Clutch device of washing machine roller supporting shaft

A technology of a washing machine drum and a clutch device, applied in the field of washing machines, can solve the problems of difficulty in taking out and washed linen, extremely high strength requirements, no economic value, etc., and achieves high washing efficiency, saving production time, and the overall structure is stable and reliable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] First of all, the original design intention of the present invention is explained. The washing machine is a necessary electrical product in a modern family, which brings many conveniences to people's life. Drum washing machines, vertical drum washing machines and isolated drum washing machines, when the drum washing machine is working, the cabin cover needs to be closed so that the washing machine drum can work. The existing washing machine drum support shaft clutch device has a complex structure, long assembly time, and relatively high production cost. High, during the washing process, the overall rigidity of the drum and the stability during elution are relatively poor. Therefore, the present invention designs a clutchable device for the drum support shaft of a washing machine.

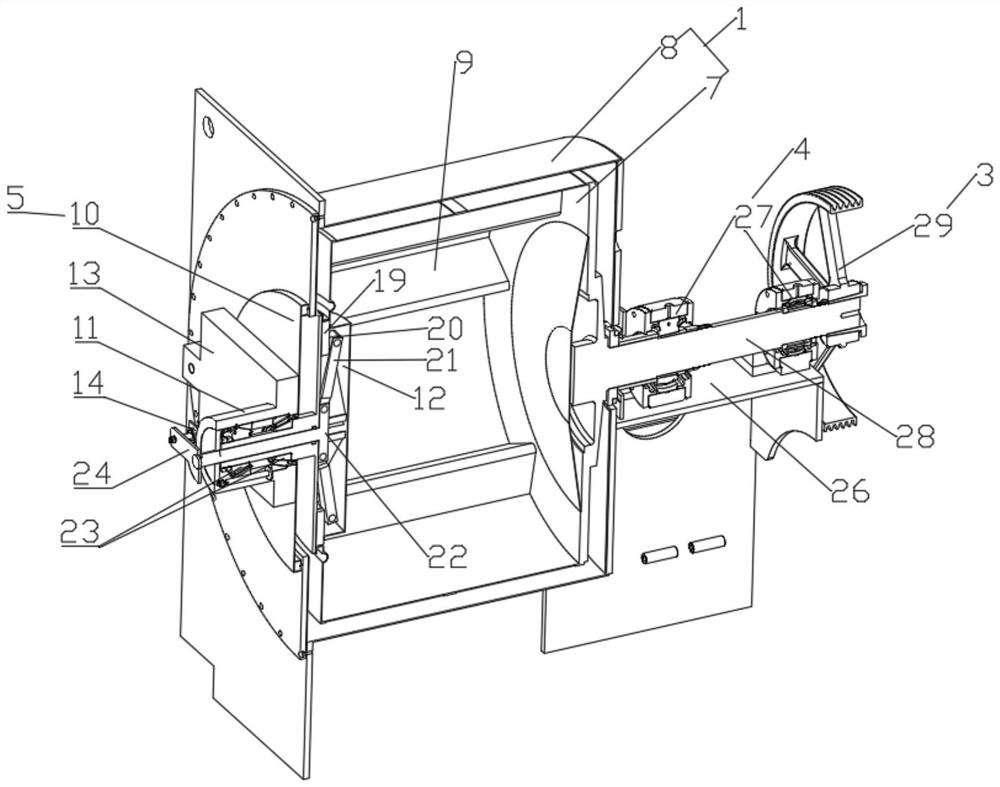

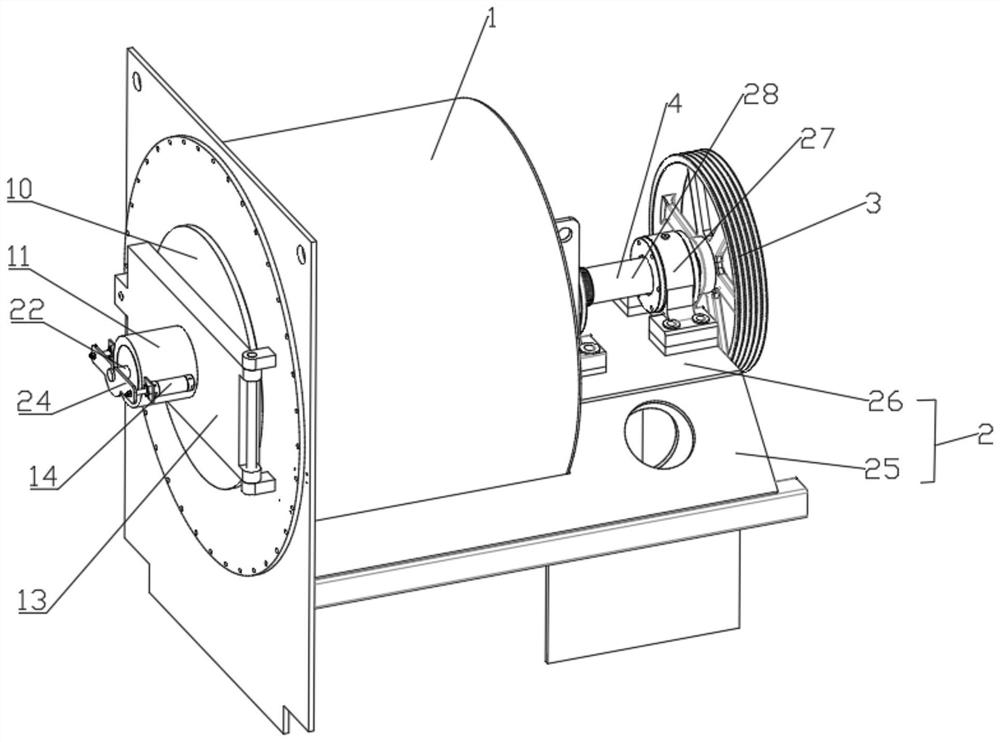

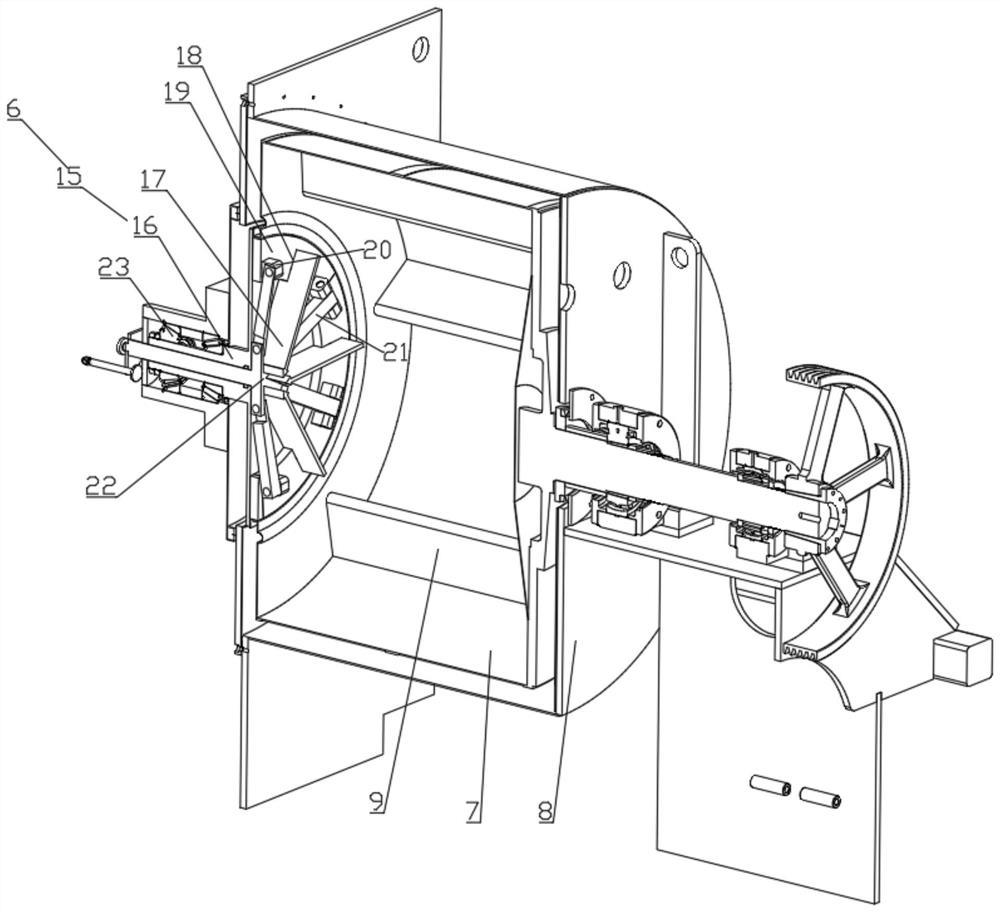

[0031] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 4 As shown, a washing machine drum supporting shaft clutchable devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com