A paint spraying device for the production of combined wardrobes

A wardrobe and end face technology, applied in the direction of spraying device, can solve the problems of difficult maintenance, uneven paint spraying, easy oil leakage of the cylinder, and achieve the effect of reducing floor space, reducing manual participation, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

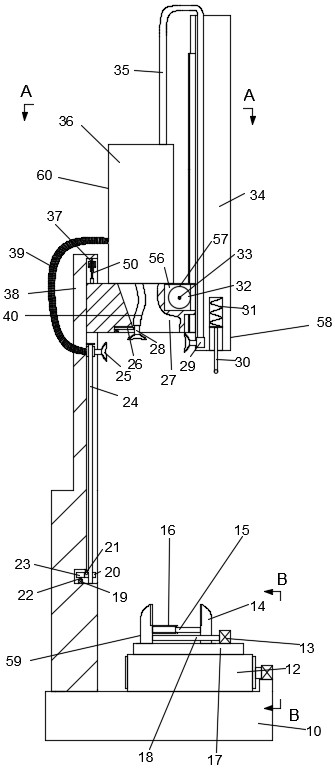

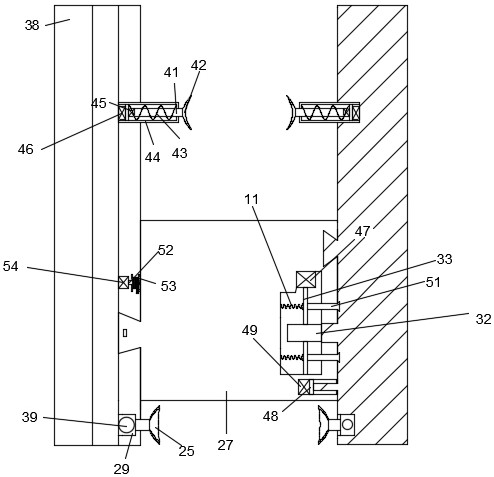

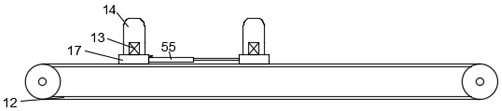

[0021] like Figure 1-Figure 4 , according to an embodiment of the present invention, a paint spraying device for the production of a combined wardrobe includes a base 10, the upper end surface of the base 10 is fixedly connected with a base block 38, the base block 38 is slidably connected with a sliding block 27, and the sliding block 27 is provided with a control cavity 56, the base 10 is provided with an adjustment mechanism 58, a paint spraying mechanism 60 and a fixing mechanism 59, the fixing mechanism 59 can clamp the combined wardrobe, and the spraying mechanism 60 can complete the painting of three surfaces ;

[0022] The adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com