[0023] see Figures 1 to 7 , a schematic diagram of the planar structure and a schematic diagram of the three-dimensional structure of a composite material insulating wrist-arm support device.

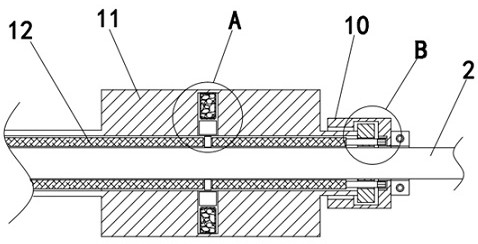

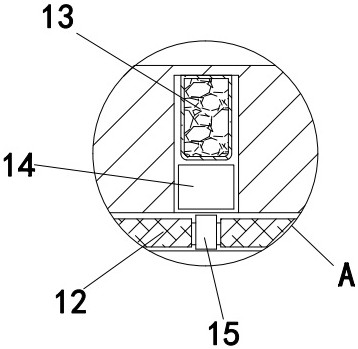

[0024] A composite material insulation wrist arm supporting device structure, comprising a flat wrist arm 2, a support tube clip 5 is fixedly installed on the left side of the flat wrist arm 2, a wrist arm support 6 is connected to the lower end of the support tube clip 5, and the right side of the flat wrist arm 2 is fixed Sleeve double ears 8 are installed, and the lower end of the sleeve double ears 8 is connected with a slanted arm 1, and the lower end of the arm support 6 is connected with the slanted arm 1, and the right end of the flat arm 2 is fixed with a cap 4, and the flat arm 2 An umbrella skirt 7 is installed on the outside of the left end, and an umbrella skirt 7 is also installed on the outside of the left end of the oblique wrist arm 1. A cleaning mechanism 10 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com