Flatness detection device for road engineering construction

A detection device and road engineering technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of reducing the occupied area of the device support, small shrinkage deformation limit, inconvenient to carry and transfer, etc. Simple, easy to carry and transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

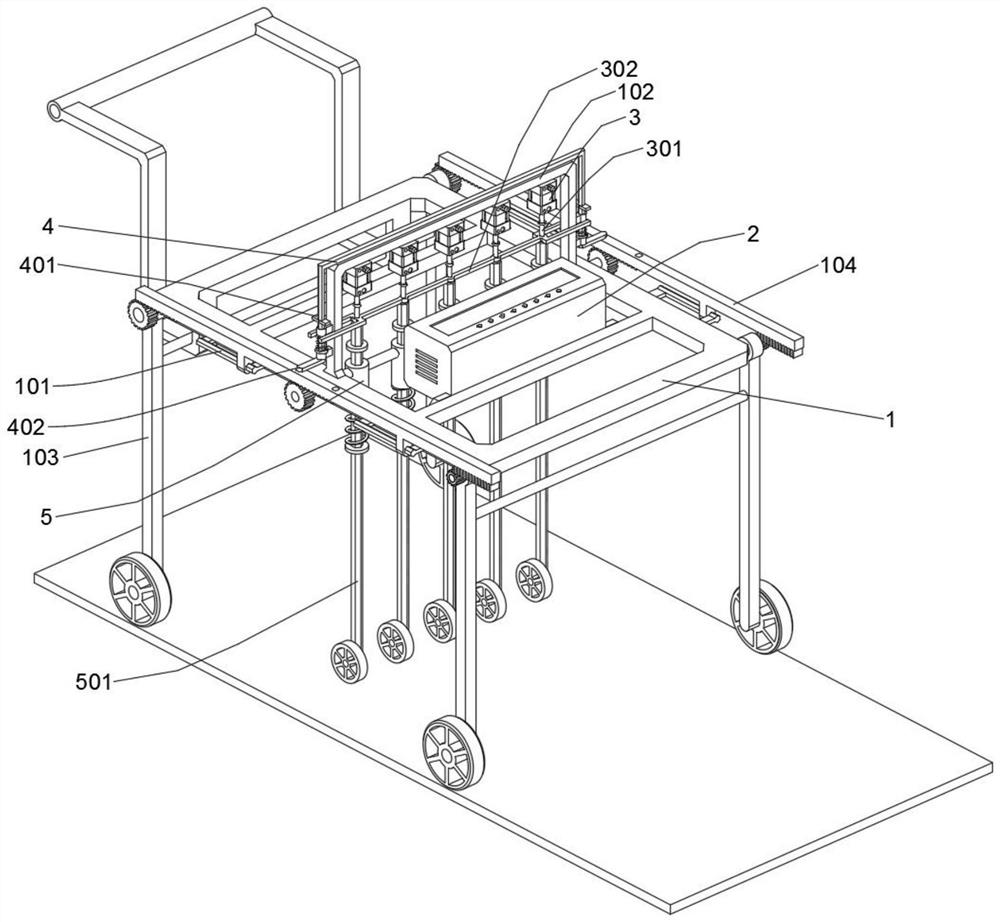

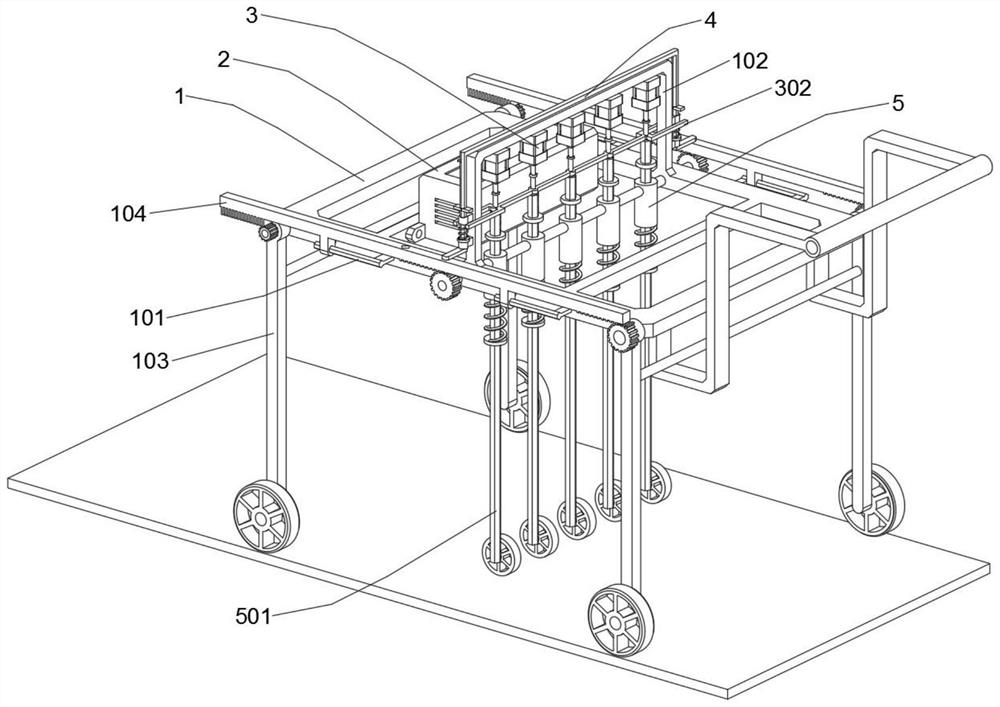

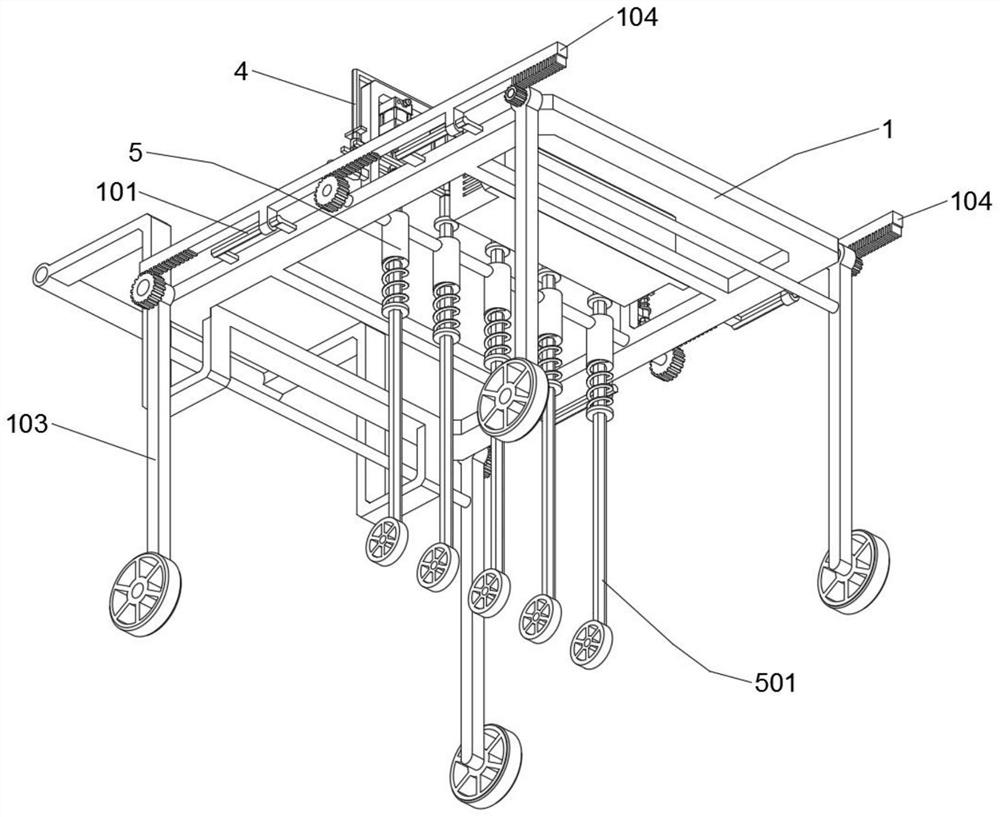

[0031] see Figure 1 to Figure 8 ;

[0032] The invention proposes a flatness detection device for road engineering construction, comprising: a vehicle frame 1; the vehicle frame 1 has a rectangular frame structure as a whole, and a handle bar is fixed at the bottom position of the rear end by welding two Z-shaped braces, and The inside of the frame 1 is welded symmetrically with two cross braces, wherein an electric control box 2 is installed on the front cross brace; Four hexagonal positioning shafts 101 supported longitudinally are welded on the side struts in front and back symmetry; two racks 104 are symmetrically slidably installed on the four hexalodal positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com